RS42*J4 Hotpoint Range - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

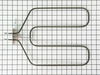

Both heating elements not working

Removed racks from oven. Each element had two screws, used socket wrench for all, gently pulled out element to exposé wiring removed wires with same socket. Once element out of oven, reattached wires to new element, reset element to back of oven and with the two screws attached back. Did the same process for top element only exception was a bracket holding top element from leaning down. It had two screws all the same size as element screws. Once all back in place turned on breaker to check each element.

Parts Used:

-

Brian from WATAUGA, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Socket set

5 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Electric Burner Control Broken

New one a little different ,but it was marked for wiring!

Had to install upside down because wires would not reach right side up!

Had to pull back side of knob out and turn 180 degrees and glue in knob, so knob would be right side up!

Works fine! Now all burners work again!

Had to install upside down because wires would not reach right side up!

Had to pull back side of knob out and turn 180 degrees and glue in knob, so knob would be right side up!

Works fine! Now all burners work again!

Parts Used:

-

Robert from VINELAND, NJ

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

4 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

no burnt wire

-

Bernard from N CHARLESTON, SC

-

Difficulty Level:Very Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

5 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Still need an other nut to keep broiler support inplcae. Support bar did not come with new screws so I must locate one new one.

I took out the old broiler support bar, but it was being held by one screw. I did install the new bar with one screw, but I need to obtain a second screw. I still have not located a second screw, but it is inplace.

Parts Used:

-

Donna from Sinking Spring, PA

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

6 of 11 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

infinite switch would not shut off at times.

First shut the power to the stove,then had to slide the stove out so I could get at the back to remove the panel screws.Once you have the back off remove the knob on the front.Under the knob is 2 phillips screws that you need to remove.Next I took the new switch and matched up the wires to the old switch.Reinstall is the reverse.Once the switch is in place you must remove the excess shaft to match the length of the old one.This is done with the use of 2 pliers,you grasp the shaft with both pliers and snap it off where you need it.The kit comes with spacers so you have got to match up the right one so the switch is solid on the shaft.This finishes the project,next turn the power back on and check that all is working ok.Job finished.

Parts Used:

-

Ervin from Milford, DE

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

6 of 11 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Oven/ No Heat

Partselect made this job a breeze. Due to the user friendly process to order and receive the part. I repaired the stove after turning off the breaker in the main box. There were two screws that held the baking unit in place, removed them and then replaced with new unit.

Parts Used:

-

A K from LITHIA SPRINGS, GA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver, Screw drivers

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Bad switch plus a disintegrating element

Moved into a house built in 1976 about 7 years ago that came with an old but nice looking GE electric stove.

Stove worked well until about a year ago when the switch for the 8" element became erratic. Having been raised where DIYS was SOP I didn't even consider calling for help instead, armed with the stove model number, I went to the internet (How on earth did I ever survive before internet?) and found this site where I quickly found the exploded view of my stove, IDed the switch, ordered and received it within a day or so. Fantastic turn around time!

Now I've never ever worked on an electric stove so I was quite methodical in my approach.

First I read the instructions (you know, when all else fails…) that came with the new switch, then I pulled the stove out, unplugged it and removed the tin back that covers the switches. I drew a diagram of the old switch orientation and which wires attached to what. Then I disconnected the wires, removed the knob and the two screws hiding behind it that hold the switch to the stove.

Oops, the new switch was not identical to the old!!

First: I noticed was that the stem for the knob was longer BUT they proved break off notches so that it can be shortened.

Second: the stem on the old switch was a half round while the new stem was square. I tried the 'half round' knob on the square stem and it went on firmly. Nothing ventured nothing gained.

Third: the terminal orientation did not match. So armed with my diagram and the instructions I made sure I knew which terminal was which (they are labeled). Once assured I knew what went where (I made notes) I installed the new switch and attached the wires (following my notes).

Being an optimist I reinstalled the tin back, plugged the stove in and pushed it back into position before (with my legs, arms and fingers crossed) I tested the switch (which was not easy considering the position I was in). Lo and behold, no puff of smoke and…ta-da…everything worked as it should.

All in all, upon receiving the switch the whole thing took less than 30 minutes.

Recent.

Less than two weeks ago one of the 6" elements fell apart, still worked but lost the supports that rest on the trim ring. Back to the internet to ordered a new element and new trim rings (just for the cosmetics). Again great service, I think I received my order the second day.

Along with the element they also supply new screws plus the spring clips which hold the ceramic insulator together. There's only two wires to contend with so its easy to determine which is the left wire and which is the right. The old terminal screws were locked in pretty good so I used pliers to hold the terminal while loosening them. There's very little slack in the wires so it was a tad awkward reattaching them to the new element.

