SGR351CS0 Westinghouse Dryer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

dryer would turn for about 1min then stop

I replaced the rear bearing assy. Thanks to all that sent in there stories. very helpful. But my problem was the breaker in breaker box. needless to say "check your outlet for proper voltage.First,before anything else." i had a bad breaker, had it replaced,with proper 30amp fuses.Dryer works fantastic..Thanks to all again for your input. Great Website...

Parts Used:

-

James from Fort Worth, TX

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

2 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

temperature knob was broken

Just fix it in the groove and pushed it on and it was done in seconds

Parts Used:

-

Valerie from Moultonboro, NH

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

2 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

dryer knob cracked

-

NICOLE from KINGWOOD, WV

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

2 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

knobs broke

Just put them on. there wasnt any thing hard to do.

Parts Used:

-

CHANDA from BOGALUSA, LA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

2 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

No heat.

As others have described in more detail... I lifted the top, removed the 2 screws holding the front panel (one on each side, inside the control panel on either side - not the easiest to get at, but not too bad), popped the clips holding the front panel in place and removed it. With the front panel off, the location of the coils is obvious (lower left side). The only challenging aspect of this repair is that the 2 screws holding the coils in place are really torqued in so it was crucial to use the exactly correct size screwdriver and not let the screwdriver slip while unscrewing those screws. Actually swapping out the coils took seconds, of course they have to go in exactly the same way as the old ones. I did take a few minutes extra to vacuum out years of lint from the inside of the dryer. Overall, much easier and cheaper than I was expecting and now I know where everything is inside the cabinet.

Parts Used:

-

Steven from San Francisco, CA

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

2 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Making a squiking noise and letting lint into the cavity of the dryer

pulled appliance away from wall and unplugged the electrical cord and then used putty knife to pop up the top. Then removed the screws that held the front in place. Disconnected the wire to the switch on the door and then front on a rug and used acetone and scraper to remove the old glue and felt. Cleaned the area thoroughly and apply the glue that come with the kit an give it a couple of seconds to get tacky and then applied the felt and used clothes pins to hold in place for about an hour and then put back together and let it set over night before using. Had good success and it solved my problem.

Parts Used:

-

Robert from Rice Lake, WI

-

Difficulty Level:Really Easy

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers

2 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

broken knob

removed knob..very easy instructions..took 10 min...very pleased with repair and fast order...

Parts Used:

-

CLARK from JUNEAU, AK

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

2 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

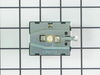

The start switch was broken

Took the front off the dryer and removed the old switch and put in the new one.

Parts Used:

-

Myrna from Apache Junction, AZ

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

2 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

read shaft and bearing wore out..screaching bad

I took the dryer apart to vacuum and check because of the screaching noise. Took drum out and found the bearing in pieces and shaft had rubbed against the brace. I thought as old as my dryer was I would never get a piece to fix it. I got online and found PartSelect.com. I found the part but could not tell if all was included. there was a Phone Number so I called it. I was helped instantly. They acted like it was no big deal to have a dryer that old. I got my part within a week and had my dryer back together. It works like new. Thank you

Parts Used:

-

rickey from richmond, MO

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Broken switch

Removed rear cover, unplug 2 spade connectors, twist out old switch, twistin new switch. plug connectors, install cover

Parts Used:

-

Richard from Yucca Valley, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

4 of 10 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Loud squealing

As all others have said, without being redundant, I'd view post #1 or #2 for a good detailed set of instructions.

The primary issue I had was with the stainless steel ball bearing that was shipped with the kit. I couldn't figure out what it was used for, because when I removed the bearing carrier the ball fell out before I could see where the original one was located. The stainless ball bearing is a grounding ball, not a bearing. It goes on the exterior of the plastic bearing carrier/receiver.

Once I figured that part out, it was a piece of cake.

Took a little longer than other people's repairs, but I also put a new belt on and re-worked the exhaust duct for solid ducting versus flexible duct. fine-tuning the rigid duct work was a piece of cake with the tumbler out, since i could crawl right inside the chassis and make sure everything would line up (level legs, adjust elbows, etc)

The primary issue I had was with the stainless steel ball bearing that was shipped with the kit. I couldn't figure out what it was used for, because when I removed the bearing carrier the ball fell out before I could see where the original one was located. The stainless ball bearing is a grounding ball, not a bearing. It goes on the exterior of the plastic bearing carrier/receiver.

Once I figured that part out, it was a piece of cake.

Took a little longer than other people's repairs, but I also put a new belt on and re-worked the exhaust duct for solid ducting versus flexible duct. fine-tuning the rigid duct work was a piece of cake with the tumbler out, since i could crawl right inside the chassis and make sure everything would line up (level legs, adjust elbows, etc)

Parts Used:

-

John from Avis, PA

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

plastic start knob stem broke off

First I unscrewed the back panel to be able to lift the cover off the control panel. I then removed the cover off the control panel and slid the knob into the locking tabs. I replaced the cover and screwed the back panel back into place.

Parts Used:

-

melissa from west chicago, IL

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

2 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Start Knob Broke

My wife simply removed the knob from the package and pushed it on. No tools were needed and she felt satisfaction that she was able to "fix" the problem on her own.

Parts Used:

-

Randall from Mount Horeb, WI

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

2 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Drum making noise when running ( rear bearing )

Took a putty knife and released top clips. Tipped top back , and took out 4 screws holding front cover in place. Lifted out drum, replaced bearing plate. Removed 2 screws and replaced back panel bearing. Placed drum back in place, installed front panel, snapped top back in place and job was done. Very easy. Took about one hour.

Parts Used:

-

Ralph from Wisconsin Rapids, WI

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

squeel when turning

lacked instructions. Internet yielded a simple paragraph. Scored real bonus when we discovered the lint build up past the internal filter was approaching catastropic level. Replaced the exhaust tube (plastic) with rigid metal and resolved to disassemble and clean dryer on 2 year cycle in future. Kit just isn't complete without detailed instructions. Parts were complete and sufficient. Local codes have eliminated the plactic exhaust tube. Recommend that all old installs refit to rigid or semirigid before the fire happens!

Parts Used:

-

Bob from Lynchburg, VA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers, Socket set

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!