SWSG1031HS0 Westinghouse Washer Dryer Combo - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Wretched screeching noise

Make sure you order a new belt and a new drum glide with the rear drum bearing assembly. If your bearing is worn out, so are the belt and drum glide!

1) Use a flat screw driver or putty knife to release the blind clips that hold the front side of the top of the dryer cabinet down

2) Swing dryer top up and remove two screws that hold the face of the cabinet.

3) Unplug the wiring harness and remove the cabinet face.

4) Remove the 3 screws that hold the drum to the bearing assembly (accessed from inside the drum. This makes it easier to remove the drum as the bearing assembly can be difficult to remove before you see how it snaps together

5) Reach under the drum and take the belt off the motor pulley, then remove the drum

6) Remove the old bearing assembly from the socket (slide up then out)

7) Remove the two screws that hold the bearing socket to the dryer

8) Fasten the new socket to the dryer (you'll need help doing this unless you have REALLY long arms because you have to reach inside the driver and the back of the dryer at the same time)

9) Grease the socket with the supplied high temp grease

10) Bolt the new bearing assembly to the drum and put the new belt around the drum

11) Put the drum back in and snap the bearing socket in and down

12) Guide the new belt around the motor pulley & tensioner

13) Glue the new drum glide / felt piece to the front cabinet

14) Put the cabinet back together

1) Use a flat screw driver or putty knife to release the blind clips that hold the front side of the top of the dryer cabinet down

2) Swing dryer top up and remove two screws that hold the face of the cabinet.

3) Unplug the wiring harness and remove the cabinet face.

4) Remove the 3 screws that hold the drum to the bearing assembly (accessed from inside the drum. This makes it easier to remove the drum as the bearing assembly can be difficult to remove before you see how it snaps together

5) Reach under the drum and take the belt off the motor pulley, then remove the drum

6) Remove the old bearing assembly from the socket (slide up then out)

7) Remove the two screws that hold the bearing socket to the dryer

8) Fasten the new socket to the dryer (you'll need help doing this unless you have REALLY long arms because you have to reach inside the driver and the back of the dryer at the same time)

9) Grease the socket with the supplied high temp grease

10) Bolt the new bearing assembly to the drum and put the new belt around the drum

11) Put the drum back in and snap the bearing socket in and down

12) Guide the new belt around the motor pulley & tensioner

13) Glue the new drum glide / felt piece to the front cabinet

14) Put the cabinet back together

Parts Used:

-

Paul from Broadalbin, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

9 of 9 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Timer knob broke

I went online with Model number and put in a search for a timer knob. The piece I ordered turned out to be the timer knob for the washer (stackable washer/dryer unit). I called and ordered the correct part and had to mail back the 1st one. I learned that it is better to speak with a person when ordering parts to make sure you are getting the correct on. You can avoid a lot of expense for postage this way. Once I had it, it was just a matter of sliding it on to the metal post on the dryer.

Parts Used:

-

HARRY from Woodinville, WA

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

10 of 12 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer control switch was broken

I pulled the panel removing 4 screws then removed the switch panel by removing the two screws holding that in place. I pulled the switch panel down and removed the 2 screws holding the switch in place. I then removed the two wires connecting the switch and reinstalled everything. The whole process was less than 15 minutes.

Parts Used:

-

Robert from Galeton, PA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

11 of 16 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The Dryer Drum Would Not Move. Motor Worked But Drum Didnt.

First I read the manual on how to replaced the dryer drum belt. Second I took off the front panel. This would involving taken all screws from the top of the dryer face and the front panel. Thirdly I removed the exhaust attachment. Then I saw that the belt broke. Really it looked torned apart. I believe too heavy of a load in dryer. I then installed the new belt and reversed everyhing I did to start. The dryer runs great. This is not that bad of a job. If you can do it yourself, why pay hunreds on a service man to do the job.

Parts Used:

-

steven from parrish, FL

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers

10 of 13 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

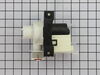

leaking water inlet valve

removed the two 'lock down flanges' from the back of the machine, lifted the top from the front and slid it forward to access the valve. Removed the two electrical connections then the compression ring from the hose on the output side. Removed two screws holding the valve in place, then reversed the process.

I wish this valve was made of metal rather than plastic. I had to replace it because the threads were stripped. Here's the heads up. Make sure the fittings on your supply hoses are 'clean' or you'll mess up the plastic threads and not get a good seal.

I wish this valve was made of metal rather than plastic. I had to replace it because the threads were stripped. Here's the heads up. Make sure the fittings on your supply hoses are 'clean' or you'll mess up the plastic threads and not get a good seal.

Parts Used:

-

Steven from Oklahoma City, OK

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

9 of 11 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

agitator was stripped, so it kept slipping.

removed old agitator by loosing a bolt at top, after removing the detergent dispenser. agitator came off easily, new one on, bolt on with rachet wrench, dispencer on. works like new. thanks for the great service. the part came in faster than i thought it would, and i would have had to travel for miles to get a part around here. VAL

Parts Used:

-

VALERIE from TUPPER LAKE, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers, Socket set

12 of 20 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

No hot Water to washing machine

S/O Water , Removed front panel, removed screws from side panel water valve accessible. Removed screws that hold water valve, installed new valve reassembled washing machine.

