GCG950-02 General Electric Trash Compactor - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Compactor Piston stays down even though the motor is running

If the drawer is stuck because the piston is in it, you will have to take the back off to lift the piston in order to remove the drawer.

With the drawer out, tip the compactor on its back to easily maneuver the otherwise heavy piston. Working from the front remove the trunnion nut cover (two hex screws) and then the bad trunnion. You may need to move the front of the piston up or down to release the nut.

Remove all the debris and wipe the shaft from old grease and debris.

Grease the shaft with supplied grease. With the piston about 1/3 of the way down, screw the new trunnion nut until it touches the housing. Move the front of the piston up or down to seat the nut. Put the nut cover back on and screw it in position.

The whole job took less than 30 minutes.

With the drawer out, tip the compactor on its back to easily maneuver the otherwise heavy piston. Working from the front remove the trunnion nut cover (two hex screws) and then the bad trunnion. You may need to move the front of the piston up or down to release the nut.

Remove all the debris and wipe the shaft from old grease and debris.

Grease the shaft with supplied grease. With the piston about 1/3 of the way down, screw the new trunnion nut until it touches the housing. Move the front of the piston up or down to seat the nut. Put the nut cover back on and screw it in position.

The whole job took less than 30 minutes.

Parts Used:

-

Robert from San Deigo, CA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver

16 of 20 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Plastic trunnion nut was worn out

The problem with this repair arises after you have removed the old trunion nut and you are trying to get the new one to seat into the narrow bracket that surrounds it and keeps it from turning. You can only screw the trunion nut on so far and then it runs into the edges of the bracket. I found that by aligning the new trunion nut at the proper angle and then jacking the compacting ram up a few inches with an automotive jack from the car, the trunion nut is forced into place and then you can put the facing bracket back on and you are done.

Parts Used:

-

Joe from Avondale, AZ

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers, Socket set

10 of 12 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The ram would not raise and the motor kept running.

I actually pulled the entire motorized unit out of the case, not knowing what the problem was. I found that the old nylon trunnion nut was stripped. I ordered two replacement trunnion nuts in case the replacement stripped out also. (However, the manufacturer has replaced the old nylon nut with a threaded metal unit that should never strip so I goofed when I ordered 2. )

I removed the nut retainer, cleaned off the main drive screw, applied the supplied grease to the drive screw and the new trunnion nut and then reassembled the compactor. In actuality I didn't need to remove the entire power unit and would have only needed to remove the back panel of the compactor to reach the nut retainer.

I removed the nut retainer, cleaned off the main drive screw, applied the supplied grease to the drive screw and the new trunnion nut and then reassembled the compactor. In actuality I didn't need to remove the entire power unit and would have only needed to remove the back panel of the compactor to reach the nut retainer.

Parts Used:

-

Scott from Colleyville, TX

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers, Socket set

6 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

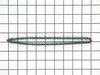

Ram was stuck in the down position, would not return up.

1.I removed the back of the compactor

2. turned the large nut to raise the ram so I could remove the trash container

3. removed the bolt holding ram plunger onto the actuator

4. put the chain on by starting it on the large sproket and walking it around. there was enough slack to do it this way.

5. cleaned and oiled everything and reassembled.

2. turned the large nut to raise the ram so I could remove the trash container

3. removed the bolt holding ram plunger onto the actuator

4. put the chain on by starting it on the large sproket and walking it around. there was enough slack to do it this way.

5. cleaned and oiled everything and reassembled.

Parts Used:

-

Ian from Camano Island, WA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Socket set

4 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Cheap original plastic trunnion nut broke.

Removed broken plastic tunion nut and replaced with new aluminum die cast trunnion nut.

