SWSG1031HQ4 Westinghouse Washer Dryer Combo - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Burning odor, melted terminal block

0) Turned off breaker at panel and disconnected power cord from 240v wall outlet

1) Removed screws that hold electrical cover plate on back of dryer.

2) Lifted the top of dryer using putty knife on 2 top edges of lid. This lifts up like a cars hood.

3) Removed the screws that attach the power cord to the terminal block and disconnected power cord

4) Removed screws that attach terminal block to dryer

5) Removed melted terminals by prying out of terminal block. Note metal lip on terminal has to be lifted in order to slide connector out. Also unscrewed ground wire from terminal block to dryer.

6) Drew diagram of what color wires go to what terminals

7) Cut terminals off of wires and connected new terminals. Crimped closed and used butane solder torch to solder connection between terminal and wire

8) Reconnected terminals to terminal block by sliding in. **Note, had to file down the edges of the terminals using moto-tool to make it fit as they are connected together using break-away tabs that leave a large piece of metal connected not allowing to fit in terminal block

9) Reconnected terminal block to dryer and reconnected ground wire.

10) Reconnected power cord to terminal block with screws

11) Replaced cover over wiring terminal block

12) Reconnected power cored to 240ac wall outlet

13) Turned breaker back on

1) Removed screws that hold electrical cover plate on back of dryer.

2) Lifted the top of dryer using putty knife on 2 top edges of lid. This lifts up like a cars hood.

3) Removed the screws that attach the power cord to the terminal block and disconnected power cord

4) Removed screws that attach terminal block to dryer

5) Removed melted terminals by prying out of terminal block. Note metal lip on terminal has to be lifted in order to slide connector out. Also unscrewed ground wire from terminal block to dryer.

6) Drew diagram of what color wires go to what terminals

7) Cut terminals off of wires and connected new terminals. Crimped closed and used butane solder torch to solder connection between terminal and wire

8) Reconnected terminals to terminal block by sliding in. **Note, had to file down the edges of the terminals using moto-tool to make it fit as they are connected together using break-away tabs that leave a large piece of metal connected not allowing to fit in terminal block

9) Reconnected terminal block to dryer and reconnected ground wire.

10) Reconnected power cord to terminal block with screws

11) Replaced cover over wiring terminal block

12) Reconnected power cored to 240ac wall outlet

13) Turned breaker back on

Parts Used:

-

DAVID from DURHAM, NC

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

12 of 13 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

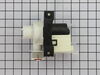

Washing machine wouldn't drain

i removed the front panel, then removed the old pump by taking off the clamps and disconnected the wiring. The new pump had to be reversed before connecting, but it was so easy.

Parts Used:

-

Siobhain from Ashland, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers

11 of 12 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

washer belt broke

-

Carl from Boxford, MA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

11 of 12 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

No heat/intermittent heat. Ignitor glowed but no gas flame.

White Westinghouse WDG547PB Dryer. Removed access panel (lower left front of dryer) by removing phillips head screw below access panel. Removed two phillips head screws holding bracket that holds coil in place. Removed coil, disconnected electrical connector. Connected electrical connector to new coil and set in place. Repeat for second coil. Reinstall bracket and access panel. Job complete. Dryer back in service with no problems.

Parts Used:

-

Jeffrey from Richmond, TX

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

11 of 12 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

CLothes weren't getting dry enough for the dryer.. also made a squeling, rubbing noise while aggitating. Had a repair man for my dishwasher..told him I thought it was the transmission.. he hand turned the aggitator and said that was the problem.. Just needed a new aggitator....whew what a relief!

I'm a 70 year old widow.. ordered the part which came in 2 days..(.very reasonably priced) My son came over and in no time had the old out and new in...works like a new machine... Thank you Part Select. A few months ago ordered a stove ignitor..it too came really fast... stove is good for another 15 years..LOL

Parts Used:

-

Bonnie from Trevor, WI

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Socket set

11 of 13 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Wretched screeching noise

Make sure you order a new belt and a new drum glide with the rear drum bearing assembly. If your bearing is worn out, so are the belt and drum glide!

1) Use a flat screw driver or putty knife to release the blind clips that hold the front side of the top of the dryer cabinet down

2) Swing dryer top up and remove two screws that hold the face of the cabinet.

3) Unplug the wiring harness and remove the cabinet face.

