GDG710 Maytag Dryer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Filter was old and ripped

-

Maurine from Bloomer, WI

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

73 of 134 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

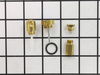

Gas Flame Would Drop Out

First it was a process of alimination to find out why it was dropping out. After the problem was found it was just a matter of replacing the holding coil on the gas valve. Thank you fred kenney sr

Parts Used:

-

FRED from BRIELLE, NJ

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

47 of 64 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Noise, possible low exhaust flow

1 Disconnect dryer from electrical outlet

2 remove vent pipe

3 Tilt dryer backwards and remove front cover bottom 2 philips screws.

4 remove lint assembly and then the fan blower housing with nut driver.

5 with pliers remove retainer clip from fan

6 remove snap ring with pliers or a flat blade screw driver will also work.

7 remove fan

at the same time I replaced the front glides if you do not want to do this then reinstall in reverse order and job is complete.

for glide replacement

1 remove the 4 screws holding the outer ring to the frame of the dryer.

2 drill out old rivits from the back side and then knock out. be careful to only drill rivit and not into metal frame

3 install new new glides makesure you install in correct direction.

4 install pop rivets with stud end on top side of glide. pushing rivet through glide and into the frame ring.

5 pop rivits and make sure they are secure.

6 reinstall ring making sure seal is around ring correctly

7 reintal 4 screws.

8 follow reassembly of blower and lint housing if you changed the fan. if not then just the lint assembly.

good luck the job is really easy and you will save yourself some money

2 remove vent pipe

3 Tilt dryer backwards and remove front cover bottom 2 philips screws.

4 remove lint assembly and then the fan blower housing with nut driver.

5 with pliers remove retainer clip from fan

6 remove snap ring with pliers or a flat blade screw driver will also work.

7 remove fan

at the same time I replaced the front glides if you do not want to do this then reinstall in reverse order and job is complete.

for glide replacement

1 remove the 4 screws holding the outer ring to the frame of the dryer.

2 drill out old rivits from the back side and then knock out. be careful to only drill rivit and not into metal frame

3 install new new glides makesure you install in correct direction.

4 install pop rivets with stud end on top side of glide. pushing rivet through glide and into the frame ring.

5 pop rivits and make sure they are secure.

6 reinstall ring making sure seal is around ring correctly

7 reintal 4 screws.

8 follow reassembly of blower and lint housing if you changed the fan. if not then just the lint assembly.

good luck the job is really easy and you will save yourself some money

Parts Used:

-

Joseph from Demotte, IN

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers

69 of 133 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

dryer would not dry clothes, no heat

I am a seventy year old recent widow, I have never repaired any appliance before. This was the first time I had ever seen the inside mechanisms of a dryer. I read the reviews on your site and followed the instructions of other do-it-yourselfers. However I could not locate the screws to remove the front of dryer. I would like to know if this dryer can be accessed through back of dryer, for future references. This is a 20 year old dryer, very well made, and I am reluctant to give it up. I think the job would have been much quicker and easier if the dryer front could be opened, as I would have also liked to check the main burner, valve, and belts, etc. for wear and if all was working efficently, as well as do a thorough cleaning. I did locate the igniter part through small door on bottom of dryer, I loosened the screw on igniter, unplugged small plug on wire harness and removed part. Ordered new igniter part and it arrived within less than three days, excellent service, as I live on the west coast. I replaced new igniter, turned on the gas, plugged in electrical cord, checked gas valve connection on back of dryer to make sure it was secure, turned on dryer and presto, heat, works just like new so far. A $25 part sure beats a $200 service repair or the cost of a new dryer.The repair job required about 45 minutes total time, most of that time spent trying to remove front of dryer. If a seventy year old woman beginner can do this, it should be a snap for most anyone else.

Parts Used:

-

Shelby from La Crescenta, CA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Socket set

36 of 39 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The light bulb was burned out and the Lens Cover was damaged.

The lens cover was easy to replace, but the bulb could not be extracted from the hole where the lens cover was (although it was indicated on the Internet that we could). We needed to get inside the dryer, but did not know how. I checked out a book from the library which told how to open the top dryer panel, but that way did not work. After a little more searching on the Internet, I was able to find a website that had FREE appliance repair manuals: http://www.appliancerepair.net/clothes-dryer-repair-5.html and that worked. It told us how to remove the FRONT panel. After removing the FRONT panel, not the TOP, I was able to replace the bulb easily. I was pleased to have been able to do this without calling a technician.

