A206 Maytag Washer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

No cold water -- only hot

My washing machine would only run hot water. Told my husband and we were ready to call the repair man when I suggested we try to order a part. So I Googled "washing machine repair". Clicked on the first sight I saw and 'searched 'no cold water' amd immediately saw explanation of our exact problem. The solution explained that MOST of the time the problem was the water inlet valve. So I ordered the part. My husband put the part on the machine and the process would have taken less than 10 minutes however the clamp was so rusted to broke and that required a trip to the hardware store. But I suppose clamp-life does not exceed 20 years. So mission accomplished and a great big thanks to all those who explained what they did to solve the problem!

Parts Used:

-

Darla from Loves Park, IL

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers, Screw drivers, Socket set

4 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer leaking water

After figuring out how to open the washer I could not find where the leaking water had come from. I ran the washer without the front cover (cold water) and it didn't leak. When I finally accidentally blocked the intake on the tub did it squirt out inside the washer. It turned out that it would only leak with both hot and cold water combined was the pressure big enough to leak. The place it leaked was about halfway between the intake valve and where it entered the tub in what looked like a small plastic housing with slots. The functionality of this thing is still in question. I call it the Kazoo because it makes noise so you can tell the water is going in. I can see that it also holds back pressure so the washer does not fill too fast if the incoming pressure is too high, but I have my doubts about this. It turns out the intake hose is interrupted with by a jet inside a 3 inch black rubber tube (valve) that extends into the second hose. The water pressure expands the rubber (valve)and makes noise. The way I see it old rubber had maybe shrunk and lost its ability to resist pressure so it overflowed because too much water was coming through. The new piece I ordered was 3/8 inch longer then the one that came out. Maybe a planned obsolence part. (My wife wanted to buy a new washer and dryer at the first sign of trouble.) Anyway the repair was pretty simple. No clamps needed the old one is easy to undo and you just replace the kazoo. By the way while I was waiting on the parts to get here I just throttled the water pressure on the wall so it wouldn't leak. On this maytag washer you take off the screws on the front towards the bottom to start. I did not notice them untill I had damn destroyed the lid. After you remove the front cover there are 2 screws in the top front corners to remove and the the top pops off. They repair is easy understanding it took some thinking. Good luck.

Parts Used:

-

Prosper J from Gretna, NE

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Screw drivers, Socket set

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer would not run

There are two screws that hold the switch in place. And two wires connected to the switch. The most difficult part of replacement is to place the new switch and hold it in place to reinstall the mounting screws. The space to work in is limited unless you remove the front panel from the dryer, which I opted not to do.

Parts Used:

-

james from york, PA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Pliers, Screw drivers

4 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Cold water barely coming in.

First thing I had to determine what was wrong. The machine had worked admirably for a 1980 model but over the last few years cold water input had reduced to almost nothing. There was also a slight hum during filling but it had been so gradual I really didn't recognize it as part of the problem.

After checking that the cold water faucet, hose and screens were okay I removed the front panel to see how water flowed inside the machine. I suspected the inlet valve on the machine was not working correctly so I looked on PartsSelect and found similar repair stories. I ordered one and it arrived in 2 days.

Repair was simple. Turn off hot and cold water and disconnect hoses from machine. Mine were on snug so it took pliers to get a turn started. Lay them in a pan to catch drippings. On the back remove the single nut above the inlet valve and lift to remove the panel. Remove the two mounting screws for the inlet valve. If needed rotate the electrical connections on the new inlet valve to match the old and transfer the wires. Remove the small output waterline and transfer it to the new valve. Mount the new valve to the panel and resecure the panel to the machine. Snugly attach the hot and cold water lines. Turn on the water and after checking for leaks you're good to go.

After checking that the cold water faucet, hose and screens were okay I removed the front panel to see how water flowed inside the machine. I suspected the inlet valve on the machine was not working correctly so I looked on PartsSelect and found similar repair stories. I ordered one and it arrived in 2 days.

Repair was simple. Turn off hot and cold water and disconnect hoses from machine. Mine were on snug so it took pliers to get a turn started. Lay them in a pan to catch drippings. On the back remove the single nut above the inlet valve and lift to remove the panel. Remove the two mounting screws for the inlet valve. If needed rotate the electrical connections on the new inlet valve to match the old and transfer the wires. Remove the small output waterline and transfer it to the new valve. Mount the new valve to the panel and resecure the panel to the machine. Snugly attach the hot and cold water lines. Turn on the water and after checking for leaks you're good to go.