4) Remove the 3 screws that hold the drum to the bearing assembly (accessed from inside the drum. This makes it easier to remove the drum as the bearing assembly can be difficult to remove before you see how it snaps together

5) Reach under the drum and take the belt off the motor pulley, then remove the drum

6) Remove the old bearing assembly from the socket (slide up then out)

7) Remove the two screws that hold the bearing socket to the dryer

8) Fasten the new socket to the dryer (you'll need help doing this unless you have REALLY long arms because you have to reach inside the driver and the back of the dryer at the same time)

9) Grease the socket with the supplied high temp grease

10) Bolt the new bearing assembly to the drum and put the new belt around the drum

11) Put the drum back in and snap the bearing socket in and down

12) Guide the new belt around the motor pulley & tensioner

13) Glue the new drum glide / felt piece to the front cabinet

14) Put the cabinet back together

1) Use a flat screw driver or putty knife to release the blind clips that hold the front side of the top of the dryer cabinet down

2) Swing dryer top up and remove two screws that hold the face of the cabinet.

3) Unplug the wiring harness and remove the cabinet face.

4) Remove the 3 screws that hold the drum to the bearing assembly (accessed from inside the drum. This makes it easier to remove the drum as the bearing assembly can be difficult to remove before you see how it snaps together

5) Reach under the drum and take the belt off the motor pulley, then remove the drum

6) Remove the old bearing assembly from the socket (slide up then out)

7) Remove the two screws that hold the bearing socket to the dryer

8) Fasten the new socket to the dryer (you'll need help doing this unless you have REALLY long arms because you have to reach inside the driver and the back of the dryer at the same time)

9) Grease the socket with the supplied high temp grease

10) Bolt the new bearing assembly to the drum and put the new belt around the drum

11) Put the drum back in and snap the bearing socket in and down

12) Guide the new belt around the motor pulley & tensioner

13) Glue the new drum glide / felt piece to the front cabinet

14) Put the cabinet back together

Parts Used:

-

Paul from Broadalbin, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

9 of 9 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Felt around drum holder worn and torn.

1. Removed face of dryer (drum 'holder')

2. Disconnected door switch wires

3. Tore off existing felt

NOTE: The length of the felt that I recieved from PartSelect was incorrect (too short). Since the existing felt was worn and torn at the top, I replaced only a length that matched the length of the new felt.

4. Used a razor blade-type gasket remover/scraper to remove the exisitng glue

5. Applied new glue (which comes with the felt) onto the felt and let it set up

NOTE: In hindsite, I would apply the glue to the drum holder instead, as the glue otherwise soaks into the felt. If applied to the drum holder instead, the glue will spread out and provide more surface area for adherence.

6. Installed the new felt, starting at one end and working my way around to the other end, being careful not to stretch it

7. Trimmed the remainder of the existing felt (see first NOTE)

8. Scraped the drum holder below the pulled away ends of the exisitng felt

9. Applied glue to the existing felt, including the trrimmed ends so that the ends do not pull away from the ends of the new felt

10. Re-attached the existing felt

11. Let the glue set-up overnight

12. Reinstalled the face of the dryer, turning the drum so that the felt will not get pushed away

13. Reconnected the door switch wires

14. Turned dryer on, with lid still raised, to check for any drifting of the felt

15. Once assured that the felt would stay in place, put the dryer in service

NOTE: I replaced the felt becasue of the gap that opened due to compression of the felt. The gap, as well as a torn piece of the felt that entered the interior of the drum, was catching clothes and tearing them as they were rotated between the drum and the drum holder. The new felt eliminated this problem.

2. Disconnected door switch wires

3. Tore off existing felt

NOTE: The length of the felt that I recieved from PartSelect was incorrect (too short). Since the existing felt was worn and torn at the top, I replaced only a length that matched the length of the new felt.

4. Used a razor blade-type gasket remover/scraper to remove the exisitng glue

5. Applied new glue (which comes with the felt) onto the felt and let it set up

NOTE: In hindsite, I would apply the glue to the drum holder instead, as the glue otherwise soaks into the felt. If applied to the drum holder instead, the glue will spread out and provide more surface area for adherence.

6. Installed the new felt, starting at one end and working my way around to the other end, being careful not to stretch it

7. Trimmed the remainder of the existing felt (see first NOTE)

8. Scraped the drum holder below the pulled away ends of the exisitng felt

9. Applied glue to the existing felt, including the trrimmed ends so that the ends do not pull away from the ends of the new felt

10. Re-attached the existing felt

11. Let the glue set-up overnight

12. Reinstalled the face of the dryer, turning the drum so that the felt will not get pushed away

13. Reconnected the door switch wires

14. Turned dryer on, with lid still raised, to check for any drifting of the felt

15. Once assured that the felt would stay in place, put the dryer in service

NOTE: I replaced the felt becasue of the gap that opened due to compression of the felt. The gap, as well as a torn piece of the felt that entered the interior of the drum, was catching clothes and tearing them as they were rotated between the drum and the drum holder. The new felt eliminated this problem.

