WTW7990XG1 Whirlpool Washer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Unlevel code. Would not complete spin cycle.

First replaced four basket spring supports. Next tried Basket hub assembly ( which showed wear, but not total solution). Next replaced the rotation sensor that's on the stator. That finalized the issue.

Parts Used:

-

Robert from MORGANTON, GA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set

9 of 11 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Error reading 5D - wouldn't spin

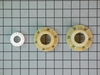

3rd time replacing this part. The plastic grooves against the metal get wore down. Only 20$ to repair ! Take off the 3/8 bolt - center pops out. Remove screws pop out old piece and tighten new piece each side evenly.

Parts Used:

-

Theresa from WALFORD, IA

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers, Screw drivers

9 of 12 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Suspension rod snapped, tub tilted severely and resting against metal cabinet, load unbalanced error

My problem stemmed from a previous leaky bleach dispenser hose (repaired over a year ago). It had leaked just above suspension rod assembly (only 1 of 4 was effected).Rod had rusted to point where it snapped just below the top mount. This actually made the replacement very easy as the rod simply slid out of the bottom tub channel and onto floor when washer tilted 45 degrees. Before tilting washer, unplug washer and disconnect supply lines and drain hos Use pry bar to separate cabinet top from cabinet lower section. Tilt top section to grant accesses to top suspension rod retainer mounts. Remove black rubber retainer washer from new suspension rod. As assistant holds tilted washer, a new suspension rod can be pushed thru bottom tub channel. Place black rubber washer back onto suspension rod. This will prevent the new rod from sliding full back out tub channel when released. The purchased suspension item has four rods and four top retainers. I could have reused the old retainer, but would have been more difficult to release the remaining rusted rod bit. So pulling up on rod and twisting suspension rod such that rod hook end pass thru top cabinet retainer cup and slides into position on new rod hook end retainer. Release retainer and rod, and move tub side to side allowing retain to assume natural position. (reference the other 3 retainers). Realign mating surfaces of cabinet top and cabinet lower if needed. Close cabinet top onto cabinet lower. Connect supply lines and drain hose, Plug unit in. Repair complete.

Parts Used:

-

Jeffrey from Roanoke, VA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

7 of 8 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Whirlpool cabrio would not go into the spin function without triggering an error code of 5d

Removed the center cover of the agitator with a flathead. Removed the nut of the agitator main cover. Had trouble taking the cover off because of the crud holding it down I wiggled it up gently alternating n,s and e,w until I eventually saw it separating from the bottom of the basket. Once it came off you could see how nasty the old hub assembly looked. Took the screws off the old hub assembly and removed it. Matched it up with the correct new hub assembly cause the kit comes with 2. Cleaned the shaft and that general area. Installed the new hub assembly, replaced the covers. Ran the drain and spin cycle and it worked with no problem. There are videos on YouTube that show you too. DO NOT try to pry the agitator cover if it won’t rise up easily. Be patient and it will come out.

Parts Used:

-

Victor from HOUSTON, TX

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set

5 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

F51 error code

Pretty easy! Just follow this link on how to fix the problem:

https://www.youtube.com/watch?v=_-Hg8rLGiKQ

The hardest part on fixing this is trying to move the washer out of its place so I can tilt it to see underneath the washer where the repair would be.

https://www.youtube.com/watch?v=_-Hg8rLGiKQ

The hardest part on fixing this is trying to move the washer out of its place so I can tilt it to see underneath the washer where the repair would be.

Parts Used:

-

Edgardo from SALEM, OR

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers, Socket set

5 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer making lot of noise during spin cycles

Removed agitator and basket hub parts and cleaned all parts of agitator then replace basket hub with new basket hub kit according to video ran washer but did not solve problem

Parts Used:

-

Michael from SAVANNAH, MO

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Socket set

6 of 9 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Cracked housing

Turn off and unscrew hot -cold hoses and drain line. Unplug power and pull unit away from wall. Tip onto front of machine and lean it onto something that will give you enough room to work as the pump is on bottom left back of unit. Unscrew all back plate screw's and remove back panel and keep screw's handy. Three main screw's hold pump in place but loosen hose clamp's first and its out. Reverse what you just did and you should be good to go! Good Luck!!

