FWS933FS3 Frigidaire Washer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

replace broken drive belt

carefully pry up on front washer top to release plastic keeper pins,remove 2 phillips screws from beneath lower front washer panel,slightly lift upward on panel to release.remove old broken belt,push new belt beneath large tub pulley,put belt on small motor pulley,push back belt tension /idler arm,start belt on large tub pulley,turn tub pulley by hand to run belt on,release tension on idler arm.replace front panel and lower top.WALAAH!!!! you are done.

Parts Used:

-

rodney from fairfield bay, AR

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

276 of 308 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

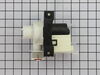

would't spin all water out or rinse out clothes

uplugged washer took front off washer 2 screws pryed up top pump was mounted with 2 screws and 2 wires took off found change in pump and the fins to pump worn off ordered part off line the wait for part was longer than the amount of time to fix problem and cost of part saved me about $25-35 if I was to buy local worth wait save money and fix problem washes like new spins and drains all water from tub.

Parts Used:

-

kenneth from willard, OH

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Pliers, Screw drivers

166 of 202 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

After a full cycle the washer would not drain the water

After reading the possiblilities of problem, I determined that the drain pump was not working; therefore I ordered a new one. When I opened the washer to replace the part, I found out that the pump was working but the filter was stuffed with pieces of rubber that came out from a rug I washed. Once all the stuff was removed, the washer worked just fine. PartSelect was very gracious to accept the returned with not questions asked!! Thanks partSelect.

Parts Used:

-

sara from North Miami, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

81 of 90 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

water leaking on floor

Removed two screws at bottom of front panel, removed front panel. Used pliers to remove hose clamp on drain hose. Fished hose out of chassis and installed new hose. Tested for leaks.

Parts Used:

-

Edward from New Smyrna Beach, FL

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers

60 of 76 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

pump very noisy, failing.

Disconnect water and electricity.

Shop-vac out the water in the internal drain hose.

Remove back cover, tip washer on side to gain access.

Un-clamp rubber drain hose,unscrew pump and remove.

Cleanout filter cup (yuk!) find coins and hairpins.

Attach drain hose to new pump and re-install with hose clamps from hardware store because spring clamps were impossible (arthritis in fingers).

Reconnect water and electricity.

Test for leaks and tighten clamps if necessary.

Shop-vac out the water in the internal drain hose.

Remove back cover, tip washer on side to gain access.

Un-clamp rubber drain hose,unscrew pump and remove.

Cleanout filter cup (yuk!) find coins and hairpins.

Attach drain hose to new pump and re-install with hose clamps from hardware store because spring clamps were impossible (arthritis in fingers).

Reconnect water and electricity.

Test for leaks and tighten clamps if necessary.

Parts Used:

-

John from Mason, MI

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers

51 of 55 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer wouldn't spin.

The problem with my very old washer was that the tension spring had broken long ago and I had jerry-rigged it in place with a cable tie. It would work, but you had to give the drum a spin by hand when it hit the spin the cycle. This probelm further caused the premature wearing of the drive belt, due to slippage. I ordered both a new spring and a new belt. Upon their arrival, I removed the two screws holding the front panel and lowered it off and out of the way. The old, worn belt was very easy to remove, as there was very little tension on it. Next I attempted to remove the washer that holds the idle arm on. It is in a very awkward spot, and it appears the the washing machine is sort of built around it. I bent it gradually with locking pliers until I could force it off with the blade of a flat screwdriver. Then the idler arm was easy to lower of its axle by twisting the drum a bit and pulling it to one side. I put the new spring into the idler arm, making sure the plastic bushing was in place and replaced the arm. I then repositioned to belt and replaced the front panel. It works great now.

Parts Used:

-

garland from Morganton, NC

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers

55 of 70 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Agitator Drive Block wore out

Removed fastening screw and Agitator. Removed and replaced Agitator Drive Block. Replaced and fastened Agitator. Done in 5 min.

Ordered part around noon. Shipping was 3-5 days. Part arrived in LESS than 24 hours.

Very happy camper here!

Ordered part around noon. Shipping was 3-5 days. Part arrived in LESS than 24 hours.

Very happy camper here!

Parts Used:

-

James from Somerville, MA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

68 of 114 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

bearing and seal at top of transmission went bad causing oil from transmission to stain clothes

I removed front and top of washer to get acess to the tub. removed cap to tub along with inner tub and agitator. the hardest part is removing the springs on the bottom and tilt it forward to get tub out. removed belt, pulley and bolts holding transmission in place. reassemble using silicone grease on seals and washers. works great now

Parts Used:

-

dave from port sanilac, MI

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers, Socket set

56 of 84 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

knob broke

-

Zackary from Fort Collins, CO

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

49 of 64 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Worn belt, faulty snubber. Washing machine was 'walking' during spin cycle.

Unplugged machine.

Turned off water supply.

Removed front panel.

Pushed in on belt tensioner, removed old belt, replaced with new belt.

Used pry bar to lift the base assembly high enough off the snubber to remove it. Partially propped it with 2x4 wood scraps.

