WW30430P Jenn-Air Wall Oven - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Replace the oven Sensor

The sensor is mounted in the top right side of the oven.An extra long screw driver helps to avoid damage to the sensor when replacing it.The connectors were the opposite to the old sensor and I did not see that there were adapter cables included. It might help to connect or tie these together as I only expected the sensor and did not look for adapters.I had cut the wires and used wire nuts when I found the adapters.The repairs works fine.

Mike

Mike

Parts Used:

-

Michael from Exeter, NH

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Pliers, Screw drivers

3 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

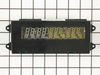

Oven Display Dim

After turning off the breaker, my husband removed the Oven Control Panel Cover. the Display assembly was connected with two multiple wire plugs. Once those were unplugged he plugged them into the new display assembly, reinstalled it, reinstalled the control panel. Turned hte breaker back on and HOORAY, after nearly a year with no oven display it still seem odd to beable to read the clock and oven temp!

Parts Used:

-

Caroline from Maineville, OH

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Socket set

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Door switch for oven light

1. Remove four screws on metal panel between top and lower oven doors. Pull the panel forward. You may need to open the top door partially to ease removal of panel.

2. Reach behind panel and unplug wire connector from old switch.

3. With panel free, squeeze ears on old switch and push through opening to remove.

4. Insert new switch in to hole and push from front to seat the switch. BE CAREFUL NOT to mess with the ears--if you try to splay them out (to better seat the switch) the switch will come apart.

5. Hold the panel up to opening to connect the wire harness to the switch.

6. Realign the metal plate to holes for screws and insert screws. (You may have to twist and turn to get the panel lined up.)

Done!

2. Reach behind panel and unplug wire connector from old switch.

3. With panel free, squeeze ears on old switch and push through opening to remove.

4. Insert new switch in to hole and push from front to seat the switch. BE CAREFUL NOT to mess with the ears--if you try to splay them out (to better seat the switch) the switch will come apart.

5. Hold the panel up to opening to connect the wire harness to the switch.

6. Realign the metal plate to holes for screws and insert screws. (You may have to twist and turn to get the panel lined up.)

Done!

Parts Used:

-

Sam from Garland, TX

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

3 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Door Lock Switch fell apart

My son removed the switch panel and unpluged

the switch. Then he replaced it with the new

switch fasten back the panel and turned the

power back on and everythiing worked fine.

the switch. Then he replaced it with the new

switch fasten back the panel and turned the

power back on and everythiing worked fine.

Parts Used:

-

Yvonne from Lake Odessa, MI

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Socket set

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

oven light glass cover was broken

took out the old dome cover and replaced it with a new one by unscrewing and replaced the new one and a fiberglass gasket. simple.

Parts Used:

-

wayne from LIMINGTON, ME

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Oven sensor caused cooling fan to run continuously. Had to flip breaker to get it to turn off..

Left oven off. Located sensor in pdf manual. Unscrewed mount, pulled sensor out to access connector. Disconnected old sensor, checked continuity(resistance) on ohms with multimeter. No continuity; connected new sensor, screwed mount back into place, turned on oven and baked cookies to check operation & it worked perfectly.

Parts Used:

-

Aubrey from EADS, TN

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

left cover for the oven light broke when trying to replace the bulb

Ordered the part. when it arrived-quite speedily, I just unpacked it and put the cotton gasket around the glass and screwed it to the proper place in the oven. Very easy.

Parts Used:

-

Mark from SHOREVIEW, MN

-

Difficulty Level:Very Easy

-

Total Repair Time:Less than 15 mins

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Oven erratic, not heating correctly, timer beeper sounding

The video indicating •unscrew old sensor, •pull wiring, •unplug old sensor, and •plug in replacement was good until I pulled the old one and saw wire nuts behind the small square hole! After some research, I learned that the nuts COULD come through that small hole with use of needle nose pliers. One of the wire nuts had the edges pinched off (chipped) in the process. Then I learned about ceramic wire nuts, which I'd never previously encountered. Very important if you don't want to melt your nuts! I cut and stripped the end of a disconnect plug to the stove wiring and now I have a plug in place; which, hopefully, I'll never need to use.