Parts Used:

-

Kathy from Priest River, ID

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers, Socket set

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The washing machine ran noisily

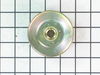

Remove the power cord and water hoses. Lay the machine on the floor. Remove two belts (washing and pumping). Unlock the screw of pulley using a hex key. Remove the broken pulley from the motor. Place in the new pulley. Lock the screw of the pulley. Install two belts. Turn the machine vertically. Plug in water hoses and power cord. Level the machine.

Parts Used:

-

Xuanbao from Norwalk, CA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

5 of 9 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

agitator did not move, all other functions OK

Removed the bottom belts to inspect. Belt for tub was well beyond it's service life. Belt for pump was OK. ordered the pair and replaced. When the washer was started the agitator still did not move. With power off I grabbed the agitator and pulled upward a few times then twisted it from side to side a few times. No change. Then I did the same with it with powered up ( a bit dangerous ). The agitator then ran OK.

Parts Used:

-

nicholas from white plains, NY

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:15 - 30 mins

4 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

broken belt

Layed the machine on it'sback and put the 2 belts on the pulleys,Very easy ,when you know to put the machine on it's backside!

Parts Used:

-

Ray from Cool, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

4 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Slow fill cycle - Hot water barely ran into tub during fill

First I unplugged the power cord from the wall. Then I turned off the water supply shut-offs at the wall and removed the hot & cold connections at the rear of the washer. Then I removed the two screws that held the assembly in the rear of the washer. I then pulled the assembly out about 3-inches, marked the new assembly to show the proper color of wire for each lug and disconnected the four wires at the lugs. I disconnected the rubber fill hose from the assembly and removed the assembly. Next, I installed the new assembly in the reverse order. It worked fine without any leaks & saved me from buying a new washer. My old washer now gets my clothes cleaner than it has for years - much quieter and quicker too.

Parts Used:

-

Charles from Thousand Oaks, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver, Pliers, Screw drivers

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washing machine leaked when filling

After removing the front cover and tilting up the top of the washer housing, the area of leakage was obvious. I unscrewed the clear plastic injector housing, loosened the clamp, slid the hose off of the clear plastic injector housing, and removed the plastic injector nozzle and the rubber injector valve.

I then order the plastic injector nozzle and the rubber injector valve. After the parts arrived, I simply put things back together, and no more leak!

Note: When putting the plastic injector nozzle into the rubber injector valve, I used a little liquid detergent as a lube.

I then order the plastic injector nozzle and the rubber injector valve. After the parts arrived, I simply put things back together, and no more leak!

Note: When putting the plastic injector nozzle into the rubber injector valve, I used a little liquid detergent as a lube.

Parts Used:

-

Mark from Yorktown, VA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Socket set

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

pump and drive belt was thorn

Installed drive and pump belt.. very very simple. only tool required was a screw drive to remove front panel of the washing machine.

Parts Used:

-

Henry from KITTERY, ME

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

4 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

burning smell from washer

Replaced both the drive belt and pump belt in less than 10 minutes. Maytag has the easiest machines to work on.

Parts Used:

-

kevin from mundelein, IL

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

4 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Agitator was not agitating. Thought it was stretched/worn belt. It was not! Transmission is shot!

Could not repair. The gearbox on the agitator was broken and that kept the agitator from working. Do not assume it is a belt problem on a washer built in 1987.

Parts Used:

-

Norman from LAKE ZURICH, IL

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Letting to much water in.

Turn water off, removed water hoses. removed plug from elec. outlet.Then remove water inlet valve.very simple.

Parts Used:

-

Harold from CLERMONT, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Pliers

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

old belts slipping squealing, rubber shavings on floor.

Pull washer out from wall. Remove front panel (2 Philips head screws), swing bottom of panel out, remove panel. Tilt washer backwards, lean against wall to expose area under washer. Roll off old belts, roll on new belts. Move washer back upright, replace front panel, replace the philips screws, move washer back to original position.

Parts Used:

-

Elzo from KALAMAZOO, MI

-

Difficulty Level:Very Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washing machine was making a weird churning sound during the wash cycle and was slowly leaking water from bottom.

I followed the instructions on this website to a T. You can take the front cover off and you will notice a small drip from the tub area where the Hub bearings (above the tranny) meets the washing tub. Once you've identified that the leak is indeed coming from that area and not a loose tube. Allow the washer to complete the job and drain the water. Then simply unplug washing machine before starting the process of the repair. It is very important to remember that you must have a spanner wrench before attempting to perform this repair. keywords=spanner+wrench came within two days with Prime Shipping. Also be sure to order the replacement parts from this site. It takes about 3 days to arrive however so be prepared to be without a washer for a few days. Other than that just follow the instructions provided and there is a very good step-by-step video on this site .

Parts Used:

-

Jimmy from FREEPORT, NY

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Pliers, Socket set

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!