Parts Used:

-

Rose M. from Bradenton, FL

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers, Screw drivers

38 of 46 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The dryer drive belt broke. The dryer wouldn't tumble nor blow heated air.

The repair itself was pretty easy. Though I had figured out what needed to be done on my own while I waited for the belt to arrive via Fed Ex, the belt arrived with instructions that described the plan I had already figured and if I hadn't known what I was doing, the instructions would have been a great help.

STEP ONE, UNPLUG THE UNIT (and/or shut off the gas supply), CAREFULLY. Then, I took the front of the unit off by removing the 2 screws on the front panel near the bottom of the unit and disconnected the wiring that shuts the unit off when the door is opened. Set the front door panel aside. Then I removed the front of the tumbler retainer along with the exhaust duct and lint screen assembly by removing 4 screws that affixed the reatiner frame to the rest of the outer cabinet. Set this aside as well. Remove the entire tumbler unit. Set aside. Remove 4 screws on the back of the unit that hold the tensioner and motor access panel and remove it. Set it aside. At this point, I vacuumed every bit of lint and debris from the snapped belt out of the enitre unit, lubricated/greased all moving parts, cleaned off the friction bearing surfaces, and collected loose change ($1.35).

When the belt arrived, I unwrapped it, and placed the smooth side to the tumbler and rubber banded the slack off to the bottom right side (sort of the 4:30 position as you put the tumbler back into the unit). I carefully jimmied the tumbler back into the unit BEING CAREFUL not to pinch the groved belt between the tumbler and any other parts inside the cabinet. I replaced the tumbler retainer and screwed the 4 bolts back into place. I spun the tumbler over near the tensioner assembly (so I could see the slack through the access panel hole in the back) and removed the rubber band. I threaded the belt through the tensioner and over the drive pulley and rotated the tumbler clockwise to align the drive train of the belt. I plugged the 2 wires back into the switch on the inside of the door panel and then I replaced it on the front of the unit and screwed the 2 screws back in at the bottom front of the panel. I plugged the unit back in and tested opperation. It worked great! I unplugged the unit again (I'm not finished yet). I then replaced the access panel on the back of the unit and screwed the 4 screws back in. I moved the unit back against the wall and plugged it back in. Done! The dryer is less noisey now and more efficient most likely b/c I cleaned all the lint out of the thing! Thanks for the prompt shipment of the belt!! I'll get a few more years out of this dryer before spending $700 on a new one!!! Thanks again!

STEP ONE, UNPLUG THE UNIT (and/or shut off the gas supply), CAREFULLY. Then, I took the front of the unit off by removing the 2 screws on the front panel near the bottom of the unit and disconnected the wiring that shuts the unit off when the door is opened. Set the front door panel aside. Then I removed the front of the tumbler retainer along with the exhaust duct and lint screen assembly by removing 4 screws that affixed the reatiner frame to the rest of the outer cabinet. Set this aside as well. Remove the entire tumbler unit. Set aside. Remove 4 screws on the back of the unit that hold the tensioner and motor access panel and remove it. Set it aside. At this point, I vacuumed every bit of lint and debris from the snapped belt out of the enitre unit, lubricated/greased all moving parts, cleaned off the friction bearing surfaces, and collected loose change ($1.35).

When the belt arrived, I unwrapped it, and placed the smooth side to the tumbler and rubber banded the slack off to the bottom right side (sort of the 4:30 position as you put the tumbler back into the unit). I carefully jimmied the tumbler back into the unit BEING CAREFUL not to pinch the groved belt between the tumbler and any other parts inside the cabinet. I replaced the tumbler retainer and screwed the 4 bolts back into place. I spun the tumbler over near the tensioner assembly (so I could see the slack through the access panel hole in the back) and removed the rubber band. I threaded the belt through the tensioner and over the drive pulley and rotated the tumbler clockwise to align the drive train of the belt. I plugged the 2 wires back into the switch on the inside of the door panel and then I replaced it on the front of the unit and screwed the 2 screws back in at the bottom front of the panel. I plugged the unit back in and tested opperation. It worked great! I unplugged the unit again (I'm not finished yet). I then replaced the access panel on the back of the unit and screwed the 4 screws back in. I moved the unit back against the wall and plugged it back in. Done! The dryer is less noisey now and more efficient most likely b/c I cleaned all the lint out of the thing! Thanks for the prompt shipment of the belt!! I'll get a few more years out of this dryer before spending $700 on a new one!!! Thanks again!

