PDW7880J10SS General Electric Dishwasher - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Original Silverware Basket Broken

Removed original silverware basket from dishwasher rack. Replaced it with new silverware basket. Placed original silverware basket in recycle bin (plastic content). So easy, even my 24 year old son could do it!

Parts Used:

-

Craig from Cedar Rapids, IA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

10 of 15 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

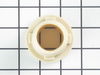

dishwasher check valve

No Plumer could help me. No one heard of a dishwasher check valve. My dishwasher was an ISA. I was lost until i found the relationship to Kitchenaid. Then sears. Vuela!

The valve was there, but unavailable.

A few more links, and the term "flapper" came up.

Well, my dishwasher check valve HAD a flapper inside. Although a plastic pos, i could unscrew the two halves and see the flapper.

A little piece of rubber, about 1" in diameter

All suppliers gave me but two choices. One large (size given) one smaller.

After years of searching, all I needed was a flapper valve. Not the whole check valve.

I found it hear for under $10

The valve was there, but unavailable.

A few more links, and the term "flapper" came up.

Well, my dishwasher check valve HAD a flapper inside. Although a plastic pos, i could unscrew the two halves and see the flapper.

A little piece of rubber, about 1" in diameter

All suppliers gave me but two choices. One large (size given) one smaller.

After years of searching, all I needed was a flapper valve. Not the whole check valve.

I found it hear for under $10

Parts Used:

-

ted from columbia, SC

-

Difficulty Level:Very Difficult

-

Total Repair Time:Less than 15 mins

7 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Very, very easy. Took about 5 minutes. The end cap was on and working. And the repair company would charge $65 just to come out and look at it. It costs $9.00 to fix it. I am moving on to the refrigerator next. Very satisfied. Shipping is well worth the money. Ray D, Ansonia, CT

Old cap was already off and had string on it. Cut the string. Placed end cap over. Used needle nose pliers to open metal rail a little and put in new cap. Locked right in. That was easy. Thanks again.

Parts Used:

-

Raymond from ansonia, CT

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers

8 of 10 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Latch to pop up door to soap dispenser broken.

I took the front off of the dishwasher door, loosened the screws, unplugged the module and replaced it with the new module. This repair was the easiest repair I've ever completed!

Parts Used:

-

Jonathan from Nashville, TN

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

8 of 11 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Gasket missing from factory, caused dishwasher leak when ran.

Took off old funnel fill and put in funnel fill gasket and new funnel fill just to have a new one.

Parts Used:

-

Jennifer from San Antonio, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

12 of 24 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Lower spray arm falling apart, dishes not cleaned

This was very easy. 1) roll out lower rack, 2) rotate lower arm slightly counter-clockwise and lift it out, 3) install new lower arm by dropping into position and rotating clockwise. 4) roll in lower rack, and roll out upper rack, 5) use a nut driver to remove the retaining bolt/screw from the upper arm - it's in the center of the upper arm and you have to work from underside of upper rack, 6) remover upper arm, 7) install new upper arm by holding in position and re-inserting the retaining bolt/screw. 8) Tighten the retaining screw and make sure upper arm freely rotates.

Parts Used:

-

David from Lincoln University, PA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver

7 of 10 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dishwasher wouldn't drain completely

Removed the dishwasher from the cabinet. Turned it on it's top side. Removed the exit hose from the pump with a nut driver and replaced the flapper. Reconnected the hose to the pump.

Parts Used:

-

William from Nacogdoches, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Wrench set

7 of 10 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Door Latch Broke

This isn't a terribly tricky repair, and the parts are cheap so it's worth a try!

(I had one tricky thing which was the door actuator broke while the door was shut. So I had to get the machine out of it's space without being able to open the front of the machine. I did this by lowering the feet in the front of the machine and then I used a hammer and flat chisel to break the two metal screws I had holding the top of the machine to the top of counter top...a little tricky!)

Remove screws from inside lower panel (where you put soap..the bottom) this will allow you to remove the inside of the door. But be careful as there are still wires attached so be careful to place the inside part without stressing the wires.

I needed to remove the metal harness and to open the black rectangular box that holds the interlock plunger so I could remove the plunger and spring (don't lose..and remember how it goes. take pictures if necessary). Then I was able to remove the broken actuator and see how it all fits together. It rests on top of the latch with notched side facing the inside of the machine. Make sure the notch is centered around where the interlock plunger is located.

Once you have the pieces fit together insert them into the door. Replace the plunger and spring and close the black rectangular box. Then replace the metal harness.

Hold everything in place and put the inside of the door back into position and lock it down with the screws.

You can test the door to make sure it's working but the whole mechanism is less functional when the machine isn't secured into its space. So, if you're mostly sure you've got it right, resecure the machine into its space making sure it's solid and then you should be good.

Like most everyone here I was very happy to accomplish this repair without calling in the repair service!! Awesome.