Parts Used:

-

Dave from SANTA BARBARA, CA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

bake element weakened in one spot and burned through

I removed two screws holding the element in place. Carefully pulled the element from its mounting throught insulation to expose the two wires connected by electric wire clips. I removed the clips and searched the part online using google. Part Select was provided as the top source. I ordered the part and it was delivered in two days. Taking care to thread the connection through the insulation, I was pleased to have installed it in about 5 minutes. All tools were still out and ready for use. Thank you for your service

Parts Used:

-

Paul from Woodward, IA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver

3 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The oven door slammed shut and the door lock switch broke causing the light to stay on continuously.

I contacted a local appliance repair store who didn't know what I was talking about. I looked online and the store called me back to tell me the part would probably be $75.00. I took the broken part out of the door frame and found the exact part online at your site, and ordered it for $14.00. Received the part within 2 days and put it in in 10 minutes.

Parts Used:

-

Lynne from Belchertown, MA

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

2 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Oven Temperature was 50 degrees low

Took screws out of the back on the side the sensor was on, unplugged it & took out the two screws on the inside of the oven to release the sensor. Put new sensor in place with the two screws & used one of the adapters to plug in the new sensor. Put screws back in the back panel & turned on the oven which unfortunately is still 50 degrees low. Need a new clock with computer which is out of stock & unavailable. I was an electrician for 25 years so didn't experience any problems. It was a cheap thing to try.

Parts Used:

-

Eugene from Clinton, IA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

2 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The lights in the clock/temperature assembly went dim and then eventually went out.

After turning off the power to the oven, I first removed four screws under the face of the control panel (open the oven door and look up). The entire front face of the control panel then slid out. I then unplugged the two sets of wires that led from that piece to the main oven (so that I could lay the front panel on the counter) taking care to remember where they would plug back in.

I then unplugged two wires from the clock assembly. Next, I unscrewed the clock assembly (an approx 3 inch by 5 inch assembly that is screwed to the very center of the control panel) using a small ratchet wrench set (they are hex screws). I then replaced the broken clock assembly with the new one, plugged it back in, plugged the front panel back into the oven, slid the panel back into place, and replaced the four screws. Turned back on the power. All done! 10-15 minutes.

Just take care to get the correct clock assembly for your model of Jenn-Air oven. There are several different versions that are not interchangeable.

I then unplugged two wires from the clock assembly. Next, I unscrewed the clock assembly (an approx 3 inch by 5 inch assembly that is screwed to the very center of the control panel) using a small ratchet wrench set (they are hex screws). I then replaced the broken clock assembly with the new one, plugged it back in, plugged the front panel back into the oven, slid the panel back into place, and replaced the four screws. Turned back on the power. All done! 10-15 minutes.

Just take care to get the correct clock assembly for your model of Jenn-Air oven. There are several different versions that are not interchangeable.

Parts Used:

-

Lisa from Shaver Lake, CA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Wrench set

2 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

I needed a broiler pan

I took the broiler pan out of the shipping container and put it in the oven.

Parts Used:

-

Rhoda P. from Secaucus, NJ

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

4 of 9 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Broken oven door hinge

I watched a You Tube video,removed and dismantled the door, installed the new hinge. I forgot to remove the small pin which is similar to a rivet. When I tried to close the door it bent. Eventually, I remembered the shipping pin and pulled it out with any damage. Believe it or not, I had read about the shipping pin on customer comments on PartsSelect...Good luck, it is relatively easy!

Parts Used:

-

Stephen from Monmouth, OR

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

2 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

No temperature control

Turned off breakers to oven. Removed two screws that held oven in cabinet. Removed oven door by opening slightly and pulling up on door. Pulled oven out 1/3 of way. Took out four screws on top of control panel. Took oven light switch off by unscrewing holding ring. Removed temp knob on right by pulling. Removed start / stop knob same way.Removed glass straight out. Removed four screws that held elecrtonic clock conrtol board. Unpluged three wire plug from right side and the nine wire plug from the left side. Worked board out at and angle. Went backwards to connect and replace board, screws and door.Slid oven back in and tested oven after turning breakers back on, worked like new.

Parts Used:

-

Max from Houston, TX

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

2 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!