NDG6800AWW Maytag Dryer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Replaced two parts in the gas heater assembly

I removed the front panel of the dryer by removing the 2 screw that secure it at the bottom and pulling upward to disconnect the cover at the top. I then removed the two screws that hold the metal cover that secures the 2 elements in place. I disconnected the wire plugs from the 2 elements, removed the 2 elements and replaced them with the new parts making sure to place them in the same positions as before. I then replaced the housing cover and tightened the screws. Then I replaced the front cover of the dryer.

Parts Used:

-

L R from Carmel, NY

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

20 of 26 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Rear Felt seal came out, squealing sound when drying

Turned off gas and unplugged dryer

1) Removed bottom front panel

2) lifted top panel up like a car hood

3) Removed door springs

4) disconnected electrial connections to door unit, removed door unit

5) removed drum, scraped old felt from drum

6) glued new felt with a very strong glue (nanoglue or gorilla glue, same thing), let it dry overnight

7) secured back inside panel, replaced drum and put dryer back together.

1) Removed bottom front panel

2) lifted top panel up like a car hood

3) Removed door springs

4) disconnected electrial connections to door unit, removed door unit

5) removed drum, scraped old felt from drum

6) glued new felt with a very strong glue (nanoglue or gorilla glue, same thing), let it dry overnight

7) secured back inside panel, replaced drum and put dryer back together.

Parts Used:

-

Matthew from Lombard, IL

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers

19 of 24 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Display was frozen

First I performed a keypad check by measuring the contacts on the keypad connector per the service manual I found online. All buttons appeared to be functional. I purchased both the LED Electronic Board and the KeyPad. Turns out the problem was with the KeyPad (stuck key) even though all key seemed to have checked out. So now the dryer is functioning with just the replaced Keypad and I have an extra LED Electronic Control Board.

Parts Used:

-

Richard from POTTSTOWN, PA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

18 of 22 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer was not heating

My 20 year old reliable Maytag 512 lgp dryer was not heating anymore. At first the heating element would glow red but not hot enough to ignite the gas. I replaced the element and it worked for a few loads but then stopped reigniting after the first cycle.

After some research and diagnosis (checking connections, amperage flow on each electriical part, etc.) I determined that the two coils were faulty. I ordered parts and replaced them (easy to do) and it worked again, for another few loads. Then nothing worked. The coil did not get hot and I did not hear the clicking sound that initiates current flow to the ignitor through the coils.

I checked the coils and ignitor again, they were fine. Frustrated, I called in a repairman to diagnose the problem. $55 and 15 min later he narrowed it down to the High Limit Thermostat. To demonstrate he bypassed the thermostat by directly connecting the two leads together and the ignitor fired right up.

His price to replace the thermostat? $45 part plus $130 labor. I bought the thermostat online for less than half his parts cost and the labor took me 5 minutes. Simply unscrew the small screws with a small socket set or nutdriver and replace the thermostat. Just two connectors, real simple.

All in all it was very easy to replace the parts, just tricky to diagnose unless you are good with electrical work.

After some research and diagnosis (checking connections, amperage flow on each electriical part, etc.) I determined that the two coils were faulty. I ordered parts and replaced them (easy to do) and it worked again, for another few loads. Then nothing worked. The coil did not get hot and I did not hear the clicking sound that initiates current flow to the ignitor through the coils.

I checked the coils and ignitor again, they were fine. Frustrated, I called in a repairman to diagnose the problem. $55 and 15 min later he narrowed it down to the High Limit Thermostat. To demonstrate he bypassed the thermostat by directly connecting the two leads together and the ignitor fired right up.

His price to replace the thermostat? $45 part plus $130 labor. I bought the thermostat online for less than half his parts cost and the labor took me 5 minutes. Simply unscrew the small screws with a small socket set or nutdriver and replace the thermostat. Just two connectors, real simple.

All in all it was very easy to replace the parts, just tricky to diagnose unless you are good with electrical work.

Parts Used:

-

Mitch from Sacramento, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver, Screw drivers, Wrench set

21 of 32 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Temperature setting not working

Took off back cover, thermostat was easily identified because of photos I've seen on website. Took 2 connectors off, removed 2 screws and removed old thermostat. That was pretty much it!

NOTE: Replacement thermostat 694674 has an adjustable temperature range setting that MUST be manually set prior to installing! You need to use the enclosed chart to find your original part# and make sure the setting is matched. My original part# 341146 had a "D" setting so I had to change but very easy to do.

NOTE: Replacement thermostat 694674 has an adjustable temperature range setting that MUST be manually set prior to installing! You need to use the enclosed chart to find your original part# and make sure the setting is matched. My original part# 341146 had a "D" setting so I had to change but very easy to do.

Parts Used:

-

Robert from Buffalo, NY

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

17 of 20 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer wouldn't start

We tried replacing the door switch first, still didn't start. Next we tried the thermal fuse and it turned on and has worked ever since.

Parts Used:

-

SALLY from ANAHEIM, CA

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers, Screw drivers

16 of 18 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

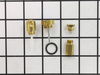

converted gas dryer to LP

Instructions were great. Very step by step. It could not have been easier. Repair saved me a $100 service call.

Parts Used:

-

Bruce from Rogers, AR

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Pliers, Wrench (Adjustable)

16 of 18 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

broken clip for door latch

popped out old female clasp on dryer itself with screwdriver, undid 2 screws on dryer door and door handle with phillips screwdriver, popped in new male clasp part, put door knob back on and put the two screws back in door and it was all set to go. Less than 15 minutes to do. Better than new and wife is happy. No more duct tape holding door closed now.

