JMP31BL1BB General Electric Range - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

F2 error message on my GE oven indicated need for new heat sensor

After unscrewing the old heat sensor from inside the oven, I pulled the range away from the wall, got behind it and removed the small panel over the heat sensor. Naturally, the plastic clips connecting the heat sensor to the range wiring wouldn't come apart, so I eventually had to simply pry them apart with two pliers. Then, naturally, the new plastic connector clip on the replacement part didn't match the clip from the range, so I had to cut off both receptacles and strip the wires, then used the provided wire nuts to make the connections. After that, it was easy, just secured the heat sensor inside the oven and replaced the panel. I didn't push the range back against the wall until I tested the repair. It worked fine!

Parts Used:

-

Joseph from Brick, NJ

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers

25 of 29 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Surface element indicator remained on.

The known problem: a short occured between the surface element and the INF switch. After replacing the wire between the surface element and INF switch. The surface indicator light remained on - indicating a power surge/spike. Prior to removing the old INF switch I disconnected the wires from the old switch one at a time and plugged each into the new switch terminals. Then I removed the knob from the front of the control panel and the 2 screws holding the old INF switch in place. Removed the old switch and replaced it with the new switch. Reinstalling the 2 screws and the knob. Surface indicator light was no longer illuminated and surface element works fine.

Parts Used:

-

Ed from Plymouth, MA

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

23 of 27 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

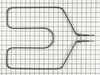

Replacement of heating element

If I'd had the Nut driver, it would have taken 15 -20 minutes or less. Went to Ace Hardware, bought the nut driver for $4.99.

Turn off the power at the box! Turn off the oven as well. Four screws total. Two to hold it in place and two that connect the element to the source.

First I removed the two screws that hold the element in place. I pulled the element out about 2 inches. Two more screws connect the element wires. I disconnected the element, threw it away, then connected the new element. I put the element in place, then replaced the screws that connect the power. Finally, I replaced the screws that hold the element in place.

Kimberly, El Cerrito, California

Turn off the power at the box! Turn off the oven as well. Four screws total. Two to hold it in place and two that connect the element to the source.

First I removed the two screws that hold the element in place. I pulled the element out about 2 inches. Two more screws connect the element wires. I disconnected the element, threw it away, then connected the new element. I put the element in place, then replaced the screws that connect the power. Finally, I replaced the screws that hold the element in place.

Kimberly, El Cerrito, California

Parts Used:

-

Kimberly from El Cerrito, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

16 of 16 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Oven stops heating and states F3 error code.

The most obbious suspect is the upper oven fan. Turned off power circuit breaker. Removed two philip screws at top of control panel and lowered the panel. Using the 3D view of the oven on this web site I located the fan limit switch. Jumpered the limit switch. Turned power on and the fan ran. That proved the switch was defective and not the fan. Replaced the limit I purchased from Partselect.com.

Please note* My life career was electrical. I used the schematic that came with the oven to determine that the limit was the only control between one of the 240 volt lines and the fan. Thus I knew it was safe to jump the limit.

If you are in doubt, seek some advice.

Good Luck, Arno

Please note* My life career was electrical. I used the schematic that came with the oven to determine that the limit was the only control between one of the 240 volt lines and the fan. Thus I knew it was safe to jump the limit.

If you are in doubt, seek some advice.

Good Luck, Arno

Parts Used:

-

Arno from Sacramento, CA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

19 of 26 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Convection oven fan and door light not working

The first step was to determine whether the problem was with the fan itself or the switch. I did this by opening the back cover and using a Volt meter to verify that the fan was not getting power. (I could have skipped this step.)

Next, I unplugged the range, closed up the back cover and lifted the range hood by removing two hex head screws that are just inside and on either side of the top of the opening in the range door. Propping the hood open, I removed the connector leading to the switch, then pushed the switch out the front. Inspection showed that the switch was damaged so I closed up the range and ordered the part from Part Select. Once the part arrived, it was a 15 minute job to unplug the range, lift the top, install the new switch, and close up the unit.

Caution. On starting to install the switch, I failed to unplug the range and my finger brushed one of the hot contacts leading to the switch. Thankfully, I was not injured. Do not repeat my mistake on this issue. Unplug the range even if you're only installing this simple switch.

Next, I unplugged the range, closed up the back cover and lifted the range hood by removing two hex head screws that are just inside and on either side of the top of the opening in the range door. Propping the hood open, I removed the connector leading to the switch, then pushed the switch out the front. Inspection showed that the switch was damaged so I closed up the range and ordered the part from Part Select. Once the part arrived, it was a 15 minute job to unplug the range, lift the top, install the new switch, and close up the unit.

Caution. On starting to install the switch, I failed to unplug the range and my finger brushed one of the hot contacts leading to the switch. Thankfully, I was not injured. Do not repeat my mistake on this issue. Unplug the range even if you're only installing this simple switch.

Parts Used:

-

Michael from Albuquerque, NM

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver

17 of 21 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The electric burner on the stove top would no longer heat up, when we removed it we noticed that the element was completely burned. I mean fryed!