Parts Used:

-

Lee from Royal Oak, MI

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers, Socket set

35 of 41 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer would light at start and then not light.

I used the trouble shooting part of this site and bought the radiant flame sensor and the high limit thermostat. Installation was very easy. The original problem still persisted and then purchased the temp. control thermostat, cycling thermostat and thermal fuse. These parts installed easily as well and the problem still existed.

While using the Multimeter to determine if the gas valve coils were getting voltage during the lighting process I moved the contacts on the two wire coil and noticed that the coil would activate sporadically. As it turned out the coil had a loose connection which would contact while cool and then lose contact when the coil warmed up.

This was a tricky issue to diagnose and am now waiting for a new coil to finish the repair.

I now have an almost complete set of spare parts for electrical issues and got them at a nice price. I will keep them in the event that I might need some of them in the future.

The repair would have been easy and very straight forward thanks to this website if the actual problem hadn't been the crazy heat related bad connection in the coil. Since the flame would light during startup the coils seemed to me to be good. Actually finding a weird issue is the sort of thing I find to be the fun part of repairing things.

Thanks Parts Select ! !

Gregg heagney

While using the Multimeter to determine if the gas valve coils were getting voltage during the lighting process I moved the contacts on the two wire coil and noticed that the coil would activate sporadically. As it turned out the coil had a loose connection which would contact while cool and then lose contact when the coil warmed up.

This was a tricky issue to diagnose and am now waiting for a new coil to finish the repair.

I now have an almost complete set of spare parts for electrical issues and got them at a nice price. I will keep them in the event that I might need some of them in the future.

The repair would have been easy and very straight forward thanks to this website if the actual problem hadn't been the crazy heat related bad connection in the coil. Since the flame would light during startup the coils seemed to me to be good. Actually finding a weird issue is the sort of thing I find to be the fun part of repairing things.

Thanks Parts Select ! !

Gregg heagney

Parts Used:

-

Gregg from Sedro Woolley, WA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

31 of 33 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Drum rubbing metal to metal on front support

1. Unplugged dryer, removed front (2 phillips screws near bottom) set aside with wires attached

2. Removed front support (4 hex head screws)

3. Drilled out pop-rivets, discarded old glides (why didn't Maytag use rollers?)

4. Riveted new glides in place.

5. (Oops!) trimmed cork pads, smeared with glue, shoved under glides, held down until firm

6. Removed drum (pushed belt back to groove, pulled drum off rollers, lifted belt off drum, worked drum out) Left belt on pulley and tension wheel as pattern when I replace it.

7. Scraped old gasket felt off back chassis and front support

8a. Folded gasket lengthwise and glued into front support channel with fold on outside diameter. It was too short.

8b. (Oops! Why didn't this come with instructions?) Pulled it out, reversed it and replaced it with fold to inside diameter. It fit. Glued ends together.

9. Glued other felt gasket into back chassis. (Good ventilation needed here!)

10. Replaced rollers. (This did have instructions, despite being easy. I didn't use any grease. Experience as a locksmith says don't lube anything that isn't sealed from dust. I also vacuumed out 15 years of dust.)

11. Replaced belt. (The old one looked fine, but I was advised to do the belt and rollers along with the glides.) The grooves touch the drive pulley, the flat goes around the tensioner, and the belt exiting to the left seems like it will rub the pulley, but it doesn't once the drum is installed.

12. Turn the drum around (Nice, it's symmetrical!) and work it back in.

13. Lift the belt around the drum edge (I used bull clips to hold it in place.)

14. Check the belt on the pulleys, move the drum in more, take off clips, move the belt to the groove.

15. put the drum on the rollers, lift the belt out of the groove, and spin the drum a little while watching the pulleys to check it.

16. Screw the front support back in place.

17. Screwed the front on and plugged it in.

It works!

2. Removed front support (4 hex head screws)

3. Drilled out pop-rivets, discarded old glides (why didn't Maytag use rollers?)

4. Riveted new glides in place.

5. (Oops!) trimmed cork pads, smeared with glue, shoved under glides, held down until firm

6. Removed drum (pushed belt back to groove, pulled drum off rollers, lifted belt off drum, worked drum out) Left belt on pulley and tension wheel as pattern when I replace it.

7. Scraped old gasket felt off back chassis and front support

8a. Folded gasket lengthwise and glued into front support channel with fold on outside diameter. It was too short.

