2375 - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

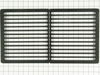

replaced filter

-

ELOISE from MILFORD, OH

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

482 of 504 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Old grease filter that I actually did not know I had to change

Removed the old grease screen and cleaned the entire area thoroughly and replaced the screen

Parts Used:

-

deborah from fort pierce, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

448 of 534 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

My Jenn-Air is an "antique." The filter was disgusting!

I had put up with a filter that got more and more raggedy every year, but I thought my 30 yr. old range/grill top was too old for me to find an replacement filter. What a great service you offer. I found you by web-surfing, typed in the model #, and presto--you sent me the shiny new filter. All I had to do was pop it in and throw away the nasty grill (after washing the scent off to keep the bears out of my Colorado garbage.) Thank you!

Parts Used:

-

marion from aspen, CO

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

166 of 319 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Deterioration of fuel line system

Removed the top cover (T25 torx), and side cover (T25 torx) with recoil starter. Drained all fuel, and removed all pieces of fuel old fuel line and the weighted filter from inside the tank by shaking out and the (long forceps). A spot headlamp makes it easier to see inside the tank for much of the procedure. Remove the foam filter to find the two 8mm nuts and remove the air filter housing and carburetor (nut driver, 8mm socket) the choke lever slides out of its slot with some wiggling and moving the carb back off the mounting studs. Leave the throttle cable attached to the filter housing and move both assemblies out of the way to access the top wall of the fuel tank. There is a cover over the carb adjust screws that wiggles out also. The fuel line and purge line both pass through the wall of the tank and need to be pulled out with some effort (long curved forceps) from inside the tank through the fuel fill port. They are a tight fit. Pay attention to the lines size and location. Large line is in the position away from the recoil starter with the little plastic fitting hanging near the top of the tank. The smaller line is closest to the recoil starter. Both new lines will need to pass through the tank wall (this is the most difficult part). To facilitate the initial entry through the wall of the tank, cut a tapered end on your new lines. Use a very slippery lube to coat the end of the line and push it into the tank as far as you can from the top (forceps or soft grip pliers) help. Look inside the tank and pull the lines through fully out of the tank fill (long curved forceps and head spot light). Don't pull all the way through the fuel fill, just enough to install the new fuel line fitting in the return purge line and the new weighted filter on the fuel line and pull the lines back inside the tank. The return line with fitting close to the top of the tank and the filter hanging so it lays at the bottom of the tank, and able to swing around so it keeps contact with fuel at all times. Remove the old purge/primer bulb two screws (Phillips). The short stem is suction, long stem is pressure. Don't mix them up and connect lines backwards, don't ask me how I know! Lol! If you have such a saw like mine, that has no fuel lines intact, it is difficult to vision the line routes. There are helpful schematics on the internet. Just remember that the purge bulb long fuel stem sends pressure back to the tank through the return line (larger line in the tank with the line fitting away from the recoil). That line can now be cut to length and pushed on the bulb long stem. The suction side of the bulb short stem, connects to the purge line on the side of the carburetor (short line). You need to cut that line to the same length as the old one. It has to curve twice to get to the suction side of the purge bulb without kinking. The only other line left is the fuel line with the filter attached hanging inside the tank. Be sure you have the filter able to lay on the floor of the tank and move around. That line connects to the carburetor opposit side from the purge bulb. Dont cut that one until the carb is installed for proper length. The fuel routes from that filtered line into the carb, then out of the carb to the purge bulb suction side, then out to the return line in the tank with the fitting end. That fitting installed into the line serves only to keep the line from pulling back out of the tank, nothing attaches to it. Make sure all lines are clear of the mounting area of the carb, and throttle function. Pass the bulb lines through the slot in the side of the case being sure the lines don't kink. Secure the bulb with the two phillips screws. Position the carb on the studs and slide the choke lever into its place in the case as you go. Place the filter housing on the studs and push the carb and housing down watching the fuel lines for any kinks, especially where the throttle cable is in close proximity to the short carb purge line. Check the throttle function for interferance, and Install the two 8mm nuts. Now route the fuel line around the throttle mechanism out of the way, hold it to the barb on the side of the carb and cut it to length and install. Put some fuel mix in the tank (dont fill it) to test. Press the primer bulb, tilting the saw with fill cap removed, and see if anything leaks, also watch fuel flow back to the tank inside as you press the bulb. You should see fuel and air bubbles from the purge line. When all air bubbles are gone the system is purged. Install the new foam filter in the housing and then the top and side cases. I did not reinstall the cover of the carb adjust needle screws so I could adjust the fuel/ air mixture to run at peak performance. Hope this helps! The kit that I got was perfect and there are some useful instructions included. Thank you! Respectfully Mark

Parts Used:

-

Mark from LYNDONVILLE, NY

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set

92 of 100 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Falling apart 20 year old grease filter for downdraft counter rangetop

Cleaned out the downdraft cove, inserted the new filter, and put old filter in garbage can. Laughing. Thanks. Wish you had a FAQ's hotline. I'd like to know if the radiant inserts fit the older coil-type models.

Parts Used:

-

Roe from Raleigh, NC

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

147 of 289 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Burner had no temperature control other that full on.

Locate and open appropriate breaker to kill power to the range. (very important if you intend to see tomorrow).

Pull off the control knob.

Remove 2 screws that hold in control pannel.

Lift out the control pannel to the extent that the wires will let you. (2-3 inches)

Remove the nut that holds the switch/controller in the pannel.

Remove the wires one at a time and reconnect them to the new switch. Make sure to connect them the same way on the new switch.

