LAT9356AAE Maytag Washer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

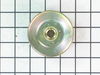

The washing machine ran noisily

Remove the power cord and water hoses. Lay the machine on the floor. Remove two belts (washing and pumping). Unlock the screw of pulley using a hex key. Remove the broken pulley from the motor. Place in the new pulley. Lock the screw of the pulley. Install two belts. Turn the machine vertically. Plug in water hoses and power cord. Level the machine.

Parts Used:

-

Xuanbao from Norwalk, CA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

5 of 9 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Upper and Lower Fill Injector snapped off and water was leaking out of the back of the machine

I looked at the machine diagram on the website and removed the screw on the bottom and lifted up the from panel which allowed me to have easier access to the fill injector. Then I removed the back panel off of the control panel on the top of the machine and removed the screw that held the fill injector in place, attached the new fill injector using the hose clamp I ordered with the part ( you need a new hose clamp because the other one is useless after you remove the old injector). Tightend up the screw to hold the injector in place and replaced the back panel and front panel. It was an easy repair and only cost $28.00 with shipping. I easily saved $150.

Parts Used:

-

Daryl from Newton, NJ

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Socket set

5 of 9 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

broken belt

Layed the machine on it'sback and put the 2 belts on the pulleys,Very easy ,when you know to put the machine on it's backside!

Parts Used:

-

Ray from Cool, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

4 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

pump and drive belt was thorn

Installed drive and pump belt.. very very simple. only tool required was a screw drive to remove front panel of the washing machine.

Parts Used:

-

Henry from KITTERY, ME

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

4 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

burning smell from washer

Replaced both the drive belt and pump belt in less than 10 minutes. Maytag has the easiest machines to work on.

Parts Used:

-

kevin from mundelein, IL

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

4 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

agitator did not move, all other functions OK

Removed the bottom belts to inspect. Belt for tub was well beyond it's service life. Belt for pump was OK. ordered the pair and replaced. When the washer was started the agitator still did not move. With power off I grabbed the agitator and pulled upward a few times then twisted it from side to side a few times. No change. Then I did the same with it with powered up ( a bit dangerous ). The agitator then ran OK.

Parts Used:

-

nicholas from white plains, NY

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:15 - 30 mins

4 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Overloaded my washer and broke the water-injector!

Had to look up how to pop the front panel off the washing machine - that was the hardest part. Once that was off, the top unbolted and the cover came off the back of the control panel with a few screws. Tilting the washer-top back, I was able to clip the new upper and lower injector (attached to each other in advance) to the washing machine. Then I realized that I needed to clamp the water line to the injector FIRST - so I found a small screw clamp and attached the water line. One screw and one plastic tab hold the injector in place. Everything went back together fine and worked great! Maytag washer keeps on truckin for another ten years!

Parts Used:

-

Richard from Coudersport, PA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

4 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

There was a burning rubber smell from the washer

I went to the Internet and saw how to pry the front panel off the washer. This gave me access to the two belts and four pulleys underneath the washer; a pair for the Drive and a pair for the Pump. There was enough slack in the original belts that they came off with minimal effort. The new belts were easy enough to install. It took a mere seconds to install the new Spacers on the Front panel of the cabinet. The most time consuming portion of the project was getting the washer turned out of its tight corner to get access to the clips on the bottom of the front panel.

Parts Used:

-

Steven M. from Fort Luderdale, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

washing machine very noisy took belt off pump and it was normal.

I tipped the washer up on 2by4 blocks used 1/4 inch rachet with 5/16 socket two remove 3 screws and the belt from underneath. Took clamps off hoses yahoo saved l00 bucks!

Parts Used:

-

Russell from Bayside, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

slow leak at bottom of unit.

