LSG7806AAE Maytag Washer Dryer Combo - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Dryer would not shut off on auto dry settings

I removed the discharge duct from the back of the dryer. Then, I removed the screws on the back of the dryer and the back itself. This exposed the cycling thermostat. I removed the screw holding the thermostat. I took the wires off the defective thermostat and reinstalled them on the new thermostat. Then, I reassembled in reverse order.

Parts Used:

-

Wiliam from Belleville, MI

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver

36 of 41 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The dryer drive belt broke. The dryer wouldn't tumble nor blow heated air.

The repair itself was pretty easy. Though I had figured out what needed to be done on my own while I waited for the belt to arrive via Fed Ex, the belt arrived with instructions that described the plan I had already figured and if I hadn't known what I was doing, the instructions would have been a great help.

STEP ONE, UNPLUG THE UNIT (and/or shut off the gas supply), CAREFULLY. Then, I took the front of the unit off by removing the 2 screws on the front panel near the bottom of the unit and disconnected the wiring that shuts the unit off when the door is opened. Set the front door panel aside. Then I removed the front of the tumbler retainer along with the exhaust duct and lint screen assembly by removing 4 screws that affixed the reatiner frame to the rest of the outer cabinet. Set this aside as well. Remove the entire tumbler unit. Set aside. Remove 4 screws on the back of the unit that hold the tensioner and motor access panel and remove it. Set it aside. At this point, I vacuumed every bit of lint and debris from the snapped belt out of the enitre unit, lubricated/greased all moving parts, cleaned off the friction bearing surfaces, and collected loose change ($1.35).

When the belt arrived, I unwrapped it, and placed the smooth side to the tumbler and rubber banded the slack off to the bottom right side (sort of the 4:30 position as you put the tumbler back into the unit). I carefully jimmied the tumbler back into the unit BEING CAREFUL not to pinch the groved belt between the tumbler and any other parts inside the cabinet. I replaced the tumbler retainer and screwed the 4 bolts back into place. I spun the tumbler over near the tensioner assembly (so I could see the slack through the access panel hole in the back) and removed the rubber band. I threaded the belt through the tensioner and over the drive pulley and rotated the tumbler clockwise to align the drive train of the belt. I plugged the 2 wires back into the switch on the inside of the door panel and then I replaced it on the front of the unit and screwed the 2 screws back in at the bottom front of the panel. I plugged the unit back in and tested opperation. It worked great! I unplugged the unit again (I'm not finished yet). I then replaced the access panel on the back of the unit and screwed the 4 screws back in. I moved the unit back against the wall and plugged it back in. Done! The dryer is less noisey now and more efficient most likely b/c I cleaned all the lint out of the thing! Thanks for the prompt shipment of the belt!! I'll get a few more years out of this dryer before spending $700 on a new one!!! Thanks again!

STEP ONE, UNPLUG THE UNIT (and/or shut off the gas supply), CAREFULLY. Then, I took the front of the unit off by removing the 2 screws on the front panel near the bottom of the unit and disconnected the wiring that shuts the unit off when the door is opened. Set the front door panel aside. Then I removed the front of the tumbler retainer along with the exhaust duct and lint screen assembly by removing 4 screws that affixed the reatiner frame to the rest of the outer cabinet. Set this aside as well. Remove the entire tumbler unit. Set aside. Remove 4 screws on the back of the unit that hold the tensioner and motor access panel and remove it. Set it aside. At this point, I vacuumed every bit of lint and debris from the snapped belt out of the enitre unit, lubricated/greased all moving parts, cleaned off the friction bearing surfaces, and collected loose change ($1.35).

When the belt arrived, I unwrapped it, and placed the smooth side to the tumbler and rubber banded the slack off to the bottom right side (sort of the 4:30 position as you put the tumbler back into the unit). I carefully jimmied the tumbler back into the unit BEING CAREFUL not to pinch the groved belt between the tumbler and any other parts inside the cabinet. I replaced the tumbler retainer and screwed the 4 bolts back into place. I spun the tumbler over near the tensioner assembly (so I could see the slack through the access panel hole in the back) and removed the rubber band. I threaded the belt through the tensioner and over the drive pulley and rotated the tumbler clockwise to align the drive train of the belt. I plugged the 2 wires back into the switch on the inside of the door panel and then I replaced it on the front of the unit and screwed the 2 screws back in at the bottom front of the panel. I plugged the unit back in and tested opperation. It worked great! I unplugged the unit again (I'm not finished yet). I then replaced the access panel on the back of the unit and screwed the 4 screws back in. I moved the unit back against the wall and plugged it back in. Done! The dryer is less noisey now and more efficient most likely b/c I cleaned all the lint out of the thing! Thanks for the prompt shipment of the belt!! I'll get a few more years out of this dryer before spending $700 on a new one!!! Thanks again!