Used bent clothes hangar to remove old snubber ring, to protect my hands.

Replaced snubber, arrow pointing up.

Carefully lowered base assembly.

Replaced front panel.

Turned water back on, plugged back in, washing machine no longer 'walks'.

Remember to check the washer against a level if you moved the machine.

Turned off water supply.

Removed front panel.

Pushed in on belt tensioner, removed old belt, replaced with new belt.

Used pry bar to lift the base assembly high enough off the snubber to remove it. Partially propped it with 2x4 wood scraps.

Used bent clothes hangar to remove old snubber ring, to protect my hands.

Replaced snubber, arrow pointing up.

Carefully lowered base assembly.

Replaced front panel.

Turned water back on, plugged back in, washing machine no longer 'walks'.

Remember to check the washer against a level if you moved the machine.

Parts Used:

-

Steven from Jacksonville, IL

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

43 of 52 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer not spinning, water leaking out bottom

My first step was to download and print out the parts diagrams from the manufacturer's website. With a basic idea of what I needed to get to I first removed the agitator cap and the agitator and right off I found a broken bolt on plate lock bracket that holds trunnion which supports and connects the tub to the transmission drive shaft. I replaced the bolt and put it back together and gave it a test run. Spun very nicely now but water was going everywhere. Unfortunately I found that when the bolt broke the tub had slipped down and ripped the rubber "tub seal assembly". To get to the seal I ended up tearing the machine completely down and removing the whole motor and transmission assembly out of the unit. It may be possible to get at the seal without doing this but I'm not 100% sure. To get the whole unit apart I did the following: Remove the front panel by removing the two screws located at the very bottom of the panel and lifting up and out .Remove the top/lid by removing two screws underneath the top toward the front, and disconnecting lid switch, or i found it easier to just unscrew and remove it, then lift off the top/lid assembly. Remove the agitator cap and the agitator. Remove the splash cover (this is not easy- I popped each tab with a flat screw driver- the ones at the rear were very difficult). I tried to remove the fill spigot but could not get at one of the screws so getting the splash cover out was not as easy as it could have been. Remove the bolts in the bottom of the tub and lift it out. Unhook the drain hose and the level or "pressure tube". Remove the 3 large and 3 small springs from the motor assembly ( I needed a strong spring hook but all I had was vice grips, they work but it was not easy). remove any other wires etc. (mark things with tape and matching numbers if needed) and pull out the whole barrel and motor assembly. Unbolt the splash tub and remove, unbolt the trunnion and remove. And finally replace the seal. Reassemble in reverse order. Important!! Clean shaft well (I used some 300 grit fine sandpaper to remove the little bit of rust scale that had accumulated) and lubricate everything. be very careful when reassembling, as to not scuff up the seals at all. I used a silicone spray. This might not be the best thing for the job but I know at least not to use anything petroleum based such as WD-40 when you are lubricating rubber or plastic. Reinstalling the springs was very difficult and again a spring hook would have been great. Everything else went together reasonably easy. The unit works fine now. many thanks to the websites I researched to get this done.

Parts Used:

-

Michael from Springfield, VT

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Pliers, Screw drivers, Socket set

29 of 35 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The washer would not drain

After removing the front of the washer, I used slip joint pliers for the hose clamps, then a screwdriver for the mount bolts and replaced the pump motor in reverse order. The pump was ordered on line on a Friday before 10am and was delivered on saturday moring by FedEx. I could not have expected such fast and efficent service!

Great Job!!

Great Job!!

Parts Used:

-

Harry from Zephyrhills, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

24 of 24 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

discharge of water out of wash machine

remove side panel & start rinse cycle & heard a grinding noise in discharge pump. used a bucket to catch water upon removeal of discharge hose to pump. unplug disconnect plug to motor, remove pump from unit. Discovered propeller was loose in housing. Googled Partselect.com, odered part & in 2 days later installed new pump on unit. Started a load of wash & it has been working perfect ever since. thanks to PartSelect.com for the service, the repair was minimal & easy for the DO IT YOURSELFER. Bill Starry

Parts Used:

-

William from York Springs, PA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Pliers

26 of 33 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Water not draining

It turned out that the pump was fine. There is a filter within the rubber bellows between the washer drum and the motor. You need to remove the entire bellows to get to it. Just remove the motor and you can un-clip the hose tensioners. They are exactly like the ones you would fine on most foreign cars - just compress with pliers and move back on the hose. Clean out the plastic filter. A small nail had worked its way through the plastic filter and lodged in the motor impeller. Removing this nail and reassembling, it all worked as new! I kept the pump and motor as a future spare rather than return it.

Parts Used:

-

Harold from Denver, NC

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers

22 of 24 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

water pump broke

My Husband did the repair it took less than 15 minutes. He popped the front off the washer. He then unscrewed two screws and removed the pump assembly. He popped the new pump in, and put in the tow screws. Then he put the washer front back on replacing two screws. It took all of five minutes. I am so pleased it was so easy. I told him next time I'd do the repair and he could watch!

Lil

Lil

Parts Used:

-

Lili from Jamestwn, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

22 of 24 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!