I did notice that the threaded hole on the new element seemed to be slightly larger than the old. I noticed this when I used the old screws, one would tighten, the other did not so I replaced with the screws they supplied (Duh!). Well I do have an excuse, the new screws were longer which I feared would prevent the insulator from 'closing'.

I probably spent the most time attaching the insulator. I found I needed to fiddle with position of the terminals before the two halves of the insulator would meet. I splayed the wires out slightly then cocked the wire ends slightly so that the wires would neatly leave the side of the insulator. I also adjusted the terminals and the bendable wire part on the element so that they were parallel to each other.

ANYBODY can do this

Stove worked well until about a year ago when the switch for the 8" element became erratic. Having been raised where DIYS was SOP I didn't even consider calling for help instead, armed with the stove model number, I went to the internet (How on earth did I ever survive before internet?) and found this site where I quickly found the exploded view of my stove, IDed the switch, ordered and received it within a day or so. Fantastic turn around time!

Now I've never ever worked on an electric stove so I was quite methodical in my approach.

First I read the instructions (you know, when all else fails…) that came with the new switch, then I pulled the stove out, unplugged it and removed the tin back that covers the switches. I drew a diagram of the old switch orientation and which wires attached to what. Then I disconnected the wires, removed the knob and the two screws hiding behind it that hold the switch to the stove.

Oops, the new switch was not identical to the old!!

First: I noticed was that the stem for the knob was longer BUT they proved break off notches so that it can be shortened.

Second: the stem on the old switch was a half round while the new stem was square. I tried the 'half round' knob on the square stem and it went on firmly. Nothing ventured nothing gained.

Third: the terminal orientation did not match. So armed with my diagram and the instructions I made sure I knew which terminal was which (they are labeled). Once assured I knew what went where (I made notes) I installed the new switch and attached the wires (following my notes).

Being an optimist I reinstalled the tin back, plugged the stove in and pushed it back into position before (with my legs, arms and fingers crossed) I tested the switch (which was not easy considering the position I was in). Lo and behold, no puff of smoke and…ta-da…everything worked as it should.

All in all, upon receiving the switch the whole thing took less than 30 minutes.

Recent.

Less than two weeks ago one of the 6" elements fell apart, still worked but lost the supports that rest on the trim ring. Back to the internet to ordered a new element and new trim rings (just for the cosmetics). Again great service, I think I received my order the second day.

Along with the element they also supply new screws plus the spring clips which hold the ceramic insulator together. There's only two wires to contend with so its easy to determine which is the left wire and which is the right. The old terminal screws were locked in pretty good so I used pliers to hold the terminal while loosening them. There's very little slack in the wires so it was a tad awkward reattaching them to the new element.

I did notice that the threaded hole on the new element seemed to be slightly larger than the old. I noticed this when I used the old screws, one would tighten, the other did not so I replaced with the screws they supplied (Duh!). Well I do have an excuse, the new screws were longer which I feared would prevent the insulator from 'closing'.

I probably spent the most time attaching the insulator. I found I needed to fiddle with position of the terminals before the two halves of the insulator would meet. I splayed the wires out slightly then cocked the wire ends slightly so that the wires would neatly leave the side of the insulator. I also adjusted the terminals and the bendable wire part on the element so that they were parallel to each other.

ANYBODY can do this

Parts Used:

-

John from Merriam Woods, MO

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set

4 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Needed To Replace Drip Bowl

I just replaced them.

Parts Used:

-

DIANA from TINTON FALLS, NJ

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

4 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Plasticware melted onto burner

I removed the screw holding the tilt mechanism to the range top. Removed the clips holding the block together. Disconnected the two power leads on the old burner and replaced with the new burner. Closed the block around the leads. Screwed the tilt mechanism back to the range top and that was it!

