DG312 Maytag Dryer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

the dryer was just getting warm at best

The dryer was not getting hot the clothes we're damp and had to put on hangers to finish drying. I pulled the cover plate saw the element was glowing the gas cable would kick on had a flame for about a four to six second count. I did some checking on the web. I read about others who were having same type of problem. Order the limit part and now.the flame stays on for about twenty second or less the dryer gets hot and it drys fast. Thanks for the web site. It took about thirty minutes . Now it works great.

Parts Used:

-

catherine from victorville, CA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

23 of 27 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

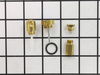

Brand new dryer...needed to convert to propane.

I followed the directions that came with the conversion kit; which I ordered from PartSelect. Your website was the only place that could help me. Our new dryer is actually a Samsung. The people at Best Buy were no help. I called the Samsung headquarters and a "real" person there told me I could order from them or use a Whirlpool kit because they are the same. You guys were faster in getting me one, so I went with you. My wife was happy. I would recommend you to others.

Parts Used:

-

Timothy from Lawson, MO

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers, Wrench (Adjustable)

29 of 46 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Rattling sound.

Turned off circuit breaker. Removed two screws at base of front panel with stubby Phillips-head screwdriver. Swung panel up about 30-degrees, and removed panel, disconnecting red and yellow wire to door switch. Removed four sheet metal screws and took off large drum support bracket. Checked drum support rollers and shafts. They were fine. Reset circuit breaker and turned on dryer. Rattling noise still present.

Removed six small screws holding blower fan assembly. Shaft receiver on squirrel cage fan was worn completely round (it should fit onto a half-round shaft). Ordered new blower fan from PartSelect.com. Replaced tonight, and it works beautifully. This dryer is 29-years old. All it's ever needed in the 10-years I've owned it is a belt replacement and this repair. Long live the 1970s Maytags, and good parts suppliers like this one.

Removed six small screws holding blower fan assembly. Shaft receiver on squirrel cage fan was worn completely round (it should fit onto a half-round shaft). Ordered new blower fan from PartSelect.com. Replaced tonight, and it works beautifully. This dryer is 29-years old. All it's ever needed in the 10-years I've owned it is a belt replacement and this repair. Long live the 1970s Maytags, and good parts suppliers like this one.

Parts Used:

-

Laurence from Leesburg, VA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers, Socket set

21 of 24 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Would not heat sometimes

Pulled the big front panel by removing two screws near bottom of front and pulling out at bottom until the top pops loose. Vacuumed out all of the dust and checked for loose connections. Ran dryer - igniter would light, but no gas. Checked the two solenoids with a VOM. the one with the two leads would intermittently read Infinity (open). Super simple repair. Remove two screws on solenoid bracket on top of the gas valve, Replace solenoid and plug it back in with the easy push-on connector. NO PROBLEM - all fixed.

Parts Used:

-

Chris from Laguna Niguel, CA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

21 of 25 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer was making awful noise during use

Removed the screws and took the door off then took the front panel off and popped up the top. Then pulled the drum out. Took snap ring pliers and removed rollers and replaced with new rollers then vacuumed all lint from machine and reversed operation to put everything back together. Operation was a total success!

Parts Used:

-

Pam from Aberdeen, WA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers

20 of 22 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Gas dryer runs, but no heat.

Unplug the dryer and remove the front panel (two screws at bottom of the panel), being careful of the door switch wires attached to the front panel. Using an ohm meter, I checked the ignitor for continuity and found it was open (should be 50-100 ohms). Make sure to check the solenoids on the gas valve. When the igniter goes bad, it will usually burn out the valve 1 solenoid boost coil (the one with 3 terminals), which was the case with my dryer. The solenoid coils are held in by a bracket with two screws (series 01 dryer) and are easy to remove and replace. Be careful replacing the igniter as the heating element is VERY fragile. Take the time to vacuum out all of the accumulated lint and dust inside the dryer while the front panel is removed, including the lint trap and duct. New igniter and boost/hold solenoid fixed the problem.

Parts Used:

-

Anthony from Merritt Island, FL

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set

21 of 25 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Replaced two parts in the gas heater assembly

I removed the front panel of the dryer by removing the 2 screw that secure it at the bottom and pulling upward to disconnect the cover at the top. I then removed the two screws that hold the metal cover that secures the 2 elements in place. I disconnected the wire plugs from the 2 elements, removed the 2 elements and replaced them with the new parts making sure to place them in the same positions as before. I then replaced the housing cover and tightened the screws. Then I replaced the front cover of the dryer.

Parts Used:

-

L R from Carmel, NY

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

20 of 26 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer wouldn't heat

I removed the front of the dryer by removing the two screws on the bottom of the front panel, disconnected the door switch wires. I removed the connectors from the coils on the gas valve, the heat sensor and the igniter. Loosened the gas line at the valve. I removed the screw holding the gas valve and burner assembly and removed the assembly from the dryer. Remover the screw holding the burner to the valve, and removed the igniter. Replaced the burned and reconnected what I had removed. The reason the burner didn't light was due to the gas deflectors being burned off of the burner, If the igniter, sensor, and coils check out OK , check the front of the burned to besure it is deflecting gas to the igniter

Parts Used:

-

Clarence from Vienna, IL

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Socket set, Wrench (Adjustable)

23 of 35 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Heat Would Not Come On

After replacing all the other fuses and sensors I finally replaced the Radiant Flame Sensor and it is working perfectly.

