DDC4407AHL General Electric Dryer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Dryer would not start and the smell of an electrical part burning.

What to do if you have a load of wet laundry at 23:00, the dryer won’t start, and you have no spare start switch.

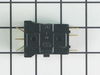

Removed rear access panel and discovered the wire from terminal #2 (goes to heater coils) on the start switch had melted and disconnected. The start switch showed signs of overheating but not melted. Removed the switch and found the switch’s actuator button was jammed in the ‘in’ position (dryer won't start). The switch was a friendly one in that it was possible to disassemble it. Most switches today are molded/glued together, but this one could be pried apart. The contacts inside were still in fair condition and, after dressing them, the switch was reassembled. The actuator button had a burr that was filed off and the switch action worked fine. All of the 1/4" male QC contacts on the switch were cleaned with a wire brush. The burned wire was cut back about 6” and a new piece of 14ga wire was spliced in with a wire nut. A new 1/4” QC terminal was crimped to the wire and all wires were re-attached to the switch.

This fix would probably last for a long time to come, but I bought a new switch and installed it and will keep the old switch as a backup.

p.s. The load of laundry was dry by 02:00.

Removed rear access panel and discovered the wire from terminal #2 (goes to heater coils) on the start switch had melted and disconnected. The start switch showed signs of overheating but not melted. Removed the switch and found the switch’s actuator button was jammed in the ‘in’ position (dryer won't start). The switch was a friendly one in that it was possible to disassemble it. Most switches today are molded/glued together, but this one could be pried apart. The contacts inside were still in fair condition and, after dressing them, the switch was reassembled. The actuator button had a burr that was filed off and the switch action worked fine. All of the 1/4" male QC contacts on the switch were cleaned with a wire brush. The burned wire was cut back about 6” and a new piece of 14ga wire was spliced in with a wire nut. A new 1/4” QC terminal was crimped to the wire and all wires were re-attached to the switch.

This fix would probably last for a long time to come, but I bought a new switch and installed it and will keep the old switch as a backup.

p.s. The load of laundry was dry by 02:00.

Parts Used:

-

Randy from FREMONT, CA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers

Was this instruction helpful to you?

Thank you for voting!

Dryer Completly Stopped Running

I have had this happen to another ge dryer, so I had an idea what was wrong. After taking the 4 torx screws out from under the front lip of dryer top, lifting the top back (like opening the hood of your car) in the back right corner is where the high limit tstat is. To verify the problem (dryer already unpluged of course) pull the two wires off the terminals of tstat, connect them together, wrap bare parts w/ electrical tape. Let top down & plug dryer in-- it started& ran fine. Got online and ordered replacement tstat (it arrived in 2 days-- great!) unscrewed the two 1/4" hex screws holding tstat on, installed new part. On to bigger and better things ! Dryer working fine.

Parts Used:

-

Ronald from Gatesville, TX

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver

Was this instruction helpful to you?

Thank you for voting!

dryer drum belt broke

The job is simple once you know how to remove the front panel. The steps are as follows:

1. disconnect the power cord.

2. remove 4 Phillips-head screws under the lip of the front panel that secure it to the top panel (#1 point Phillips-head screw driver)

3. swing the top panel up, it is hinged in the rear.

4. making note of the connection points of the color-coded wires, disconnect the wires to the lamp socket and door switch (I used a felt-tipped pen on the inside of the front panel to mark the connection points, "R" for red, etc.)

5. remove the upper 2 hex-head screws from inside of the front panel (5/16" nut-driver)

6. loosen the lower 2 hex-head screws (5/16" nut-driver) accessible from outside the panel (you only have to loosen them since the bottom mounting tabs are slotted)

7. slightly lift (to clear above mentioned lower tabs) and tilt the front panel toward you. Swing the front panel to the right as though you were opening a door and position so it does not fall.

8. remove 10 hex-head screws from the black lower rear access panel (5/16" nut-driver) and remove the broken drive belt. Note that the narrow black panel securing the power cable can remain in place.

9. at this point take advantage of the situation and vacuum out the years of lint and dust you could not reach before.

10. stand in front of the dryer, lift the dryer drum slightly and slip the new belt (rib side down) around the drum. Position the belt near the rear of the drum along the wear-mark left by the old belt.