Parts Used:

-

Charles from New Orleans, LA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers, Wrench (Adjustable)

4 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

lights blown out

-

Gerald from WINTERVILLE, GA

-

Difficulty Level:Very Easy

-

Total Repair Time:Less than 15 mins

6 of 12 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Element got hot spot

Easiest thing I've done. Shut off breaker. Unplug range. Pull out from wall (because this is a good time to remove the back, clean under and around the unit, check out the insulation and electrical contacts....or skip it, whatever). Open oven. Remove door (while ajar, pull up). Remove racks. Unscrew mounting plate from back interior wall. Set screws aside. Gently pull element forward until the leads and wires come through the insulation. Remove any strands of insulation that stuck to the leads and connectors. Unscrew leads. Keep left wire to the left and right wire to the right. DO NOT CROSS. Set screws aside. Discard old element. (This is a good time to clean your oven, if you haven't in a while.) If you cleaned oven, wait until dry. Position new element, feet down, in bottom of oven. Position left wire on left connector. Screw tightly BUT DO NOT BEND LEAD. IF YOU BEND IT, THEN DO NOT BEND IT BACK. CALL A PROFESSIONAL. Position right wire on right connector. Screw tightly BUT DO NOT BEND. IF YOU BEND IT, THEN DO NOT BEND IT BACK. CALL A PROFESSIONAL. Do not leave screws loose. Connection must be tight. Fire hazard, otherwise. If you bent nothing, then gently push element back through insulation until mounting plate is flush. Screw into position. Replace racks. Replace door. If you decide to check insulation and other leads, now is the time. I checked mine and it's a good thing I did.... Unscrew back plate of oven, keeping screws in order. Remove plate. Check that your new element and insulation aren't bunched up or otherwise in a hazardous state. You may notice burned or greasy insulation. You may see burned leads on light receptacle and broil element. If you do, then replace them, too. When finished with everything, replace back plate. Put range back into position, ensuring level and plumb. Plug in. Turn on breaker. Pat yourself on the back. You just saved $100-$250, depending on where you live.

Parts Used:

-

Shannon from LOUISVILLE, KY

-

Difficulty Level:Very Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver, Screw drivers

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Replace Oven light socket and light bulb in kitchen Range

1) Turn off power at circuit breaker panel

2) Slide out Range from wall

3) Unplug Range

4) Remove back panel and unplug electrical connections to socket

5) From front of oven, remove glass cover over old oven light bulb and remove flange that holds socket and bulb

6) Remove old socket from mounting flange and discard.

7) Place new socket into mounting flange

8) Screw mounting flange and new socket into the oven from front. Reattach electrical connections from back.

9) Screw in new light bulb from front

10) Replace existing glass cover over new light bulb and snap wire holder in place

11) Replace back panel

11) Plug in range

12) Slide range back to original position

13) Turn on power

Works like a charm! Thanks for having the parts after 30 years!

2) Slide out Range from wall

3) Unplug Range

4) Remove back panel and unplug electrical connections to socket

5) From front of oven, remove glass cover over old oven light bulb and remove flange that holds socket and bulb

6) Remove old socket from mounting flange and discard.

7) Place new socket into mounting flange

8) Screw mounting flange and new socket into the oven from front. Reattach electrical connections from back.

9) Screw in new light bulb from front

10) Replace existing glass cover over new light bulb and snap wire holder in place

11) Replace back panel

11) Plug in range

12) Slide range back to original position

13) Turn on power

Works like a charm! Thanks for having the parts after 30 years!

Parts Used:

-

Ronald from TUCSON, AZ

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers, Socket set, Wrench set

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Old infinite switch WB21X36771 broke...heating element stopped heating

1. Bought replacement part said to replace old switch.

2. Pulled old switch out.

3. Replacement part did not match. Would have to take entire switch panel apart to change to this part.

4. Multiple-part instructions very poor. For my switch unreadable.

5. Old part was "push to turn". New part was not.

6. Knob did not fit new switch. Old shaft was "D" shaped. New is square.

7. Gave up. Need to call repair shop.

8. Hope this helps.

2. Pulled old switch out.

3. Replacement part did not match. Would have to take entire switch panel apart to change to this part.

4. Multiple-part instructions very poor. For my switch unreadable.

5. Old part was "push to turn". New part was not.

6. Knob did not fit new switch. Old shaft was "D" shaped. New is square.

7. Gave up. Need to call repair shop.

8. Hope this helps.

Parts Used:

-

Richard from PLANO, TX

-

Difficulty Level:Very Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Pliers, Screw drivers

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

burner would not lay flat against surface of range.

Removed two clips that held the ceramic insulators in place. Removed two screws that held conductors to the burner. Replaced screws onto new burner unit, replaced ceramic insulators. Fastened clip to burner onto the range. Turned burner on and it worked great. Thank you for your quick responce to my order.

Parts Used:

-

John from Westbrook, ME

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver, Screw drivers

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Burner rings and drip pans stained

Lifted burner element to remove pressure on ring and drip bowl. Removed old parts and replaced in reverse order. This not intended to sound sexist, but my wife who is not particularily mechanically inclined performed the task on her own.

Parts Used:

-

Tommy from Hydro, OK

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!