8b. (Oops! Why didn't this come with instructions?) Pulled it out, reversed it and replaced it with fold to inside diameter. It fit. Glued ends together.

9. Glued other felt gasket into back chassis. (Good ventilation needed here!)

10. Replaced rollers. (This did have instructions, despite being easy. I didn't use any grease. Experience as a locksmith says don't lube anything that isn't sealed from dust. I also vacuumed out 15 years of dust.)

11. Replaced belt. (The old one looked fine, but I was advised to do the belt and rollers along with the glides.) The grooves touch the drive pulley, the flat goes around the tensioner, and the belt exiting to the left seems like it will rub the pulley, but it doesn't once the drum is installed.

12. Turn the drum around (Nice, it's symmetrical!) and work it back in.

13. Lift the belt around the drum edge (I used bull clips to hold it in place.)

14. Check the belt on the pulleys, move the drum in more, take off clips, move the belt to the groove.

15. put the drum on the rollers, lift the belt out of the groove, and spin the drum a little while watching the pulleys to check it.

16. Screw the front support back in place.

17. Screwed the front on and plugged it in.

It works!

Parts Used:

-

Jim from Los Angeles, CA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers

32 of 39 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer would not heat up.

I unplugged the dryer,removed the two small screws on the front of the dryer and pulled the bottom forward. The two wires connected to the door do not have to be removed. With an electrical tester using the Ohm setting I tested the Radiant sensor and the Gas Valve coils. The two terminal coil was DOA. The dryer can be operated with the front open as long as the door wires are connected. Symptons: The igniter would heat up and not release gas. My repair was successfull due to this awesome website and the super fast shipping service. AAAA++++

Parts Used:

-

Roger from Bonners Ferry, ID

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver, Screw drivers

26 of 29 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Rumble noise and groaning on startup.

I found that I replaced more parts than I needed to fix fhis problem. The source of the rumble was the blower wheel connection to the motor, allowing the wheel to wobble (plastic wheel flat spot worn off over time, no firm lock to the motor shaft). But the dryer should be good for another 10 years!

Disconnect dryer from electrical outlet and exhaust.

Remove the back access plate to release the belt from the pulley. Remove the two screws at the bottom front of the dryer, rotate the front to release it at the top. Remove the wires from the door status switch. Remove the 4 nuts holding the drum support frame and pull straight out. Remove the drum. Remove the two bolts holding the thermostat cover (silver odd shaped metal plate at the front of the dryer). Remove the dryer blower cover plate by removing the 6 bolts holding it to the blower housing. Remember to remove the bolt holding the plate to the bottom of the dryer. Release the door status wire from the clips on the left side of the dryer and set the blower housing plate to the right, out of your way without removing the wires. Remove the blower wheel by removing the Circlip at the front of the shaft and then removing the shaft compression clip. Pull out the blower wheel and then remove the rear Circlip from the motor shaft. The back of the blower housing can be removed by removing the 4 bolts holding it to the motor support frame to make access easier but this may not be necessary. Release the 5 wires attached to the motor. Release the front and back motor clips. I used a large straightblade scerwdriver to press down and out on the end of the clips. Lift out the motor. Remove the rear pulley from the motor using an allen wrench and transfer it to the new motor. Set the new motor in the support frame, ensuring the lips of the vibration isolation rings are pointed down to slip over the frame and are not facing up towards the clips ( makes clip instalaltion much easier). Hook up the wires, following the color coding on the motor controller you are attaching to. Reinstall the blower back housing if removed, rear circlip, blower wheel, front circlip, shaft compression clip, blower housing front cover (Including the bolt to the dryer bottom) , reroute the door switch wire up the left side, reinstall the thermostat cover, reinstall the drum and belt, reinstall the drum front support frame (ensure the felt seals for the drum and the blower cover are properly aligned and seated correctly), hook up the door status wire when your set the front cover and install the 2 screws, reinstall the belt through the pulley and idler wheel (make sure the belt smooth side is against the drum) through the back access panel and reinstall the panel.

Disconnect dryer from electrical outlet and exhaust.