Parts Used:

-

Kenneth from Felton, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Compactor would not return to parked position

The big problem was how to get to the drive since the ram was down in the compression stage. I was able to remove the two door hinge pins and with a bit of prying and movement was able to disengage the door lock and totally remove the door. That removal disclosed the broken nylon trunion nut. After digging out all of the compressed trash, I used a small car jack to raise the ram slightly and remove the nut holder and broken nut. In replacing the nut, I had to decide at what point in the ram travel to install the new nut. Realizing that at full compression the nut would be fully taken up on the screw, I raised the ram perhaps 1/4 to 1/2 inch to allow for play, and after greasing the screw well, tightened the nut all the way against the nut mount, and replaced the nut holder. After several test runs, I replaced the door. It works now. Note- the original nut was nylon which stripped and split. The replacment was metal, which should be better.

Parts Used:

-

Monte from Estes Park, CO

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set

2 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Stripped trunnion nut

Considering this was the 4 trunnion nut (1 nylon and 2 metal) I have replaced - I am getting pretty good at fixing this lowley, poorly manufactured, poorly designed piece. I have replaced 2 transmission boxes and replaced the chain as well. I have had several great experiences with partselect.com - they are set up as a favorite in my web browser for a few reasons, great price, great delivery

Parts Used:

-

Mark from Campbell, CA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

2 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Trunnion gear stripped, compactor would not rise.

There are two threaded nuts that hold a shield around the trunnion gear. These must be removed and the stripped gear can be removed. Here was the key for me. The new Trunnion gear cannot be spun into place where it is flush to the scissor gear because the screw is not threaded completely, this is by design.

After the trunnion gear is spun on as far as possible, you must lift the extended compactor head/scissor gear enough to move the trunnion gear flush against the body of the scissor gear. This is the only way to replace the cover over the trunnion gear. replace the threaded nuts, and the job is finished.

Don't forget to lubricate the gear/screw.

After the trunnion gear is spun on as far as possible, you must lift the extended compactor head/scissor gear enough to move the trunnion gear flush against the body of the scissor gear. This is the only way to replace the cover over the trunnion gear. replace the threaded nuts, and the job is finished.

Don't forget to lubricate the gear/screw.

Parts Used:

-

Christopher from Lemont, IL

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The plastic trnnion stripped out

Removed the trunnion hold down bracket using 5/16 nut driver. Slid strpped trunnion off screw shaft. Washed screw shaft with low odor mineral spirits to remove old grease. Applied grease supplied with order to threads in new trunnion and screw shaft. Screwed trunnion onto screw shaft until it reached trunnion housing. Aligned trunnion with trunnion housing and then turned screw shaft counter-clockwise until trunnion was seated. Replaced hold down bracket and that was it!

Parts Used:

-

Paul from Southlake, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver

1 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Trunnion Nut Stripped out

I laid the compactor on it's back, so the weight would not slid to the full extend position. Removed the two screws with a nut driver and removed the old trunion nut. I installed the new nut and installed the retainer. Then set the compactor in the upright position. I inserted a screwdriver in the safety switch. pluged in the unit,and ops checked the new part. All worked well. The new Trunnion nut was made out of metal, and should last longer. I recived the part in about 3 days. That was fast and the correct part was delivered. Thanks to the folks at PartSelect.

Parts Used:

-

Terry from Cordova, SC

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

Was this instruction helpful to you?

Thank you for voting!

Bolt holding Ram Backed out and stripped, which allowed Ram to drop offline and wedge and bind in down position.

I am handy, but this repair was beyond my abilities. I called an appliance repair company whom I had not used before. They were recommended by the local appliance repair parts store. The repairman was able to get the Ram unwedged and back in position in the up position, but I was told by the parts store, that he could no longer get the bolt and nut we needed to complete the repair. I went on line, and found PartSelect. I was told that the parts were available, but it would take a couple of weeks to get them, and then they would ship them to me. We got the correct parts, a specialized bolt and nut. The repair was completed today at a very reasonable price. If this repair could not have been possible, we would have needed to change compactors and rework our kitchen cabinet, both at great expense. We are very happy with the service we recieved from PartSelect. Thank you very much.

Parts Used:

-

Elbert from Simi Valley, CA

-

Difficulty Level:Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Socket set, Wrench (Adjustable), Wrench set

Was this instruction helpful to you?

Thank you for voting!