11. go to the back and place the belt in the motor's drive-belt pulley, making sure the ribbed side of the belt mates with the ribs in the pulley.

12. position the tension wheel so that the it takes up the slack in the drive belt. Note the flat side of the drive belt will mate with the flat of the tension wheel.

13. spin the dryer drum a few turns by hand to make sure the drive belt lines up properly with the pulley.

14. reassemble the dryer by reversing the above steps, starting at step 8.

1. disconnect the power cord.

2. remove 4 Phillips-head screws under the lip of the front panel that secure it to the top panel (#1 point Phillips-head screw driver)

3. swing the top panel up, it is hinged in the rear.

4. making note of the connection points of the color-coded wires, disconnect the wires to the lamp socket and door switch (I used a felt-tipped pen on the inside of the front panel to mark the connection points, "R" for red, etc.)

5. remove the upper 2 hex-head screws from inside of the front panel (5/16" nut-driver)

6. loosen the lower 2 hex-head screws (5/16" nut-driver) accessible from outside the panel (you only have to loosen them since the bottom mounting tabs are slotted)

7. slightly lift (to clear above mentioned lower tabs) and tilt the front panel toward you. Swing the front panel to the right as though you were opening a door and position so it does not fall.

8. remove 10 hex-head screws from the black lower rear access panel (5/16" nut-driver) and remove the broken drive belt. Note that the narrow black panel securing the power cable can remain in place.

9. at this point take advantage of the situation and vacuum out the years of lint and dust you could not reach before.

10. stand in front of the dryer, lift the dryer drum slightly and slip the new belt (rib side down) around the drum. Position the belt near the rear of the drum along the wear-mark left by the old belt.

11. go to the back and place the belt in the motor's drive-belt pulley, making sure the ribbed side of the belt mates with the ribs in the pulley.

12. position the tension wheel so that the it takes up the slack in the drive belt. Note the flat side of the drive belt will mate with the flat of the tension wheel.

13. spin the dryer drum a few turns by hand to make sure the drive belt lines up properly with the pulley.

14. reassemble the dryer by reversing the above steps, starting at step 8.

Parts Used:

-

Adam from Colebrook, CT

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers

Was this instruction helpful to you?

Thank you for voting!

dryer making a squeeling sound.

It wasn't so bad taking it apart, but getting the drum back on was a problem. So what i did was too turn the dryer over and cut the heads off of three long screws and slid the drum over top of these and it lined up with the bearing housing.After a few tries it finally lined up and then i put the regular screws back in to hold the drum in place, one at a time.

Parts Used:

-

hobert from new park, PA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers

Was this instruction helpful to you?

Thank you for voting!

The dryer door wouldn't stay closed.

There is a plastic female closure part in the dryer door that wouldn't close tightly around the metal male closure on the dryer. I popped out the plastic square with a screwdriver, popped the new plastic closure in with my thumb. Works great. I never even installed the new metal portion of the latch.

Parts Used:

-

Jean from Waterford, MI

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

Was this instruction helpful to you?

Thank you for voting!

Dryer Squeeky

-

Elbert from LAWTEY, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

Was this instruction helpful to you?

Thank you for voting!

Loud Sqeaking noise

the replacement part was easy to replace but remembering how the belt went back on took alittle more time..

Parts Used:

-

Michell from Bellefontaine, OH

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

Was this instruction helpful to you?

Thank you for voting!

driver belt old worn out broke

The repair for the average untrained mechanicslly inclined " first off google directions/instruction picture step by step " we took off the wrong part which made this job difficult there is a part on the back that was removed prior to guided directions, called parts select they are awesome"our belt was delivered the next day on a 3 day weekend I was suprised second correct part sent anyone who took on this job , they will appreciatte all this . the belt was fairly easy to repair just do as directed follow guidelines. difficulty detaching a part that never should be"pain in the a" order your part from this company they rock" and picture guide and specific direction guideline @ this dryer has well outlived the money spent still kicking strong after several years of use hotpoint dryer

Parts Used:

-

Leland from San Diego, CA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers, Socket set

Was this instruction helpful to you?

Thank you for voting!