(I had one tricky thing which was the door actuator broke while the door was shut. So I had to get the machine out of it's space without being able to open the front of the machine. I did this by lowering the feet in the front of the machine and then I used a hammer and flat chisel to break the two metal screws I had holding the top of the machine to the top of counter top...a little tricky!)

Remove screws from inside lower panel (where you put soap..the bottom) this will allow you to remove the inside of the door. But be careful as there are still wires attached so be careful to place the inside part without stressing the wires.

I needed to remove the metal harness and to open the black rectangular box that holds the interlock plunger so I could remove the plunger and spring (don't lose..and remember how it goes. take pictures if necessary). Then I was able to remove the broken actuator and see how it all fits together. It rests on top of the latch with notched side facing the inside of the machine. Make sure the notch is centered around where the interlock plunger is located.

Once you have the pieces fit together insert them into the door. Replace the plunger and spring and close the black rectangular box. Then replace the metal harness.

Hold everything in place and put the inside of the door back into position and lock it down with the screws.

You can test the door to make sure it's working but the whole mechanism is less functional when the machine isn't secured into its space. So, if you're mostly sure you've got it right, resecure the machine into its space making sure it's solid and then you should be good.

Like most everyone here I was very happy to accomplish this repair without calling in the repair service!! Awesome.

Parts Used:

-

Erik from New York, NY

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers, Wrench (Adjustable)

7 of 10 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

White latch on soap dispenser broken- would not latch

The first posted instruction is dead on (except there are 14 phillips screws (not 10) on inside of door. Also, when reconnecting the 2" quick connect, make sure it is fully inserted - otherwise the numbers on the display panel will not show correctly. Mine didn't the first time, and I had to re-open the door panel and giggle around with the connection to get the numbers to display properly.

Parts Used:

-

David from Stamford, CT

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

6 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Water leak from under dishwasher. Leaky inlet sump

Disconnected the electricity, the drain hose, and the water supply from the dishwasher. Loosened the two screws from the countertop and pulled out the dishwasher. Turned it on to it's side. Saw the damaged inlet sump. Had to remove the Pump connector to get to the inlet sump. Checked it also and discovered that it was starting to develop a small crack from the inside. I decided to replace it as well. The job involves removing the hose clamps and removing the spray mechanizm from the interior of the dishwasher to spin out the inlet sump. Not a difficult job.

Parts Used:

-

SAMUEL from DUNCANNON, PA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers, Wrench (Adjustable)

9 of 17 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dishes did not get clean

I watched the video, read the instructions and went to work. This was the easiest repair I have ever done. I'm 71 and if I can do all 3 spray arms in a total of 15 minutes, anyone can. The hardest part was getting up off the floor when I was finished. The spray arms were all clogged, we have very hard water.

Parts Used:

-

Dennis from ELOY, AZ

-

Difficulty Level:Very Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Wrench set

5 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Pump Connector Leaking

Open dishwasher and remove the bottom spray wheel, filter, and unscrew the mounting bracket to release the pump connector below the bottom of the unit. Remove mounting screws at top front of dishwasher and carefully slide the unit out; you may have to pry side panels inward with a flat screwdriver in order to get the dishwasher past any cabinetry. Be careful not to pull the dishwasher too far out as the water supply and drain hoses could be damaged. Unplug the unit. Turn unit sideways and tip over onto its' back. At this point, the sump will have to be removed using a nut-driver and/or socket set. This will open access to remove the old pump connector. Replace the old connector with the new connector, and reassemble the sump, connecting and firmly tightening all connectors. Tip unit upright. Screw mounting bracket back into the bottom of the dishwasher and put the remaining parts back. Before pushing the unit back into it's nook, I advise running a quick cycle just to make sure there is no leakage. If there is no leakage, put the unit back, tighten the mounting screws and you're done.

Parts Used:

-

Jim K from Whittier, CA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers, Wrench (Adjustable)

6 of 9 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

clunking sound every second when lower spray rotating

get fingers between lower spray arm and drive flange - rotate arm counter-clock wise and lift off...the arm was warped and hitting inside of lower door liner.

Parts Used:

-

D F from Estes Park, CO

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

7 of 12 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

old part leaked

unscrewed dishwasher from cabinet, then I flipped dishwasher on it's side. loosen pump motor bracket arm on the end of the motor. loosen pump motor to pump conecter hose clamp and then unscrewed pump motor connector from dishwasher. To install I did the reverse. very easy.

Parts Used:

-

robert from east windsor, CT

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers, Wrench (Adjustable)

4 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The rack wheels and axles on the DW had broken, causing the upper rack to come flying out when opened.

Took the rack out. Took off the broken wheels and axles. Popped the new ones on, while replacing the rack. Piece of cake! Saved over $100.

Parts Used:

-

Nancy from Big Rock, IL

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

4 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!