R200 Jenn-Air Cooktop - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

New Drip Bowls

I have bought several drip bowls over the years. They all seemed to not fit just right. These are perfect! Thanks!

Parts Used:

-

John from San Antonio, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

9 of 11 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

burner receptacle burned out

Worst part of the job was removing the old screws that held the two old rectecles in place for the two burners I repaired. Once the screws were removed cut the wires stripped them and used the porceliean wire nuts provided with the kit. Easy job and good instructions.

Parts Used:

-

Michael from N. Haverhill, NH

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

8 of 9 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

knobs were old could not read numbers

-

catherine from holland, MA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

8 of 10 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Both the 8'' burner and the vent fan didn't work.

1st-turned off breaker, 2nd- took out the two screws that hold the control panel and lifted it up so I could remove the surface unit switch,3rd- removed wires from old switch and securing nut and removed old switch,4th- installed new switch and plugged in wires, then turned on breaker to see if burner would work and it did. 5th-turned off breaker again and removed the wires from the fan switch and used nut driver to remove retainer nuts,6th-installed new fan switch and plugged in wires, 7th- put control console back in place and the two screws that hold it in place. Turned breaker back on and everything worked.Didn't use the burner receptacle or burner.

Parts Used:

-

Walter from N. Richland Hills, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers, Wrench (Adjustable)

9 of 14 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Switches were worn out (2) and shorting out. Throwing the breaker. Actually I think the ladies boyfriend/ fiance' tried to replace the knobs that were broken with universal knobs. They didn't fit so he forced them and broke the switches internally.

Shut off the breaker! Removed down draft grill. Removed two phillips head screws and lifited switch plate out. Removed switches (2) and made wiring diagram as I went. Looked up Jenn-Air on line and ordered parts. Lost wirihng diagram in the process but still had two switches wired . Replaced all four switches. Everything working great. However while I was waiting on switches to arrive, somebody at the house was fooling with the switch plate and broke the on red indicater lens so now I'm ordering that. Oh well....

Parts Used:

-

Jerry from Midland, TX

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Wrench set

6 of 8 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Burner temperature control did not work.

Got a no-name tailor-it-yourself replacement switch from a San Jose, CA appliance parts store; but the switch was so cheaply made that it fell apart when I tested it.

Got a RobertShaw part from PartSelect and now the burner works perfectly.

Got a RobertShaw part from PartSelect and now the burner works perfectly.

Parts Used:

-

Gerald from Palo Alto, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers, Screw drivers, Wrench (Adjustable)

5 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Burner would n.ot het hot

We unscrewed the top plate, unscrewed the top of the switch removed the ballast underneath and it worked. I was so glad to be able to still get the parts.

Parts Used:

-

Jeffrey from Clearwater, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers, Screw drivers

5 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The 8" burner switch would operate both the 6" and 8" burner.

First pulled the two screws holding the control with the switches. Then I unscrewed the nut holding the 6" burner switch and disconnected the wires on the switch and replaced the switch with the new one. Replaced the control unit in the range top and tested the repair.

Parts Used:

-

Jack from Carson City, NV

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Wrench (Adjustable)

5 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

burned out receptacle

Searched for parts and found PartsSelect to substantially underprice Sears for same items. removed old recept. with a screwdriver, no problem, had a little difficulty getting new wires attached as hand wouldn't fit under burner area and the wires were short. Also the recept. bracket screw hole was a little tight for the screw so I had to "stretch" it out a bit. Replacing drip pans and rings was a simple change out of the old, no tools needed for that. Overall an easy job.

Parts Used:

-

Michael from Penryn, CA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers

6 of 9 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

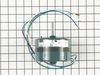

Downdraft Motor Bearings Shot

I first had to purchase the replacement motor which was quoted from a high of $236 to a low at graingers of$100. 00. The counterman at graingers removed the blower fan from the motor for me with a special long handled allen key. I then degreased and cleaned the blower fan. I had to cut off the screws on the motor and replace the 3 motor isolators and the urethane foam around the motor. I had to thread the 3 wires from the new motor through the bx cable from the old motor and reattach the fan to the motor. Anyone wanting more detailed informatioin may contact me at:mablume@optonline. Net

Parts Used:

-

MICHAEL from LAKE GROVE, NY

-

Difficulty Level:Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Screw drivers, Socket set, Wrench set

5 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The heating element socket had crumbled with age.

Changing the socket with a new one simply required removing one screw and splicing the two existing wires to the pigtails on the new socket. It took longer to unpack the replacement part than actually doing the job.

Parts Used:

-

Edward from Webster, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers, Screw drivers

4 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Burner would not get hot.....only warm. Connector was worn as well.

First, I removed the two screws holding the element in place. I removed the element from the connector. I then removed the trim ring and drip pan. I unscrewed the retaining screw holding the connector and pulled out the connector about three inches and disconnected the two wires leading to from the old connector. I removed the old connector. I then connected the two wires leading from the new connector and fasten the connector to its retainer with a screw . I reinserted the drip pan and trim ring and plugged the new element into the connector. I turned on control knob to high and tested the element., which glowed red hot. Job completed and customer very well satisfied..

Parts Used:

-

Daniel from Magalia, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

5 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Reusable Grease filter was old and worn out.

The Model number could no longer be read clearly on the stove electric grill with a down draft vent system, so all I had was the size and looks of the old grease/air filter. I was very happy to come across Parts Select by way of an amazon.com search. Their web site's design and the parts pictures with detailed descriptions made it easy to find exactly what I needed. The grease filter fit perfectly in no time. I have successfully used my cooking grill again.

Parts Used:

-

Gloria from Galveston, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

5 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The control knobs on our otherwise "healthy" Jenn-Air range were worn off and did not turn stove on correctly.

Simply pulled the old ones off and pressed on the new control knobs. It took less than 10 minutes, saved us from replazcing an otherwise nice looking range top, and made a big deposit in my "Honey do" account. I just wish they still sold the clock and timer units to fit this stove. Oh and yes, the prices were very reasonable too. Thank You Brad Harris, Illinois

Parts Used:

-

Brad from Clay City, IL

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

4 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Motor bearing failure after 34 years.

Important: Down load the helpful assembly diagram for the fan motor and study it for a few minutes. It's very straight forward. Also a good idea is to remove the bottom panel which comes off easy before starting.

My only problem was removing the existing blower/fan wheel without damaging it once I had the assembly on the work bench. It was rusted on tight and managed to remove after a few tries using penetrating oil. The wheel is in stock and I'd suggest buying a new one along with the new motor if I had to do the job again.

Bottom line; the fan motor fit perfect but did have to re-use part of the old existing electric pig tail because the motor does not come with the factory type motor terminal connectors. By using three twist on wire connectors was back in business. The down draft vent works like new.

Wife is happy...

Wade

My only problem was removing the existing blower/fan wheel without damaging it once I had the assembly on the work bench. It was rusted on tight and managed to remove after a few tries using penetrating oil. The wheel is in stock and I'd suggest buying a new one along with the new motor if I had to do the job again.

Bottom line; the fan motor fit perfect but did have to re-use part of the old existing electric pig tail because the motor does not come with the factory type motor terminal connectors. By using three twist on wire connectors was back in business. The down draft vent works like new.

Wife is happy...

Wade

Parts Used:

-

Wade from CARMINE, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers

4 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!