WW27430P Jenn-Air Wall Oven - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Oven would not hold temperature, not turn on, and would shut off during use.

Extremely simple repair to make. Move stove away from wall and disconnect power. Remove the oven racks. Remove the rear sheet metal panel covering the wiring harnesses. Caution: Sharp edges and corners on sheet metal.Sensor is located in upper left corner on rear oven wall. Using a long-shafted #2 Philips screwdriver, remove the two Philips head screws and gently pull the sensor 1" away from the oven wall. At this point, it will help to have an assist from someone while you are behind the range. Have the assistant gently tug on the sensor while you watch for wires moving on the rear of the range. After locating the sensor wires, gently disconnect the plastic connector clip. Note: plastic connectors become brittle with age and exposure to heat Move to front of range and gently remove sensor from rear wall by pulling the wiring through the oven wall. Before inserting the new sensor wire through the oven wall, "dry fit" the wiring connectors to see that the new sensor is a correct connection. Make connection, and secure the sensor to the rear oven wall with the two screws. Install racks, reinstall rear sheet metal panel, and connect the power. Set the oven baking temperature to a moderately low temp, 300 - 350 deg. to test the new sensor.

Parts Used:

-

John from Arvada, CO

-

Difficulty Level:Very Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver, Screw drivers

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Needed replacement oven rack.

-

Bobby K. from Huntsville, TX

-

Difficulty Level:Very Easy

-

Total Repair Time:Less than 15 mins

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

No problem installing the sensor

I removed the two mounting screws and pulled the harness through the opening unsnapped the sensor from the harness and installed the new sensor i didn't have to used the adapters the new sensor fitted

Parts Used:

-

tommy from FAYETTEVILLE, NC

-

Difficulty Level:Very Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

F5 fault code kept appearing

I installed the new oven sensor but the problem continued. So I ordered a new relay board and installed it. Still no luck. So I pulled the new board back out and started trouble shooting it using my electronic background. I discovered the new board was using a pin for L2 that had no exit on the backplane, so I removed it and installed it where I believed it should go. Reinstalled the power relay board and presto. My oven is working lie a champ. Louis

Parts Used:

-

Louis Rodriguez from Granbury, TX

-

Difficulty Level:Very Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Screw drivers

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Maytag range had "F3" code display, oven would not work.

Oven sensor replacement was easy. Thermistor was installed in less than 15 minutes. After installation STILL had "F3" error message. Harness was ok, "Clock" or ECU needed to be replaced. "Computer" is obsolete, no spares available, some companies will rebuilt for $400+. Since the stove was going to the landfill I had nothing to lose by taking the "Clock" apart. It has one chip that is probably the power supply and control chip, another chip is an EEPROM with 128 bytes of storage and the last is a darlington chip that controls the relays. Cleaned up everything that looked like it needed cleaning with alcohol. When I reassembled the unit the pins for the thermistor harness felt loose, so I took it apart, again, and found cold solder joints on all four pins. It must have been there all along but plugging and unplugging the harness finally broke out the solder so I could see it. Soldered the pins back in and now it all works. It's worth a try if you're getting the "F3" message. If the relays on your stove aren't working it would be a good idea to replace the darlington chip. Good luck.

Parts Used:

-

phillip from Farmington, NM

-

Difficulty Level:Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Screw drivers

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The lower and upper circuit boards were blown do to a power surge

Shut of power to unit, removed front display panel, located lower circuit board. Removed the one screw holding existing board and installed new board, then swaped wires from damaged to new. re-installed front panel, turned pwoer back on, that was it. The unit is working well.

Parts Used:

-

Eugene from Marion, MA

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

4 of 11 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Oven would not heat

Flipped off breaker and removed oven door and pulled built in stove out so the back panel could be removed. Unplugged the sensor then removed the two screws securing the old sensor inside the oven and installed new sensor. Put stove back together and installed back into counter top, re-installed oven door, flipped on the breaker and oven works like new.

Parts Used:

-

Ralph from Nicholasville, KY

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

1 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Top oven element works, but bottom element works only intermittently

Replaced the long Oven Sensor but have not resolved the root problem. Oven still will not reach required temperature. Bottom element becomes red hot, but turns off and will not start again.

Parts Used:

-

Bruce from Glencoe, MN

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

2 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Oven not heating to desired temp

Had to remove oven from mounting cabinet to get to the back since the wire lenght to the conector was to short to come through the mounting hole.

Other than that the repair was straight forward. 4 screws to dismount the Oven from cabinet, 2 screws to remove Sensor and 3 srews to open the back of the oven once out in the open. New cable adapter that came with the new sensor was needed in my case.