Parts Used:

-

Lee from Royal Oak, MI

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers, Socket set

35 of 41 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

belt was slipping

-

ROBERT from MORGAN CITY, LA

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

38 of 50 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer motor start windings burned up

The motor was easy to replace: unplug the wiring harness, slip off the belts, release the tension springs from the motor carriage with needle-nose pliers, and then unbolt the motor carriage with socket set and remove from the washer. Remove the pulley from the old motor with allen wrench and transfer the carriage to the new motor. Reverse operation for everything and you are back in business. The hardest part was the far back screw holding the carriage, a wobble extension helped.

Parts Used:

-

Eric from Seabeck, WA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers, Socket set

36 of 47 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer would light at start and then not light.

I used the trouble shooting part of this site and bought the radiant flame sensor and the high limit thermostat. Installation was very easy. The original problem still persisted and then purchased the temp. control thermostat, cycling thermostat and thermal fuse. These parts installed easily as well and the problem still existed.

While using the Multimeter to determine if the gas valve coils were getting voltage during the lighting process I moved the contacts on the two wire coil and noticed that the coil would activate sporadically. As it turned out the coil had a loose connection which would contact while cool and then lose contact when the coil warmed up.

This was a tricky issue to diagnose and am now waiting for a new coil to finish the repair.

I now have an almost complete set of spare parts for electrical issues and got them at a nice price. I will keep them in the event that I might need some of them in the future.

The repair would have been easy and very straight forward thanks to this website if the actual problem hadn't been the crazy heat related bad connection in the coil. Since the flame would light during startup the coils seemed to me to be good. Actually finding a weird issue is the sort of thing I find to be the fun part of repairing things.

Thanks Parts Select ! !

Gregg heagney

While using the Multimeter to determine if the gas valve coils were getting voltage during the lighting process I moved the contacts on the two wire coil and noticed that the coil would activate sporadically. As it turned out the coil had a loose connection which would contact while cool and then lose contact when the coil warmed up.

This was a tricky issue to diagnose and am now waiting for a new coil to finish the repair.

I now have an almost complete set of spare parts for electrical issues and got them at a nice price. I will keep them in the event that I might need some of them in the future.

The repair would have been easy and very straight forward thanks to this website if the actual problem hadn't been the crazy heat related bad connection in the coil. Since the flame would light during startup the coils seemed to me to be good. Actually finding a weird issue is the sort of thing I find to be the fun part of repairing things.

Thanks Parts Select ! !

Gregg heagney

Parts Used:

-

Gregg from Sedro Woolley, WA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

31 of 33 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer would start and heat, but after 1st cycle the burner would not fire and a buzzing sound was coming from the gas valve solenoid area. Igniter and other functions worked fine.

Removed front of dryer, unplugged each coil to determine where buzzing was coming from.....determined it was the boosting coil....ordered part and replaced. Dryer works great....we think it had be going bad over time because drying times have noticeable decreased.

Parts Used:

-

David from Bedford, IN

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Wrench (Adjustable)

31 of 36 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

dryer would not continuously heat, and took several cycles to dry clothes. The flame would ignite and heat the dryer at first, but then would ignite and go out quickly for the rest of the cycle. I tried the thermostats first with no luck.

I first ordered the coils from a different web site and they sent the wrong ones. The job would have been much eaiser if i had just returned and ordered from here. Instead i cut wires and tried the others but since they were worng, it did not work. I didn't label the wires so it was a puzzle to put it back together. Once i had the wires connected properly it was a simple fix. You just open the top and take the front pannel off, remove the drum and it is right there at the bottom. Two screws take the cover off of the coils and they slide off the gas valve. Slide the new ones on and replace the cover. Put the front pannel back on, close the top and its good to go. I first tried the highlimit thermostat, and termostat with no luck. The flame would light when it was cold, but once warmed up, the flame would ignite and immediatly go out. The coils did the trick.

Parts Used:

-

Ryan from Livonia, MI

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Pliers, Screw drivers

30 of 34 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

My dryer only heats up at the beginning of cycle so my clothes will not dry.

I remove the front control panel and to get to the bottom front dryer door off. Using my volt meter i checked all the sensors and thermal. I surf the internet for hint and some one mention to replace the coil since some time you could have one goes out and the other working still. After i replaced the coil kit it works like a champ.

Parts Used:

-

Monique from Mission Viejo, CA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers, Socket set

31 of 38 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The water didn't pump out during the spin cycle

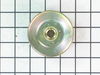

I took out the two screws in the bottom front panel of the washer, and rotated the front panel from the bottom away from the machine until the top or the panel was released from the machine frame. I then tilted the washer back to get access to the bottom of the machine. The pump pulley had split in half, and the bottom half fell off the drive motor shaft. The only problem I had was breaking free the set screw that holds the pulley to the drive motor shaft. I used a long arm Allen wrench and an adjustable "Cresent" wrench to apply enough force to break the set screw loose. Iclamped the upper transmission belts tightly to keep the motor shaft from turning while I loosened the set screw.

Parts Used:

-

Robert from Menomonee Falls, WI

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Wrench (Adjustable)

30 of 38 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer would dry for 5-10 minuets then no heat

I tested the dryer coils and found that they were getting a voltage but would not open the gas valve. Coils were not bad but weak. After they warmed up they would not open the gas valve. It took 10 min to repace both coils and the heat sensor.