Re-install the switch in the pannel.

Re-install the pannel in the stove.

Close breaker and test burner contol.

Pull off the control knob.

Remove 2 screws that hold in control pannel.

Lift out the control pannel to the extent that the wires will let you. (2-3 inches)

Remove the nut that holds the switch/controller in the pannel.

Remove the wires one at a time and reconnect them to the new switch. Make sure to connect them the same way on the new switch.

Re-install the switch in the pannel.

Re-install the pannel in the stove.

Close breaker and test burner contol.

Parts Used:

-

Eric from North Andover, MA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

62 of 71 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Both the Fuel line and the Engine fuel line, where dry rotted.

1) While still attached to the fuel tank, I first sized up the old fuel lines with the newer fuel lines.

2) With a pair of needle nose players, I then removed the old dry rotted fuel ?? lines, from the fuel tank.

3) I cleaned the fuel tank and around the carburetor area, to insure that there was no debris, that could possibly fall into the path of the new fuel lines installation.

4) I then installed the smaller one of the fuel lines, so that it would be out of the way, of the larger fuel line. I Pulled the fuel line through the smaller hole in the fuel tank, with needle nose players. I pulled the smaller fuel line out through the fuel tank filler hole, attached the fuel filter to the smaller fuel line. I Made sure that the fuel filter was extended to the furthest end of the fuel tank bottom. Six inches in all. I then attached the smaller fuel line to the carburetor.

5) I Installed the larger fuel line, followed the same procedures as the smaller fuel line.

6) Both fuel lines where cut on an angle for easy installation. No lubricant was necessary.

7) I filled up the fuel tank with fresh fuel and oil, new air filter and spark plug. It started on the first pull. Amazing.

2) With a pair of needle nose players, I then removed the old dry rotted fuel ?? lines, from the fuel tank.

3) I cleaned the fuel tank and around the carburetor area, to insure that there was no debris, that could possibly fall into the path of the new fuel lines installation.

4) I then installed the smaller one of the fuel lines, so that it would be out of the way, of the larger fuel line. I Pulled the fuel line through the smaller hole in the fuel tank, with needle nose players. I pulled the smaller fuel line out through the fuel tank filler hole, attached the fuel filter to the smaller fuel line. I Made sure that the fuel filter was extended to the furthest end of the fuel tank bottom. Six inches in all. I then attached the smaller fuel line to the carburetor.

5) I Installed the larger fuel line, followed the same procedures as the smaller fuel line.

6) Both fuel lines where cut on an angle for easy installation. No lubricant was necessary.

7) I filled up the fuel tank with fresh fuel and oil, new air filter and spark plug. It started on the first pull. Amazing.

Parts Used:

-

Victor from SCOTTSVILLE, KY

-

Difficulty Level:Very Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Socket set

29 of 37 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Lettering on old stove knobs was no longer visible and knobs were loose.

-

Chris from Poway, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

26 of 31 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Just ugly this time`

It's wonderful to get accessories for this 20 year old Jenn-Air. I love it and now it looks like new.

Parts Used:

-

Susan from Chino, AL

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

22 of 24 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Old Jenn--Air cook top inop. Model discontinued

Our Jenn-Air cook top is 25 years old. One can no longer order parts for this old of model. We ordered new SS burners as well as new Burner cartridge terminal blocks for a new and current model. They work perfectly. Took 10 minutes. $ 350 dollars verses $ 2600 for a new JennAir range plus instillation. Unit looks and works great. Plan to order new switches next.

Parts Used:

-

Ronald from Avon, CO

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

20 of 27 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Fuel and Purge lines had disintegrated

Disassembled it and cleaned fuel tank. Cut and ran new fuel lines, installed filter and reassembled. Parts fit perfectly and got running after not running for over 20 years.

Parts Used:

-

Casper from ERATH, LA

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers

18 of 25 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

missing screws for oven door

After searching on the internet for a very long time, we were almost ready to order the screws "blind" (no picture) from Sears for almost $10.oo per screw. Then I stumbled onto this website and found exactly what I was looking for, with a detailed description AND a picture!! Not to mention a price that was two thirds less than Sears..for TWO screws. Now the oven door is secure and we are no longer on our search for the right screws.

Parts Used:

-

donna from baltimore, MD

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

13 of 15 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

bad element control switch

1. Turn off power to range at circuit breaker

2. Remove grate

3 Remove control knobs

4, Remove two screws holding control panel

5. With wrench, remove locking nuts from control switches

6. Lift panel, exposing switches

7. With new switch in hand, unattach old switch one terminal at a time, attaching new switch exactly as old switch, terminal by terminal.

8. Replace everything in reverse order

9.Turn on power

2. Remove grate

3 Remove control knobs

4, Remove two screws holding control panel

5. With wrench, remove locking nuts from control switches

6. Lift panel, exposing switches

7. With new switch in hand, unattach old switch one terminal at a time, attaching new switch exactly as old switch, terminal by terminal.

8. Replace everything in reverse order

9.Turn on power

Parts Used:

-

Richard from Beverly Hills, CA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers, Wrench set

11 of 15 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Old switch had burned out and needed to be replaced

Turned off electricity at the circuit box. Removed four screws from panel cover that housed the switch. disconected the wires from the old switch and replaced the old switch with the new one reconected the wires put the panel cover back on. voila done.

Parts Used:

-

Jeannine from Twentynine Palms, CA

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

9 of 9 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

knobs were old could not read numbers

-

catherine from holland, MA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

8 of 10 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!