YKERS807SB02 General Electric Range - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

YouTube

-

Janet from GALLATIN, TN

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

2 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

blower noisy and slow to turn

First I looked at how I would get to the blower - this took 15 minutes. I removed the grills to access the burners. Then I removed the burners that took approx. 15 minutes. I then had to remove the knobs for the burners. Next I had to remove the front control panel which had 2 screws - (did not disconnect any wires but supported it). Next I had to remove the side trim. Next I removed 4-5 screws that secured the upper burner range top. Next I removed the side panels which has a braket on the lower forward side and 2 rear screws on each panel. Next I had to remove the aft backspash guard. At the back I had to remove a support braket that had several screws - then I had to remove the exhaust fan back panel guard. Next I had to remove approx. 7 screws on each side of the stove that supports the burner valves. Then I lifted the left side most closest to the blower. This gave me access just enough to remove the mounting screws (4) and to remove the 2 wires. There was some cushioning material which I found inadequate to prevent any vibration when the fan and the valve support top sits on the blower - so I doubled it. Then I reinstalled everything. This job took me 4 hours. I suggest calling a Kitchenaid repair technician and not doing this yourself. Unless you are a mechanically inclined and really like frustration.

Parts Used:

-

STEPHEN from CORAM, NY

-

Difficulty Level:Very Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Screw drivers, Socket set

3 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

cooktop cooling fan didn't operate

Pulled out stove and removed side panel, then removed old fan unit. Installed new fan unit and replaced side of stove then slide back in place, stove runs even more quiet than when it was new. And obtaining the new part from Partselect was even easier than dealing with a part store where you stand at the counter. This service really has the part down pat for us layman repair people.

Parts Used:

-

Wayne from Hillsdale,, MI

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers

3 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

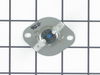

Oven wouldn't heat after a self clean mode.

After turning of the breaker for the oven, I pulled out the oven, removed the back panel. The High-Temp thermal cutoff was attached to 2 wires, which I unplugged, and then removed the cutoff by removing two screws. I then replaced the part in reverse order, pushed the oven back into the cabinet, and turned the breaker back on.

Parts Used:

-

Robert from Enola, AR

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

2 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

door hinges worn out oven door not fully closing

Remove and replace oven door hinges. Disassembly of oven door unit required. Step by step instructions available on youtube.

Parts Used:

-

Tony from HAYDEN, ID

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

4 of 9 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

bad burner

My dual zone burner would trip my breaker anytime i tried to turn it on. All the other burners would work fine. I searched online and found a way to test my burner, which was shorted or grounded out. I purchased a new burner from the site...It was as cheap or cheaper than other sites. It showed up a few days quicker than i was expecting..I also replaced the switch to the burner, just as a precaution and to save time since i already had the top glass off of my burners....EASY JOB!

Parts Used:

-

Krystal from Centralia, IL

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

R&R broken inner door glass and insulation.

Since there is multiple glass panels with several brackets, screws and insulation within the oven door I strongly suggest to take photos at each step using your smart phone. Do not attempt to remove all the components at once. Bracket positions, screw locations and glass orientation is necessary. This is the best advice I have to make this a quick and very easy job.

Parts Used:

-

Gary from PRESCOTT, AZ

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

2 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dual Surface Element went out

Followed the instructions in the video provided by PartSelect, which was very accurate. They only problem I have encountered is that the wiring from the old element compared to the new element do not match up 100%. I had to call Whirlpool today and schedule a Tech to come out and see if they can resolve the problem. Right now, when the burner is turned on, both the inner and outer elements turn on.

Parts Used:

-

Larry from RADCLIFF, KY

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Replace Broiler Element on a slide in range

Using the video from PartSelect I followed the steps shown. Sliding the range out was difficult so I tilted it forward resting the frame on a 5 gallon plastic bucket. I did have to crimp on a new terminal. The repair was straightforward.

Parts Used:

-

Richard from EUGENE, OR

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Broke the stem so the nob would no longer work

Turned the power power off. unscrewed two screws under the front face plate with the oven door open. Lifted up and over and the front face plate came off. Unscrewed the 2 screws hold the nob in place and disconnected the wires. Screwed the new one in place and connected the wires. Put the face plate back and turned the power back on.

Parts Used:

-

George from BELTSVILLE, MD

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Heat element needed replacing

Repair was really simple. Saw that the outer shielding on the existing heat element had degraded and ordered a new element. Part was shipped to my house in two days. Actually took me longer to get the oven door off than to replace the element because the left bracket on the door was slightly bent. Element came out after removing 4 screws and disconnecting 4 wire terminals. I was able to do the repair inside the oven and did not have to pull it away from the wall as the wires were long enough to pull through. I used some painter's tape to tape down the disconnected wires so they would not fall back behind the oven. Then I used a needle-nosed pliers to slightly crimp the wire terminal to the heat element and screwed in the four screws. That was it! Never did this type of repair before and it was really easy. Also estimate that for my 20-25 minutes of work I probably saved over $200 in parts and labor if I hired someone to do it.

Parts Used:

-

Michael from ARLINGTON HTS, IL

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The broiler unit needed to be replaced

I was stopped by the third screw on the roof of the oven, which was slightly rusted and would not budge in spite of using WD40! I had to enlist the aid of my son who arrived with better tools, including a SQUARE phillips head socket set. He also had to spend some time pinching and slightly reconfiguring one of the attachments in the back which did not slide together naturally. So, for an 82 year old retired housewife this was not as simple as it looked, but it was a piece of cake for guys like Erik with the know-how and the proper tools!

Parts Used:

-

Connie from SAN RAFAEL, CA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers, Socket set

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

burnt out element

good, used tie wire with a hooked end to fish one wire out of the back, to keep from removing the oven

Parts Used:

-

Bruce from ELKTON, OR

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Old dual burner lost one half. It appeared the metal strip that wound into and around the circle, broke right where it came into the inside of the entrance, and I wasn't about to try and break everything open to try and fix it, as it didn't look like soldering would be easy, or that it would fix it.

Verified via ohmmeter that one of the two burners was open and not working. I also tested the switch and that appeared to be working okay. I then took out the old unit and compared it to the new one, and found that they upgraded the new unit. I followed the instructions to match the labeled parts and move the wire to the newer location of that. i.e the old one had 2B and 2A at the top and 1B and 1A at the bottom. The new one had 2B and 1B at the top and 2A and 1A at the bottom. It did come with wire extenders and insulated tubes on top of them, and extra to cover additional. After a couple of tries, I decided which wire I needed to use on which (small connectors to match small, and large to match large.) In a second try I decided to flip it over to have it face up instead of down. Overall, it worked out very well, and I was very pleased when I did the power up test and everything worked as desired.

Parts Used:

-

Chris from WHEATON, IL

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Replace old Element

The new element wiring placements were totally different from the old element. Lucky for me the lettering printed on the terminals for each pole was the same as on the old one. It was just a matter of matching up each terminal pole lettering. The instructions that came with the new element were of no help at all. Youtube was my best helper.

Parts Used:

-

Patricia Josephine from N RICHLND HLS, TX

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!