DCCB330GT0AC General Electric Dryer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

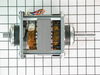

The main symptom was a burning smell that got on the clothes and the dryer was somewhat louder than it had been.

Researching on the web I thought the trouble might be lint buildup or trouble w/ one of the parts involved in spinning the drum. However I cleaned out all the lint and replaced the belt and idler pulley and this didn't improve the smell (drum bearing was fine). I then concluded the trouble was the motor. Running the motor w/o the drum in place confirmed this was where the noise/smell was coming from. Replacing the motor was fiddly--I had to remove the clip holding the motor (pried the top w/ a screwdriver), wires (made a diagram so as to put back in same order, they were hard to get off--a pliers did the job), clamps holding the motor on the duct, the motor mount, the duct, the fan. Putting all this back together took a while (not hard just fiddly). Tested the motor w/out the drum in place and it sounded fine. Put the drum and back/front/top panels back and the dryer runs fine now. All parts came quickly and exactly matched the parts in my 1993 Hotpoint dryer. As others have said the pulley kit is not needed--these are included w/ the motor. BTW I am a 53-year-old lady. Thanks to all who took the time to write up their experiences--big help!!

Parts Used:

-

Kristin from Bellevue, WA

-

Difficulty Level:Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Pliers, Screw drivers, Socket set

Was this instruction helpful to you?

Thank you for voting!

Loud Noises, Long time to dry

The dryer was making horribly loud sounds, and sometimes catching my clothes where the drum meets the door and messing them up. It was also taking a long time to dry. I ended up replacing the following parts: 1) FRONT DRUM BEARING, 2) THREE DRUM SLIDE BEARINGS, 3) AIR DUCT FELT SEAL, 4) REAR DRUM BEARING, 5) HEATER COIL (not the entire heater coil assembly ~$100, but the restring kit ~$15) 6) IDLER PULLEY WHEEL, 7) SEAL on AIR DUCT ASSEMBLY (just went to home depot and found a 3/8" foam seal with one sticky side in the section where home weather proofing stuff is). Everything is very easy to understand and complete for the 'occasional do-it-yourselfer'. The following things i would offer as advice to those attempting to do this: 1) Remember to remove the wires from the DOOR OPEN INDICATOR SWITCH before you try to pull off the front end. 2) Vaccuum all the lint out. Be diligent about the lint in the motor stuff, and the air duct fan. 3) The pully tensioner is tough to access. Removing and re installing the belt is challenging because you have to reach under the drum, into the machine 'blind'. It will help to have a pully diagram. The belt goes over the tensioned idler pulley before going around the right side of the drum (if you're standing looking at the front of the dryer). 4) There are tabs, which hold the electrical connectors in the bracket of the heater coil assembly. Having Strong needle nose pliers is reccomended. Also, it may be easier to bend the tabs down on the new heater coil if the heater when the heater coil peice is not attached to the back of the dryer, after the new coil is already restrung on the ceramic holders. Although there's only 3 wires for the heater coil, remember which wires go where. 4) The front drum bearing requires a surprising amount of force to remove and re install. Remember to take off the plastic felt seal tab on the side before you remove, and to put it back when youre done. 5) The screws in the back of the drum which hold the bearing slide on are tough to put back on since you need to reach through the drum and screw with one hand, while holding the piece in place on the back of the drum with the other. Having a helping hand there makes it easier.

Parts Used:

-

Chris from Bethlehem, PA

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers, Wrench set

Was this instruction helpful to you?

Thank you for voting!

Old filter was broken

-

Virgina from Toms River, NJ

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

Was this instruction helpful to you?

Thank you for voting!

broken door strike and latch

Parts arrived well in time, exactly what was needed. The latch was a snap-in process. The strike require gentile use of a pliers, and went in quickly. Thanks!

Parts Used:

-

Jonathan from Dultuh, GA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers

Was this instruction helpful to you?

Thank you for voting!

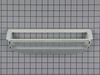

Lint Filter had holes in it

By hand, pull old out, put new in. I did not ask the question when I purchased the part so it arrived in a white color when my dryer is an almond color. I think the part store should expose colors to the next customer. Great job and very fast deliver.

Parts Used:

-

Helena from Newport News, VA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

Was this instruction helpful to you?

Thank you for voting!

lint screen was cracked and did not fit properly,the lint was not caught in the scree

removed the old lint screen, inserted the new one, if fit perfectly and it works just fine A quick,inexpensive repair that was easy to do

Parts Used:

-

Janet M. from Warwick, RI

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

Was this instruction helpful to you?

Thank you for voting!

Screeching while drying

After removing 14 million screws, finally got smart and looked on the internet to see how to open it up. It's super easy when you do it right! Ordered parts. Woman at PartSelect was patient and very helpful. My 15-yo son actually fixed it before I got home from work. His only question was where the green vs. white slide bearings go (the old part was badly worn, so we couldn't tell). He put the green on the "top" and the white on the "sides".

Parts Used:

-

Tim from Apex, NC

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

Was this instruction helpful to you?

Thank you for voting!