Parts Used:

-

Dominick from Las Vegas, NV

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers

9 of 11 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Water valve not shutting off correctly

After the new replacement part arrived, I took off the complete back panel (after unplugging the electrical and shutting off the hot & cold water supply). I disconnected both hot & cold water hoses, unscrewed the 2 screws holding the water valve, unplugged the 2 electrical wires for the water valve sending unit, unclamped the outlet water hose. Then I reversed order with new water valve. Put everthing back together in about 20 minutes overall. I did also replace the hot & cold water supply hoses with a better quality hose. Works like new! Thank you very much.

Parts Used:

-

Eric from Sebastopol, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

9 of 11 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

washer went into spin mode but would not spin

I removed the front panel to see the belt was snapped in two. The front roller is sping loaded, so I gave it a little tention, slid the belt back on and viola! it was that easy. If your washer starts to vibrate more and sounds louder than normal, get a belt as soon as possible because that may be the problem. Once I put on the new belt, the machine ran as quiet as it did when I first bought it.

Parts Used:

-

Damon from Hinesville, GA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

9 of 12 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The threaded male coupling on the water inlet valve is plastic and broke during moving.

I installed this part on a stackable washer-dryer unit. First, I removed the hoses (one had broken off already, damaging the cold water coupling). Using a nut driver I removed the screws on both L-brackets in back that help secure the dryer unit to the washer base. Then, I located 2 other screws securing the dryer to the washer base. These were fairly accessible in the recess where the dryer exhaust vent is located, directly above the water inlet valve. I removed both with a nut driver. I thought I would have to also unscrew 2 more screws on the other side of the dryer, but these were not accessible. So I lifted the side of the dryer I had unbolted to get to the water inlet valve. And voila! It lifted up. I placed a 2x4 on edge to keep the dryer tilted open. The inlet valve is attached to the back inside of the washer by a single screw on the Kenmore, which I removed with a phillips screw driver. Reaching inside the back of the washer, I disconnected the water hose by pinching the retaining clip with pliers. Then I pulled the electrical connections off the the hot and cold solenoids and the unit came out. The replacement unit was installed in reverse.

Parts Used:

-

Alan from Denver, CO

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Pliers, Screw drivers

8 of 9 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Wash tub would not drain/burning rubber smell

I removed the top of the washer by removing two screws on the back. I located and bypassed the lid switch to make sure that wasn't the problem. The problem still existed so I removed the two screws that hold the front panel of the washer. Using a flashlight, I located the drive belt and immediately saw that it was out of position and had pieces missing. I cut and removed the old belt, placed the new belt on the tub pulley and slowly maneuvered it onto the motor drive wheel. I then squeezed the tensioner pulley so that the belt was seated. I turned the timer dial which started the washer and it immediately began pumping the water out of the tub. Problem solved!

Parts Used:

-

Clay from Kansas City, MO

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

9 of 13 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Agitator making clunking niose

Removed the top of agitato removed bolt, R&R part ,put bolt an top back 3min. Top

Parts Used:

-

Lee from Willcox, AZ

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Socket set

11 of 19 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Spin Cycle wouldn't work

Replaced pump, by removing back panel and removing the two screws holding the pump to the bottom of the machine. The only difficult aspect was dealing with the hose clamps, these were extremely awkward to work with in a confined space. The repair would have been less than 30 min if the hose clamps weren't so difficult to put back in place.

Parts Used:

-

KEITH from BEND, OR

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set

9 of 13 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer runs but produces no heat

Unplug the unit. The top of the dryer is held down by 2 simple friction pins. By lifting the dryer top above it's front door panel the top will swing up. Prop the top up so you can reach down the front panel. There are 2 Phillips screws about 6 inches down on the dryers front panel. Remove the 2 screws, tip the front panel toward you it will slip off the dryer drum. Remove the 2 push on wires attached to the door switch. Gently lift the front panel off the 2 hinge points at the bottom and set it aside. The parts that your going to replace are the 2 solenoids on the burner assembly. The burner assembly is located on the lower left side of the dryer. Remove the 2 Philips screws that "clamp" the solenoids in place. Pull the 3 & 2 wire friction connectors off the solenoids. Lift the clamp off the top of the solenoids. Pick the 2 solenoids up off the valve assemble. Put the 2 new solenoids on the valve assembly push the wires back on, put the clamp back on and resemble the dryer. *Note: just to make a quick check on the continuity of the solenoids. I suspended the dryer drum so it could rotate without damaging it, put my clamp on amp probe on the 120v line to the solenoids the 3 wire one was good the 2 wire one was open.

Parts Used:

-

Richard from Appleton, ME

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

7 of 8 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Bearing Bracket Worn Out

Took off front panel, removed drum and replaced parts listed. A bit tricky to keep small parts in place. However, masking tape helped. Best of all was the online diagram of how the parts were assembled. In addition, taking step by step phone pixs aided in replacing parts since there was some down time between diagnosis and installation.

Parts Used:

-

David from Fairdale, KY

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

21 of 24 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!