Parts Used:

-

Robert from York, PA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

10 of 12 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Tub was leeking

Lifted top

removed adgetator

removed tub top

removed inside tub

removed inside tub holder bracket

repaced seal

replaced,replaced.....

removed adgetator

removed tub top

removed inside tub

removed inside tub holder bracket

repaced seal

replaced,replaced.....

Parts Used:

-

Gregory from Fort Worth, TX

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set

13 of 22 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The Dryer Drum Would Not Move. Motor Worked But Drum Didnt.

First I read the manual on how to replaced the dryer drum belt. Second I took off the front panel. This would involving taken all screws from the top of the dryer face and the front panel. Thirdly I removed the exhaust attachment. Then I saw that the belt broke. Really it looked torned apart. I believe too heavy of a load in dryer. I then installed the new belt and reversed everyhing I did to start. The dryer runs great. This is not that bad of a job. If you can do it yourself, why pay hunreds on a service man to do the job.

Parts Used:

-

steven from parrish, FL

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers

10 of 13 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer would not turn on

I contacted a company to come out and diagnose the problem. They informed me that the thermal limiter is bad and needed to be replaced for $15 for the part and $85 labor. I found the part on this site for about $10, and did the repair myself. The dryer was mostly dismantled so I pulled the drum back, and replaced the part. The tricky part was the pulley system was, so make sure you see it before hand or find a diagram online. Once that was figured out, I set the drum back up, greased and tightened the pulley, reattached the front of the washer with connections, and closed the lid.

Parts Used:

-

Michael from Erlanger, KY

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers

9 of 10 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

leaking water inlet valve

removed the two 'lock down flanges' from the back of the machine, lifted the top from the front and slid it forward to access the valve. Removed the two electrical connections then the compression ring from the hose on the output side. Removed two screws holding the valve in place, then reversed the process.

I wish this valve was made of metal rather than plastic. I had to replace it because the threads were stripped. Here's the heads up. Make sure the fittings on your supply hoses are 'clean' or you'll mess up the plastic threads and not get a good seal.

I wish this valve was made of metal rather than plastic. I had to replace it because the threads were stripped. Here's the heads up. Make sure the fittings on your supply hoses are 'clean' or you'll mess up the plastic threads and not get a good seal.

Parts Used:

-

Steven from Oklahoma City, OK

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

9 of 11 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

agitator was stripped, so it kept slipping.

removed old agitator by loosing a bolt at top, after removing the detergent dispenser. agitator came off easily, new one on, bolt on with rachet wrench, dispencer on. works like new. thanks for the great service. the part came in faster than i thought it would, and i would have had to travel for miles to get a part around here. VAL

Parts Used:

-

VALERIE from TUPPER LAKE, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers, Socket set

12 of 20 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

No hot Water to washing machine

S/O Water , Removed front panel, removed screws from side panel water valve accessible. Removed screws that hold water valve, installed new valve reassembled washing machine.

Parts Used:

-

Dominick from Las Vegas, NV

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers

9 of 11 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Water valve not shutting off correctly

After the new replacement part arrived, I took off the complete back panel (after unplugging the electrical and shutting off the hot & cold water supply). I disconnected both hot & cold water hoses, unscrewed the 2 screws holding the water valve, unplugged the 2 electrical wires for the water valve sending unit, unclamped the outlet water hose. Then I reversed order with new water valve. Put everthing back together in about 20 minutes overall. I did also replace the hot & cold water supply hoses with a better quality hose. Works like new! Thank you very much.

Parts Used:

-

Eric from Sebastopol, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

9 of 11 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

washer went into spin mode but would not spin

I removed the front panel to see the belt was snapped in two. The front roller is sping loaded, so I gave it a little tention, slid the belt back on and viola! it was that easy. If your washer starts to vibrate more and sounds louder than normal, get a belt as soon as possible because that may be the problem. Once I put on the new belt, the machine ran as quiet as it did when I first bought it.

Parts Used:

-

Damon from Hinesville, GA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

9 of 12 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!