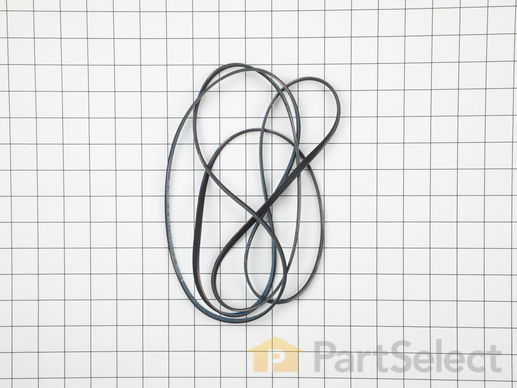

Drum Belt 134503600

Rated by 93 customers

Easy

1- 2 hours

Ratings submitted by customers like you who bought this part.

Get this part fast! Average delivery time for in-stock parts via standard shipping: 1.8 days.

Drum Belt Specifications

How Buying OEM Parts Can Save You Time and Money

Replacing your Frigidaire Dryer Drum Belt

-

5 Stars 46

-

4 Stars 4

-

3 Stars 2

-

2 Stars 2

-

1 Star 1

- < Prev

- 1

- 2

- 3

- Next >

- < Prev

- 1

- 2

- 3

- Next >

- < Prev

- 1

- 2

- 3

- Next >

-

David from EDGEWOOD, NM

-

Difficulty Level:Easy

-

Total Repair Time:More than 2 hours

-

Tools:Screw drivers

-

Linda from COVINGTON, KY

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers

-

Christopher from DENVER, PA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

It took a long time to clean all the lint out from the inside of the dryer. The motor was completely embedded with lint and animal hair. You may want to suggest that a good cleaning may be needed so bring a shop vac...and also something to carefully pick the lint balls out from around the motor armature and bearing area. Overall the video instructions were really a big help!

-

John from WESTLAKE, OH

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers

-

Stephen from HICKSVILLE, OH

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set

-

FRANK from VERO BEACH, FL

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Screw drivers, Socket set, Wrench set

-

Isaias from LAREDO, TX

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers, Socket set

-

Sharon from UXBRIDGE, MA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

-

Cherry from WATERVLIET, NY

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers

-

Christy from BRIDGEPORT, OH

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers, Socket set

- < Prev

- 1

- 2

- 3

- Next >

Ask our experts a question about this part and we'll get back to you as soon as possible!

- < Prev

- 1

- 2

- 3

- Next >

38 people found this helpful.

14 people found this helpful.

12 people found this helpful.

6 people found this helpful.

5 people found this helpful.

5 people found this helpful.

4 people found this helpful.

3 people found this helpful.

3 people found this helpful.

1 person found this helpful.

- < Prev

- 1

- 2

- 3

- Next >

Manufacturer Part Number: 134503600

Item is in stock and will ship today if your order is placed before 4:00 PM Eastern Standard Time.

If your order is placed after 4:00 PM EST, the in stock items will ship on the next business day.

Item is not in stock and usually ships 3-5 business days from the time you place your order.

Item is not in stock and usually ships 10-15 business days from the time you place your order.

This item is no longer being made by the manufacturer, and cannot be added to your shopping cart.