KUCS03CTSS0 KitchenAid Trash Compactor - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Compactor piston stuck in down position and couldn't open!!!

First thing I did was put the unit on its side and removed the bottom to access the broken plastic gear that moves the chain that drives the compactor up and down...There I was able to manually move the chain by turning the nut with pliers and moving the piston up (painfully slow) until I could at least use the bin for trash while I waited for the replacement part to arrive. Once I had the part I loosened the four bolts that allowed the drive gear to move a little and slacken the chain - I then put in the new gear - make sure you have the proper spacing and washers - my replacement kit didn't have any washers so I resused the old washers and all seems to be working well!

Parts Used:

-

George from Houston, TX

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set

3 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

ram wouldn't go up or down.

pulled it out, turned it upside down, and removed the gear, then replaced it, turned it back up and pushed it back it worked.

Parts Used:

-

Mona from San Diego, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers, Wrench set

3 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

My very old trash compactor's carrier bag wore out

This new one from part select I think fit better than the original so all I had to do was install the handles as the depiction on the packaging showed and install it. Less than 1 minute.

Parts Used:

-

Jerry from CLARKSTON, WA

-

Difficulty Level:Very Easy

-

Total Repair Time:Less than 15 mins

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Bad gears and a bad switch

-

John from ALICE, TX

-

Difficulty Level:Very Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Wrench (Adjustable)

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

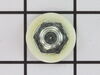

Roller was flat

Bought wrong roller. The drawer roller is different than the stationary rollers. Note the difference.

Parts Used:

-

John from Lancaster, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Wrench set

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Compactor draw was not opening fully as the wheel bearings had seized

I followed the you tube video instructions provided by customer care. This involved pulling the unit free from the cabinet, removing several screws that held the housing in place, this gave access to the wheel assembly, then I removed the nuts that held the wheel assembly in place. Fitting the new wheel assemblies was easy as was replacing the housing screws. After reinserting the draw and pushing the unit back into the cabinet it worked like new

Parts Used:

-

Andrew from ASHEVILLE, NC

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Socket set

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Plastic end piece broke.

Needle nose pliers pulled the end stuck inside. Installed new start switch knob.

Parts Used:

-

Brent from HUDSON, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

2 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Rotary switch had finally worn out and was brittle and broken on our 30 plus year old trash compactor.

Removed the switch knob, the outer nut, and the front plate.

Unplugged the old switch from the 3 wires and plugged them into the new switch and put it back together with the new knob. Probably less than 5 minutes.

Unplugged the old switch from the 3 wires and plugged them into the new switch and put it back together with the new knob. Probably less than 5 minutes.

Parts Used:

-

Ray from MUNCIE, IN

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers, Screw drivers

2 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

lost cover (went into trash)

-

Jacek M from Bedford, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

3 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Trash carier wore out

Upon the receipt of my part it just had to be slipped into place. I had the part I needed within 3 days of ordering.

My had ordered parts for various items in the past and we have always been very satisfied with the care and experteis of this company.

My had ordered parts for various items in the past and we have always been very satisfied with the care and experteis of this company.

Parts Used:

-

Carmen M from Port Orchard, WA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

2 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Compactor stop working

I flipped this unit over,removed 4 screws to the drive gear.I tore apart found a nut came off the screw rod.Which broke the drive gear.I looked on line found the parts select page.That showed the diagram i needed,to order parts, i needed.The wife and i tackled this task,of repairing this product.The repair was quick and easy.It took less than 30 minutes including cleanup.The wife happy,that all that matters.

Jack

Jack

Parts Used:

-

Jackie from Malone, NY

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Jammed KitchenAid Trash Compactor.

With nothing in the KitchenAid Instructions nor anything on the internet… I had to go it alone.

Actually quite simple… I laid the unit over on its front and removed the 5 screws holding on the bottom plate. This exposed the motor and drive train which turns the two compacting screws on each side. The main drive gear was broken.

Taking a wrench to the main drive… I was able to free up the jam… a piece of glass from a broken bottle.

I went to the internet and did a search on KitchenAid Trash Compactor Parts and discovered PartSelect.com… They had me enter the Model Number of my unit and a parts diagram and list came up… I found the gear I needed… ordered it and in two days it was here. Instructions came with the gear on replacement and in no time I was back in business.

I was impressed with the simplicity of KitchenAid’s Compactor, and the ease in which I was able to get my part from PartSelect.com!

Actually quite simple… I laid the unit over on its front and removed the 5 screws holding on the bottom plate. This exposed the motor and drive train which turns the two compacting screws on each side. The main drive gear was broken.

Taking a wrench to the main drive… I was able to free up the jam… a piece of glass from a broken bottle.

I went to the internet and did a search on KitchenAid Trash Compactor Parts and discovered PartSelect.com… They had me enter the Model Number of my unit and a parts diagram and list came up… I found the gear I needed… ordered it and in two days it was here. Instructions came with the gear on replacement and in no time I was back in business.

I was impressed with the simplicity of KitchenAid’s Compactor, and the ease in which I was able to get my part from PartSelect.com!

Parts Used:

-

Jan from Gilroy, CA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers, Wrench (Adjustable)

2 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Smelly kitchen

Removed the old filter and screen and replaced with the new!

Parts Used:

-

Saralyn from Dahlonega, GA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

2 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

none

-

craig from OCALA, FL

-

Difficulty Level:Very Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers, Socket set

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Front legs were rotted.

-

Cindie from DUNMORE, PA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Wrench (Adjustable), Wrench set

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!