Other than that the repair was straight forward. 4 screws to dismount the Oven from cabinet, 2 screws to remove Sensor and 3 srews to open the back of the oven once out in the open. New cable adapter that came with the new sensor was needed in my case.

Parts Used:

-

Raymond from Ridgecrest, CA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers

2 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Burnt oven heating element

Ordered part on line, part came within few days well wrapped and protected, very simple repair removed two mounting screws and two lead wires to remove burnt element, replaced with new one, wire were re-connected and the mounting screws secured the new element in place, about 20 min job.

Parts Used:

-

Fadi from Wilmington, OH

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver

1 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

After doing an oven self clean cycle, oven temp couldnt be set correctly, heat element was warm,not hot

After trying to set the bake temp after the self cleaning, it would not heat up. I Googled the model number,selected your link because it mentioned my symptom,and said usually it is the temp sensor in the oven that gets damaged by the high self cleaning heat. Your site had a place to enter my model number. You provided a great exploded view of the parts, showing me my sensor,then you provided the part number of the kit i needed,and filled out the order form with payment method. Less than a week later I got my part with instructions. Your video showed me the two screws I remove from the front ,and I pulled the old part out and uplugged it's connector. Replacement was easy, and oven was fixed! Thank you for a great site! You held my hand through it all!

Parts Used:

-

Philip from Winter Haven, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

1 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Oven Over Heating

Removed the oven from the wall. Removed back cover and unplugged sensor from the harness. Remove and replace sensor from inside the oven. Reconnect harness and reinstall back cover. Secure oven back into the wall.

Parts Used:

-

Steve from New Albany, OH

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

1 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

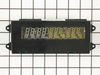

Replaced Clock/Control LED

Removed the metal panel, approx 5 screws, removed LED approx 4 screws and a few electronic connecters. very easy saved $100's vs calling a repair person

Parts Used:

-

Laura from Wisconsin Rapids, WI

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

1 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

This display light was virtually invisable and both doors on the double wall oven had trouble opening and closing.

I removed the control panel to replace the electronic clock and and was very simple. Remove the screws beneath the assembly, then lift if off the flange at the top. If you have a cabinet door above, you may need to remove the door to provide enough space to lift up and remove the assembly from the flange. The other posts really helped in understanding how to remove the old clock assembly - only word of caution concerns the removal of the black electronic contact wire strip - you need to lift up on two small tabs on each side and it slips out easily.

The over door hinge assebly is described well in prior posts and is very simple. If you are replacing your hinges, just do all of them as I found they were all suffering from fatigue. Remember to place a small nail in the hole in the hinge to prevent the old hinge from snapping when you remove it. When you inspect you new hinge, you'll see they've placed a temporary piece in the hinge assembly so you can slide it into the holder on a slight angle. Then replace the screw and backet that holds the hinge in place. When complete, open the oven fully and remove the small metal piece so the hinge can close completely.

One post mentioned the need to replace the hinge post on the side of the oven that holds the hinge in place on the oven. I opted not to do this and the new hinges work perfectly without getting involved in removing this part.

I found this entire experience easy and efficient - for just over $200, we have a control display that we can see and two oven doors that open and close easily!

The over door hinge assebly is described well in prior posts and is very simple. If you are replacing your hinges, just do all of them as I found they were all suffering from fatigue. Remember to place a small nail in the hole in the hinge to prevent the old hinge from snapping when you remove it. When you inspect you new hinge, you'll see they've placed a temporary piece in the hinge assembly so you can slide it into the holder on a slight angle. Then replace the screw and backet that holds the hinge in place. When complete, open the oven fully and remove the small metal piece so the hinge can close completely.

One post mentioned the need to replace the hinge post on the side of the oven that holds the hinge in place on the oven. I opted not to do this and the new hinges work perfectly without getting involved in removing this part.

I found this entire experience easy and efficient - for just over $200, we have a control display that we can see and two oven doors that open and close easily!

Parts Used:

-

Brian from Elkridge, MD

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

1 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Display faded to unreadable

Switch off the breaker to the oven. Unscrew the 3 top and 4 bottom screws holding on the control panel cover. Unplug the 2 cables from the clock assembly (which run to the oven). Remove the 4 hex screws which attach the clock assembly to the control panel cover. Unplug the ribbon which attaches the clock assembly to the control panel cover by lifting the black tabs and sliding it out (there is not a plug on the end of the ribbon). Switch out the old clock assembly for the new one, reverse the steps to put it back together.

Parts Used:

-

david from Los Angeles, CA

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver, Screw drivers

1 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!