Remove the back access plate to release the belt from the pulley. Remove the two screws at the bottom front of the dryer, rotate the front to release it at the top. Remove the wires from the door status switch. Remove the 4 nuts holding the drum support frame and pull straight out. Remove the drum. Remove the two bolts holding the thermostat cover (silver odd shaped metal plate at the front of the dryer). Remove the dryer blower cover plate by removing the 6 bolts holding it to the blower housing. Remember to remove the bolt holding the plate to the bottom of the dryer. Release the door status wire from the clips on the left side of the dryer and set the blower housing plate to the right, out of your way without removing the wires. Remove the blower wheel by removing the Circlip at the front of the shaft and then removing the shaft compression clip. Pull out the blower wheel and then remove the rear Circlip from the motor shaft. The back of the blower housing can be removed by removing the 4 bolts holding it to the motor support frame to make access easier but this may not be necessary. Release the 5 wires attached to the motor. Release the front and back motor clips. I used a large straightblade scerwdriver to press down and out on the end of the clips. Lift out the motor. Remove the rear pulley from the motor using an allen wrench and transfer it to the new motor. Set the new motor in the support frame, ensuring the lips of the vibration isolation rings are pointed down to slip over the frame and are not facing up towards the clips ( makes clip instalaltion much easier). Hook up the wires, following the color coding on the motor controller you are attaching to. Reinstall the blower back housing if removed, rear circlip, blower wheel, front circlip, shaft compression clip, blower housing front cover (Including the bolt to the dryer bottom) , reroute the door switch wire up the left side, reinstall the thermostat cover, reinstall the drum and belt, reinstall the drum front support frame (ensure the felt seals for the drum and the blower cover are properly aligned and seated correctly), hook up the door status wire when your set the front cover and install the 2 screws, reinstall the belt through the pulley and idler wheel (make sure the belt smooth side is against the drum) through the back access panel and reinstall the panel.

Parts Used:

-

Jeffrey from Bend, OR

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers

26 of 31 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dyer would not heat, flame would shut off within 10 seconds

I opened the panel, undid the plugs, detached the radiant sensor by undoing one screw and removed and replaced the part. Fairly simply.

Parts Used:

-

Christy from Riley, MI

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers, Socket set

24 of 29 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

the dryer was just getting warm at best

The dryer was not getting hot the clothes we're damp and had to put on hangers to finish drying. I pulled the cover plate saw the element was glowing the gas cable would kick on had a flame for about a four to six second count. I did some checking on the web. I read about others who were having same type of problem. Order the limit part and now.the flame stays on for about twenty second or less the dryer gets hot and it drys fast. Thanks for the web site. It took about thirty minutes . Now it works great.

Parts Used:

-

catherine from victorville, CA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

23 of 27 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Brand new dryer...needed to convert to propane.

I followed the directions that came with the conversion kit; which I ordered from PartSelect. Your website was the only place that could help me. Our new dryer is actually a Samsung. The people at Best Buy were no help. I called the Samsung headquarters and a "real" person there told me I could order from them or use a Whirlpool kit because they are the same. You guys were faster in getting me one, so I went with you. My wife was happy. I would recommend you to others.

Parts Used:

-

Timothy from Lawson, MO

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers, Wrench (Adjustable)

29 of 46 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Rattling sound.

Turned off circuit breaker. Removed two screws at base of front panel with stubby Phillips-head screwdriver. Swung panel up about 30-degrees, and removed panel, disconnecting red and yellow wire to door switch. Removed four sheet metal screws and took off large drum support bracket. Checked drum support rollers and shafts. They were fine. Reset circuit breaker and turned on dryer. Rattling noise still present.

Removed six small screws holding blower fan assembly. Shaft receiver on squirrel cage fan was worn completely round (it should fit onto a half-round shaft). Ordered new blower fan from PartSelect.com. Replaced tonight, and it works beautifully. This dryer is 29-years old. All it's ever needed in the 10-years I've owned it is a belt replacement and this repair. Long live the 1970s Maytags, and good parts suppliers like this one.

Removed six small screws holding blower fan assembly. Shaft receiver on squirrel cage fan was worn completely round (it should fit onto a half-round shaft). Ordered new blower fan from PartSelect.com. Replaced tonight, and it works beautifully. This dryer is 29-years old. All it's ever needed in the 10-years I've owned it is a belt replacement and this repair. Long live the 1970s Maytags, and good parts suppliers like this one.

Parts Used:

-

Laurence from Leesburg, VA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers, Socket set

21 of 24 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer was making awful noise during use

Removed the screws and took the door off then took the front panel off and popped up the top. Then pulled the drum out. Took snap ring pliers and removed rollers and replaced with new rollers then vacuumed all lint from machine and reversed operation to put everything back together. Operation was a total success!

Parts Used:

-

Pam from Aberdeen, WA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers

20 of 22 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!