After replacing the other parts and the heat still not coming on I read somewhere that the Radiant Flame Sensor is a normal closed circuit and when I checked with a meter it was open. I would have saved a lot of time and money if I had read that earlier.

After replacing the other parts and the heat still not coming on I read somewhere that the Radiant Flame Sensor is a normal closed circuit and when I checked with a meter it was open. I would have saved a lot of time and money if I had read that earlier.

Parts Used:

-

Lynn from Novi, MI

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver

19 of 23 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Plastic grid was broken, brittle with heat and age

After unplugging the dryer, first I removed the two screws that hold the lower front of the dryer in place. Pulling the bottom out slowly releases the upper clips from the dryer top. I then removed the two wires for the door switch in order to move it out of the way. I then remover the four screws that hold the duct and grid to the front of the drum opening from the inside of the drum. I then simply put the new duct and grid assembly in place and replaced the four screws that hold it to the drum opening, replaced the wires to the door switch and replaced the front of the dryer.

Parts Used:

-

TERRY from GLASSBORO, NJ

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

18 of 22 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Loud rumble in dryer. Blower wheel broken.

First I unplugged the machine. I removed the two screws in the front panel and tilted the bottom of the panel out unclipping it at the top. I removed the lint duct whichis held in place with several 1/4" hex head screws. Then I removed the blower cover, also held on wth 1/4" hex head screws, exposing the blower wheel. Using snap ring pliers I removed the snap ring at the end of the motor shaft. Using needle nose liers I removed the spring clamp around the center hub of the old blower wheel and pull the blower wheel off the motor shaft. After cleaning as much lint out as I could I put the new blower wheel on the motor, secured with spring clamp and snap ring. Then I put the blower cover and lint duct back on and put front panel back on.

Parts Used:

-

Ernest from York, PA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers

16 of 17 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer was not heating

My 20 year old reliable Maytag 512 lgp dryer was not heating anymore. At first the heating element would glow red but not hot enough to ignite the gas. I replaced the element and it worked for a few loads but then stopped reigniting after the first cycle.

After some research and diagnosis (checking connections, amperage flow on each electriical part, etc.) I determined that the two coils were faulty. I ordered parts and replaced them (easy to do) and it worked again, for another few loads. Then nothing worked. The coil did not get hot and I did not hear the clicking sound that initiates current flow to the ignitor through the coils.

I checked the coils and ignitor again, they were fine. Frustrated, I called in a repairman to diagnose the problem. $55 and 15 min later he narrowed it down to the High Limit Thermostat. To demonstrate he bypassed the thermostat by directly connecting the two leads together and the ignitor fired right up.

His price to replace the thermostat? $45 part plus $130 labor. I bought the thermostat online for less than half his parts cost and the labor took me 5 minutes. Simply unscrew the small screws with a small socket set or nutdriver and replace the thermostat. Just two connectors, real simple.

All in all it was very easy to replace the parts, just tricky to diagnose unless you are good with electrical work.

After some research and diagnosis (checking connections, amperage flow on each electriical part, etc.) I determined that the two coils were faulty. I ordered parts and replaced them (easy to do) and it worked again, for another few loads. Then nothing worked. The coil did not get hot and I did not hear the clicking sound that initiates current flow to the ignitor through the coils.

I checked the coils and ignitor again, they were fine. Frustrated, I called in a repairman to diagnose the problem. $55 and 15 min later he narrowed it down to the High Limit Thermostat. To demonstrate he bypassed the thermostat by directly connecting the two leads together and the ignitor fired right up.

His price to replace the thermostat? $45 part plus $130 labor. I bought the thermostat online for less than half his parts cost and the labor took me 5 minutes. Simply unscrew the small screws with a small socket set or nutdriver and replace the thermostat. Just two connectors, real simple.

All in all it was very easy to replace the parts, just tricky to diagnose unless you are good with electrical work.

Parts Used:

-

Mitch from Sacramento, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver, Screw drivers, Wrench set

21 of 32 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Clothes were not drying, three hours still damp

Followed the instructions on the video, and saved 500 hundred dollars. I was already shopping for a new dryer. Thanks so much!

Parts Used:

-

STEVEN from BELLEROSE, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

16 of 17 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

converted gas dryer to LP

Instructions were great. Very step by step. It could not have been easier. Repair saved me a $100 service call.

Parts Used:

-

Bruce from Rogers, AR

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Pliers, Wrench (Adjustable)

16 of 18 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Original problem: Blower fan came loose from the motor shaft.belt and was making a noise clothes were slow drying. Second problem appear upon inspection: idler pulley bracket shaft severely worn.

Replacing the blower fan took way too long, like 4 hrs, because I didn't know how to disassemble the dryer and get to the problem. Replacing the idler bracket and assorted retaining rings and washers was fast, something like 1 hour. Disconnect the power cord, exhaust hose, and gas line. Remove two screws at the bottom of the face of the machine, unplug the electrical harness to the door light, switch and ground and remove the front of the machine. Remove the access panel at the back of the machine and remove the belt from the idler pulley. Remove the four screws holding the front drum support assembly and remove the drum. Replace some old retaining rings and the spring washers on the drum support rollers. Around back assemble the idler pulley assembly with some new washers and the old roller which seemed in good condition. Put it all back together. About one hour.

Parts Used:

-

adriel from sylmar, CA

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Wrench (Adjustable)

17 of 22 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!