First, I got my husband and let him know that the part was in (really easy), then I sat back and watched as he pulled the oven from the wall, unplugged it and lifted the stove top (so far, I haven't broken a sweat)! I then peeped up under the top as he removed a scew from the element and then several screws from the back panel, trace the wire to the needed element, and reconnect the new element (haven't broken a nail yet)! He then secured the element back on its mount, let down the top and plugged the oven back in, checked for accuracy...mission accomplished! This was the easiest repair I've ever done!

Parts Used:

-

Monica from Point Blank, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

14 of 15 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

oven would not cook over 325 degrees and sometimes would burn your food.

I removed the unit from the wall,removed the back panel to access the wires to the sensor,cut the plug off of the new sensor and strip the wires back,used the wire nuts to attach the new sensor,put all back together and slid back into the wall and works excellent.

Parts Used:

-

phil from forney, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

15 of 18 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

oven shut down code F3

As has been said shut down unit,Breaker fuse.If you do not have install info.Get a copy on line. If you have another set of hands it would not hurt.! this has been stated before. Remove door, Remove 4 screws , to slide unit out,I used a saw horse with some cribing secured to the horse to get height, Pull the oven out so that the two front supports are on the saw horse,and the back two are up to the edge runner.I used about a 1 ft stool for working height. Remove the top elec. cover sheet metal 2 screws. You will see were the wireing runs down the back. Get a small mirror,and flash light. Look down the wire opening in the back, you see the sensor connection ,I made a hook out of a coat hanger to grab it with. Pull it up before you disconnect it ,tie a piece of string to the sensor side of the connector , use 2 Ft. then disconnect remove two screws from inside the oven. And remove,sensor tie string on to new sensor connector pull through and connect.on top.Then replace everything cck every thing Twice!Doing this i didn"t have to pull the unit all the way out! LATER GOOD LUCK!

Parts Used:

-

Richard from Jupiter, FL

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers

17 of 24 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Broiler element would not heat; bake element did heat

Removed the oven racks, removed screws holding element hanging support from roof of oven, removed screws holding plate of element to rear of oven. CAREFULLY worked element loose from back of oven and gently alternated pulling each side of element (near the base) until connecting wires came free of insulating batting. Pull too hard and the connecting wires can break loose and disappear behind the batting. Once freed, disconnected both wires with socket (use pliers for extra grip on flat part of connectors, if necessary), removed element, braced new element on bottom of oven, aligning connectors to now-free wires. Re-attached with the new screws that came with the element (attachment points on element are threaded; do not reuse old screws as the threads may not match), gently re-inserted element into insulating batting at rear of oven, reattached hanging support, then replaced element plate screws.

Can be difficult to work in small, deep ovens....many oven doors can be removed. If so, remove oven door and use a chair as a support...lie on your back on the chair and hang your head and arms in the oven.

Can be difficult to work in small, deep ovens....many oven doors can be removed. If so, remove oven door and use a chair as a support...lie on your back on the chair and hang your head and arms in the oven.

Parts Used:

-

Brad from San Carlos, CA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Socket set

12 of 14 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Burner not heating

Originally the burner had a hole burnt through it, which resulted in a hole being burnt through the bottom of a pan. I replaced the burner and it would not heat up. I removed the top control panel, after securing power to the stove outlet, turned the power back on checked both sides of the swith with a meter (with the switch on) and had no power on one side. I went to two stores that did not have the switch in stock and ended up ordering from this site at about half the price! It arrived a couple of days later. I marked the wire colors on the old switch, took off the knob, removed two phillips head screws, pulled out the old switch and installed the new one and I was back in business. The hardest part was getting the sheet metal / heat gaurd positioned right upon re-assembly. To remove the panel there are two screws in the rear (nut driver) and a screw on either side of the front under each corner that require a torx driver to remove.

Parts Used:

-

jeffrey from geneva, FL

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver, Screw drivers

12 of 14 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Oven not heating

It was very easy I removed two screws unpluged the sensor and wire spliced it together and also replaced the modual on the top of the stove and it was that easy.

Parts Used:

-

Joseph from Stuart, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

14 of 21 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

infinate switch stem broke

took of the back panel with a nut driver,pulled off the wires one at a time ,put them on the new switch in same position as the old switch.removed old switch with a screwdriver ,screwed in new switch,replaced back panel,put on switch knob

Parts Used:

-

stephen from salem, OR

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

9 of 9 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Heating element dangling

-

Victor from Miami Beach, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

10 of 13 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Oven would not maintain set temperature

No problem installing oven sensor, but I diagnose the problem wrong, I need to change(ERC-11)control p/n wb27k5140

Parts Used:

-

Leonel from Biddeford, ME

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

11 of 16 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Burner went to "HI" after control knob turned past "MED"

Removed the screws holding the back in place, then pulled off the control knob and removed the two screws holding the infinity switch. Swapped the leads from the old to the new switch and reinstalled everything. Worked like a champ!

Parts Used:

-

Joel from Colorado Springs, CO

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers, Socket set

9 of 12 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!