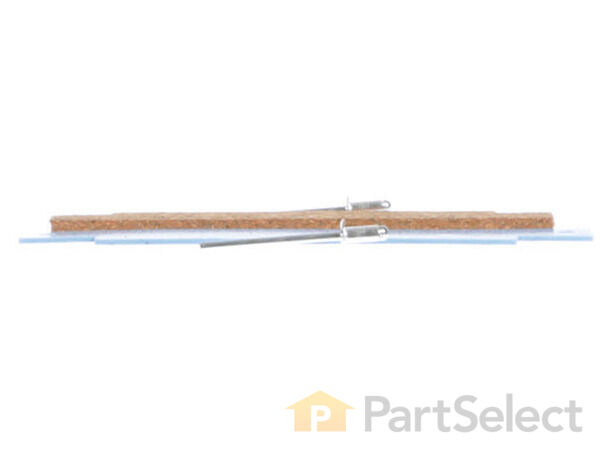

Front Glide Kit 306508

Rated by 78 customers

Easy

1- 2 hours

Ratings submitted by customers like you who bought this part.

Get this part fast! Average delivery time for in-stock parts via standard shipping: 1.8 days.

Front Glide Kit Specifications

How Buying OEM Parts Can Save You Time and Money

Replacing your Maytag Dryer Front Glide Kit

-

5 Stars 36

-

4 Stars 2

-

3 Stars 0

-

2 Stars 0

-

1 Star 0

- < Prev

- 1

- 2

- 3

- Next >

- < Prev

- 1

- 2

- 3

- Next >

- < Prev

- 1

- 2

- 3

- Next >

-

Bruce from FAIRMONT, WV

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

-

Peter from PEABODY, MA

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers

-

Fred from GREENCASTLE, PA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

Remove the old felt seal both front and back. Vacuumed and cleaned the interior of the dryer blowing out the heat coils and controls on the front panel. Removed and replaced the front guides and install ... Read more ed new rollers. Removing the old glue holding the felt required a heat gun and scraper. New felt was installed with the proper glue and clamped in place for 12 hours. Assemble the the dryer in reverse order.

-

Gary from BOTHELL, WA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers

-

Dave from CRANBERRY TWP, PA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Pliers, Screw drivers, Socket set

-

Rita from SAN DIEGO, CA

-

Difficulty Level:Very Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

-

Robert W from OTSEGO, MI

-

Difficulty Level:Easy

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Screw drivers, Socket set, Wrench (Adjustable)

-

Fred from COLUMBIA FLS, MT

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set, Wrench (Adjustable)

-

Buck from FLORENCE, AL

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers

-

John from COHUTTA, GA

-

Difficulty Level:Easy

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set, Wrench set

- < Prev

- 1

- 2

- 3

- Next >

Ask our experts a question about this part and we'll get back to you as soon as possible!

- < Prev

- 1

- 2

- Next >

16 people found this helpful.

13 people found this helpful.

10 people found this helpful.

8 people found this helpful.

5 people found this helpful.

4 people found this helpful.

4 people found this helpful.

2 people found this helpful.

1 person found this helpful.

- < Prev

- 1

- 2

- Next >

Manufacturer Part Number: 306508

Item is in stock and will ship today if your order is placed before 4:00 PM Eastern Standard Time.

If your order is placed after 4:00 PM EST, the in stock items will ship on the next business day.

Item is not in stock and usually ships 3-5 business days from the time you place your order.

Item is not in stock and usually ships 10-15 business days from the time you place your order.

This item is no longer being made by the manufacturer, and cannot be added to your shopping cart.