This job turned out to be alot easier than I thought thanks to the tips I received on the web site. First I removed the agitator with a small nut drive I believe it was 1/4". Than I removed the two screws holding on the lid and lofted it out of the way. This is where the Hammer drill comes in. I had read someone else had used WD40 to help break free the threads and get the retaining ring off the tub it self. I worked on this for about 20 minutes with lube and trying to tap it off with the hammer and tap method. Finally I looked over and sitting there on the self next to the washer was my hammer drill. It can't be any worse than banging on the thing with the hammer. (They proably don't reccomend) but with a straight tip and a couple of quick shots the gaint nut came right off. I will say that my washer being older I could barely even tell where the threads were so I figured why not. It worked great. I then took the tub ring(plastic) at the top off and removed tub. Again a couple of quick shots with the hammer drill and the ring came right off. I did spend a little time making sure everything was clean and then reassembled machine with no more leaks. It may sound strange but it worked great with no fighting the space constraints, the calcium buildup and no damage to machine. If it doesn't work get a bigger hammer. Good luck

Parts Used:

-

alex from ogden, UT

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer was overfilling.

1. Disconnected washer from power outlet.

2. Slid washer out from wall to allow access to rear.

3. Isolated water supply and removed both hot and cold water supply hoses from solenoid valve assembly.

4. Removed one screw holding angled metal bracket with water solenoid valves attached.

5. Rotated bracket to get it to clear back of washer and expose wiring and fill hose.

6. Removed hose clamp on fill hose with pliers and then removed hose from valve assembly..

7. Removed wires from each solenoid.

8. Removed one screw that attaches solenoid valve assembly to angled metal bracket.

9. Slid valve assembly to allow it to be released from angled metal bracket.

10. Reversed procedure to install new valve assembly.

2. Slid washer out from wall to allow access to rear.

3. Isolated water supply and removed both hot and cold water supply hoses from solenoid valve assembly.

4. Removed one screw holding angled metal bracket with water solenoid valves attached.

5. Rotated bracket to get it to clear back of washer and expose wiring and fill hose.

6. Removed hose clamp on fill hose with pliers and then removed hose from valve assembly..

7. Removed wires from each solenoid.

8. Removed one screw that attaches solenoid valve assembly to angled metal bracket.

9. Slid valve assembly to allow it to be released from angled metal bracket.

10. Reversed procedure to install new valve assembly.

Parts Used:

-

Glenn from Lewisport, KY

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

All water into tub leaked from bottom of machine

To troubleshoot the problem I removed a panel/blank from the back of the machine. I then started to fill the tub while watching the pump. It immediately leaked from the shaft seal. I ordered the part early the next morning. It arrived late the next day. I was able to remove the front panel of the machine by removing a screw at each front corner of the bottom of the machine. The pump was attached with three screws which were simple to remove. The pump was an exact replacement and fit identically to the original. I tensioned the belt, and tested the machine. Before reinstalling the front cover, I cleaned the interior of the machine a bit and replaced a couple of hose clamps whose steel screws had started to corrode. All in all a simple repair.

Parts Used:

-

Steve from Martinsville, IN

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

water was leaking onto the floor

I removed the front of the washer (two screws) and found the drain hose to be cracked near the top where it attached to the drum. A hardware store hose was inadequate because it crimped when bent in an S shape as required, so I ordered the proper part amd installed with two new clamps.

I bought a 5/15 socket driver to do up the clamps, and all is fine.

I bought a 5/15 socket driver to do up the clamps, and all is fine.

Parts Used:

-

William from Tonka Bay, MN

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Pliers, Wrench (Adjustable)

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Water leaking out of the bottom of washer

Looked online and found a video for the repair consistent with a water leak. Two screws to remove the front panel of the washer, loosen two hose clamps, remove belt (by hand) and three screws to remove old water pump. Replaced pump, replaced belt (made sure it was tight, but not too tight), replaced water hoses, placed cover back on the front and I was done. Maybe 15 minutes tops. Very, very easy. Works like a charm and saved probably $100 in labor.

Parts Used:

-

Jacob from Coldwater, MI

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver, Screw drivers, Socket set

3 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

the pump belt broke

I tipped the washing machine (somewhat tricky since it sits under the dryer) and saw the broken belt. Went online, found the belt I needed, bought the set of two belts since I figured it would probably be a good idea to change both belts at the same time. After a few days I had the belts in hand; it took more time to jockey the machine back into place than it did to attach the belts. No tools necessary; the washer parts are on a spring. I did need a screwdriver, however, just to re-attach the washer's front panel.

Parts Used:

-

Jonathan from West Tisbury, MA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver

3 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!