Parts Used:

-

Richard from Jerome, MI

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers, Socket set

35 of 55 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Very loud intermittent squeeling when running

Remove top two front cover screws. Disconnect wiring. Set aside front cover - door assembly.

Remove two screws at top of the vertical riser cover to expose entire dryer interior. Remove filter. Remove screws to blower cover plate. Remove 4 screws that fasten front drum guide assembly. Remove drum. remove and replace 2 drum support rollers . Replace one rusted drum roller shaft. Replace both drum rollers and non-metalic washers.

Drill out 4 rivets holding two front drum glides. Replace and rerivet new drum glides.

Pry back slighty the many retention points around the front drum assembly which hold the front drum felt seal. Refit the new front drum felt, pressing the retaining clips back in place with a screwdriver.

Replace tumbler motor belt.

Install Drum. Install front drum retention assembly. Install new blower seal with reassembly of blower cover.

Total time - about 1 hour

Remove two screws at top of the vertical riser cover to expose entire dryer interior. Remove filter. Remove screws to blower cover plate. Remove 4 screws that fasten front drum guide assembly. Remove drum. remove and replace 2 drum support rollers . Replace one rusted drum roller shaft. Replace both drum rollers and non-metalic washers.

Drill out 4 rivets holding two front drum glides. Replace and rerivet new drum glides.

Pry back slighty the many retention points around the front drum assembly which hold the front drum felt seal. Refit the new front drum felt, pressing the retaining clips back in place with a screwdriver.

Replace tumbler motor belt.

Install Drum. Install front drum retention assembly. Install new blower seal with reassembly of blower cover.

Total time - about 1 hour

Parts Used:

-

Tom from Blue Bell, PA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers, Socket set

26 of 29 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer would not heat up.

I unplugged the dryer,removed the two small screws on the front of the dryer and pulled the bottom forward. The two wires connected to the door do not have to be removed. With an electrical tester using the Ohm setting I tested the Radiant sensor and the Gas Valve coils. The two terminal coil was DOA. The dryer can be operated with the front open as long as the door wires are connected. Symptons: The igniter would heat up and not release gas. My repair was successfull due to this awesome website and the super fast shipping service. AAAA++++

Parts Used:

-

Roger from Bonners Ferry, ID

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver, Screw drivers

26 of 29 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Heard squealing sound when washer went into the "spin" mode. Tub did not spin

Replaced the 2 belts according to instructions received with the belts. Very easy repair

Parts Used:

-

Edward from Stroudsburg, PA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

28 of 36 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Strange noises - drum not always emptying

Found a very stretched, loose pump belt. Was able to pull it off pump pulley and motor pulley easily. Pushed motor assembly toward transmission pulley and removed wider drive belt. Wiped all pulleys clean. There's a double on the motor- one for drive belt, one for pump belt. Removed two hoses from pump using nutdriver. Removed pump. New pump installed. Installed two hoses on new pump. Installed drive new drive belt. Installed pump belt last. Slid pump to near farthest spot in slots. Tested for correct tension by pinching pump belt. Should be able to pinch center so two pump belt sides come within 1/4" of each other just as the spring tensioned motor mount starts to move. Pused washer back into place after external hoses connected. All new hose washers and filters on both hot and cold. Ran, checked for leaks - none! Absolutely perfect. Put front panel back on. No weird noises and drum empties perfectly every time. My wife is so pleased she's doing more loads.

Parts Used:

-

Kenneth from Sunnyvale, CA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver

26 of 31 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Water inflow did not stop = flooded utility room

Cleaned up a wet utility room floor!

Unplugged power cord to the machine and turned off hot and cold water at the stop valves.

Removed the top machine screw that holds the metal panel with the valve attached (on the rear of the machine where hoses attach), removed it from the machine with valve and hoses attached.

Disconnected both water hoses at the old valve, together with the 1/2" hose to the machine. Mark hot and cold positions.

Moved the electrical contacts one-by-one to the new valve.

Changed the old valve for the new valve (one screw attaches to plate).

Connected the inlet hoses and 1/2" hose to the new valve, making sure hot/cold on correct positions.

Replaced plate in the machine and secured with the machine screw.

*** NO MORE WADING SINCE REPAIR *****

Unplugged power cord to the machine and turned off hot and cold water at the stop valves.

Removed the top machine screw that holds the metal panel with the valve attached (on the rear of the machine where hoses attach), removed it from the machine with valve and hoses attached.

Disconnected both water hoses at the old valve, together with the 1/2" hose to the machine. Mark hot and cold positions.

Moved the electrical contacts one-by-one to the new valve.

Changed the old valve for the new valve (one screw attaches to plate).

Connected the inlet hoses and 1/2" hose to the new valve, making sure hot/cold on correct positions.

Replaced plate in the machine and secured with the machine screw.

*** NO MORE WADING SINCE REPAIR *****

Parts Used:

-

Kevin from Chico, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

23 of 25 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!