Parts Used:

-

John from Durango, CO

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Pliers, Screw drivers

4 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Leaking water inlet hoses.

-

Helen from NASHUA, NH

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

4 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

water leaking under washer

removed back of washer. turned washer on its side .removed the 3 screws holding pump and the 2 hoses and the electric connection pump came right out. did the reverse to install the new one.stood up the washer and ran it to check for leaks.no leaks installed back of washerand done

Parts Used:

-

Scott from Wyckoff, NJ

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Pliers

4 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

A leaking water pump

Have the Maytag washing machine little over2 years and the water pump cracked - very disappointed.

Anyway, removed the back panel, unhooked the hoses, used 5/16 wrench to loosen up the screws, unplugged the power connector than replaced it with a new water pump.

It was an easy repair that I taught my 18 yrs old.

Anyway, removed the back panel, unhooked the hoses, used 5/16 wrench to loosen up the screws, unplugged the power connector than replaced it with a new water pump.

It was an easy repair that I taught my 18 yrs old.

Parts Used:

-

Connie from Woodland, CA

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver, Socket set

4 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Noisy during spin cycle

Repair was pretty straight forward with the exception of removing the agitator. Hint, do not force it, just continue to work it until it releases. Problem was not entirely corrected, but improved.

Parts Used:

-

Robert from ORLANDO, FL

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Stripped screws on a hub drive replacement

Getting to the actual hub is a bit difficult as it involves removing the accetuator and takes some time and patience, but when I tried to replace with a new hub, I found that the screws were stripped, so PartSelect walked me through the ordering process and helped me choose the exact size screws that I needed. Parts came quickly...I already had the hub waiting to be secured and the screws tightened easily. (We had tried using a similar size, but you REALLY need the whirlpool screws that go in there) No more spinning problems, and the machine is not jumping around anymore. Works just like before. This particular machine has to have this part replaced at least twice a year (luckily it's cheap),but saves us from having to buy a whole new machine. My son also told me that since I replace the part so often, best to replace the screws every other time as well.

Parts Used:

-

Bruce from GLOBE, AZ

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Loud banging during wash cycle

This is an easy one. Snap off the agitator cap with a screwdriver.

Remove the single but and agitator.

Remove 6 phillips head screws.

Lubricate the bearing and coax it off the spindle.

Remove the single but and agitator.

Remove 6 phillips head screws.

Lubricate the bearing and coax it off the spindle.

Parts Used:

-

HARRY from BEND, OR

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Socket set

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Changed out suspension springs

-

John from NEWPORT BEACH, CA

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers

2 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

"dL" error code on display. Lid lock mechanism not working.

This was the second time I did this repair, so it looks like this mechanism lasts about 3 years. I found the video instructions on your website very helpful, with one major exception. On my Maytag Bravos XL machine, there are no clips on the front of the top plate to release by pushing in a putty knife. Rather, there are two vertical brackets on the back of the top plate that are loosened or removed, and then the top can be slid forward about an inch and lifted up.

Also, the tiny electrical connection plugs are secured by plastic clips on the sides of the receptacles. Those clips just need to be spread apart a little in order to unplug the connectors; i.e., don't pull too hard on those plugs, or look for a release lever on the plugs themselves.

Repair is straight-forward. Thanks!

Also, the tiny electrical connection plugs are secured by plastic clips on the sides of the receptacles. Those clips just need to be spread apart a little in order to unplug the connectors; i.e., don't pull too hard on those plugs, or look for a release lever on the plugs themselves.

Repair is straight-forward. Thanks!

Parts Used:

-

Bruce from WOODSTOCK, CT

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

2 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!