Parts Used:

-

Shawn from Dover, NH

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

14 of 15 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Time clock not moving .Not enough heat

Opened front panel .Tested both coils on gas valve.

Found no continuity on one of the coils. Replaced coil,

dryer works like new.

Found no continuity on one of the coils. Replaced coil,

dryer works like new.

Parts Used:

-

PHILIP from LONG ISLAND CITY, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers, Screw drivers

16 of 21 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

an electrician fried the control board while doing other work on house

Removed back cover from control panel, unscrewed screws securing panel and unplugged wire leads, then removed. Replaced with new panel by plugging back in wire leades(color coded,very easy) resecured board and cover. Done

Parts Used:

-

Richard from Lyndhurst, OH

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

14 of 17 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

drum would not spin and would trip the overload protector

pulled the motor and replaced it and not having any issues since.

Parts Used:

-

joshua from longmont, CO

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers, Socket set

21 of 38 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Burner would not go on on my Stack Set Dryer

Took out two front Panel screws and removed the panel. Removed Gas solenoid coil holding bracket by removing two phillips head screws. Disconnected the coil leads. and removed the coils. Connected the new coils to the leads and set in place. Replaced the holding bracket and the two screws. Replaced the front cover and the two front cover screws. Piece of Cake!

Parts Used:

-

Robert from North East, PA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

16 of 24 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer runs, but no heat

Removed screws in hinges and on opposite side inside the door to remove the front panel.

You can put the door back on at this point to run the dryer with the burner exposed. At this point I could tell that the igniter was working and the gas valve would occasionally work so that burner would fire. The valve only seemed to work when everything was completely cooled down. I first replaced only the solenoid coils on top of the valve, this did not fix the problem. When I replaced the entire valve the problem was fixed.

Replacing the valve is easy.

1) Unplug dryer from wall outlet

2) Turn off gas supply cutoff valve

3) Remove door and front panel

4) Unplug wires from solenoid coil terminals. There are two coils on top of the valve body.

5) Remove gas line from valve body.

6) Remove two screws which secure the bracket holding the valve body and burner nozzle to the bottom of the dryer cabinet.

7) Remove two screws which secure the valve to the bracket.

8) Reverse the procedure for installation of new valve.

You can put the door back on at this point to run the dryer with the burner exposed. At this point I could tell that the igniter was working and the gas valve would occasionally work so that burner would fire. The valve only seemed to work when everything was completely cooled down. I first replaced only the solenoid coils on top of the valve, this did not fix the problem. When I replaced the entire valve the problem was fixed.

Replacing the valve is easy.

1) Unplug dryer from wall outlet

2) Turn off gas supply cutoff valve

3) Remove door and front panel

4) Unplug wires from solenoid coil terminals. There are two coils on top of the valve body.

5) Remove gas line from valve body.

6) Remove two screws which secure the bracket holding the valve body and burner nozzle to the bottom of the dryer cabinet.

7) Remove two screws which secure the valve to the bracket.

8) Reverse the procedure for installation of new valve.

Parts Used:

-

doug from dallas, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers, Wrench (Adjustable)

13 of 16 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The dryer was not fully drying

After replaceing several parts including the thermostats the last part I replaced the coils were the defective part. I originally metered out the themostats and they appeared to be okay but since this was my first time I thought I might have been mistaken. It turns out the last part I thought it could be was the part that was defective. I will say that it is very simple to replace any of the parts involved. The hardest part was trying to open the dryer itself. But after having to do it 3 times, I'm now a pro. I also replaced the drum belt and since I had it open I also replaced the belf idler with a newer modified idler rolller.

Putting the belt back on is easy, but it helps to view the video or a picture to understand how the belt goes around it.

Putting the belt back on is easy, but it helps to view the video or a picture to understand how the belt goes around it.

Parts Used:

-

Michael from Chicago, IL

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers, Socket set

12 of 14 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

drum support roller was squeaking

My 11 year old grandson and I did the repair together. He had a blast and I did too. First we removed a bunch of screws that got us no closer to getting the machine apart than when we started. Then I remembered from the last time I had the machine apart that there are two screws just below the door, angled as not to be visable unless you know where to look. Once we removed those the from came off. We removed the wires for the door light and heat sensor, remembering the order of the wires for later reinstallation. Then we undid the bolts holding down the top. Once the top was removed we took off the belt and removed the drum. We used the retainer pliers to remove the retainer ring from the first roller. We removed the roller and also the shaft as this roller was the noise maker and the shaft was not in reusable condition. We installed a new shaft, roller washer, roller, another roller washer and then the retainer ring. We repeated the same process on the other roller, although we did not replace the shaft as it was in good condition. It turned out I did not need to order the shaft washers as the rollers came with washers. Oh well, its not a good job unless you have parts left over when you are done. Once we replaced the rollers we commenced reinstallation. But first we had to google for diagram of the proper belt installation, which we found and that got the drum and belt installed properly. Thankd god for the internet. Once we had the drum installed we put the machine back together in the opposite order we took it apart. An operational test showed we did the job right, no more squeaking. The only injury was my grandson cut his thumb right after I gave him the speech about watching where your hand is going to end up when that bolt breaks free. It broke loose and into the metal bracket went his thumb. Oh well it was a good lesson and it was not a bad cut. All in all a good repair.

Parts Used:

-

Kevin from San Diego, CA

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers, Socket set

12 of 14 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!