Parts That Fix Maytag Dryer MEDB800VQ0 Too hot

Too hot is a commonly reported symptom for the MEDB800VQ0 Maytag Dryer, and we have put together a full guide on how to fix this. This advice is based on feedback from people who own this exact appliance. We have listed the most common parts for your MEDB800VQ0 Maytag Dryer that will fix Too hot. We have included repair instructions, and helpful step-by-step video tutorials. If you are experiencing this issue, not to worry, DIYers just like you have fixed this, and shared their experience to help you!

The internal-bias thermistor (Thermistor, Dryer Thermister, Dryer Thermistor) prevents the dryer from overheating by monitoring and controlling the temperature of the inside of the dryer drum. It is located on the blower housing, next to the thermal fuse. If your thermistor is defective, drying time could be prolonged or you could get a fault code. You could also notice your dryer overheating. You can test the outlet thermistor on a multimeter, it should read 10Kohms (10,000 ohms) of resistance at room temperature. It can tolerate 10% fluctuation. If your reading indicates the part is defective, it will need to be replaced. This model is white plastic. It is sold individually.

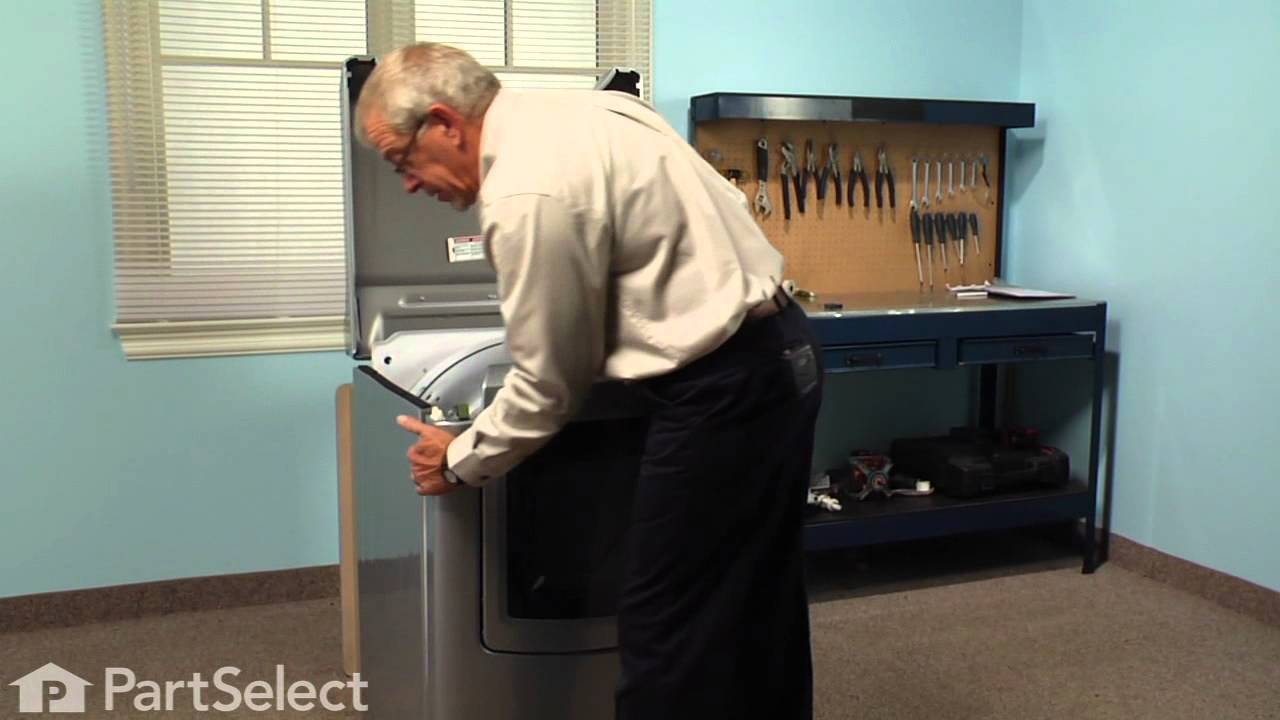

Replacing your Whirlpool Dryer Thermostat, Internal-Bias

Customer Repair Stories

Dryer turns off after 1-2 minutes

-

Dixon from Santa Fe, NM

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver

Unit would shut down in the middle of cycle and flash E1 trouble code

-

Jim from Tucson, AZ

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers, Socket set

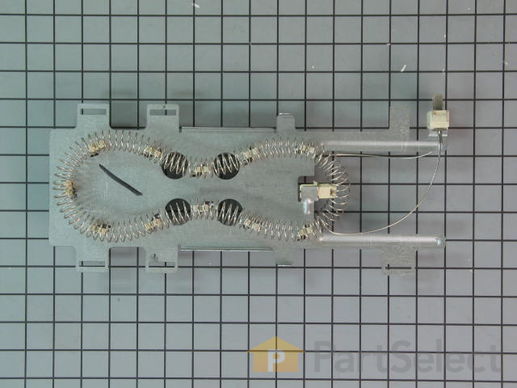

Also known as Thermal Cut-Off kit. The thermostat acts as a safety mechanism that keeps the dryer from overheating and the fuse is like a backup system - it's set to trip at a higher temperature than the thermostat. Once it trips, it has to be replaced.

Replacing your Whirlpool Dryer High Limit Thermostat and Thermal Cut-Off Kit

Customer Repair Stories

Dryer not heating

-

Stephen from Andalusia, AL

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Wrench (Adjustable)

Flashing E1 code for a bad thermistor

-

John from Cedar Rapids, IA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers

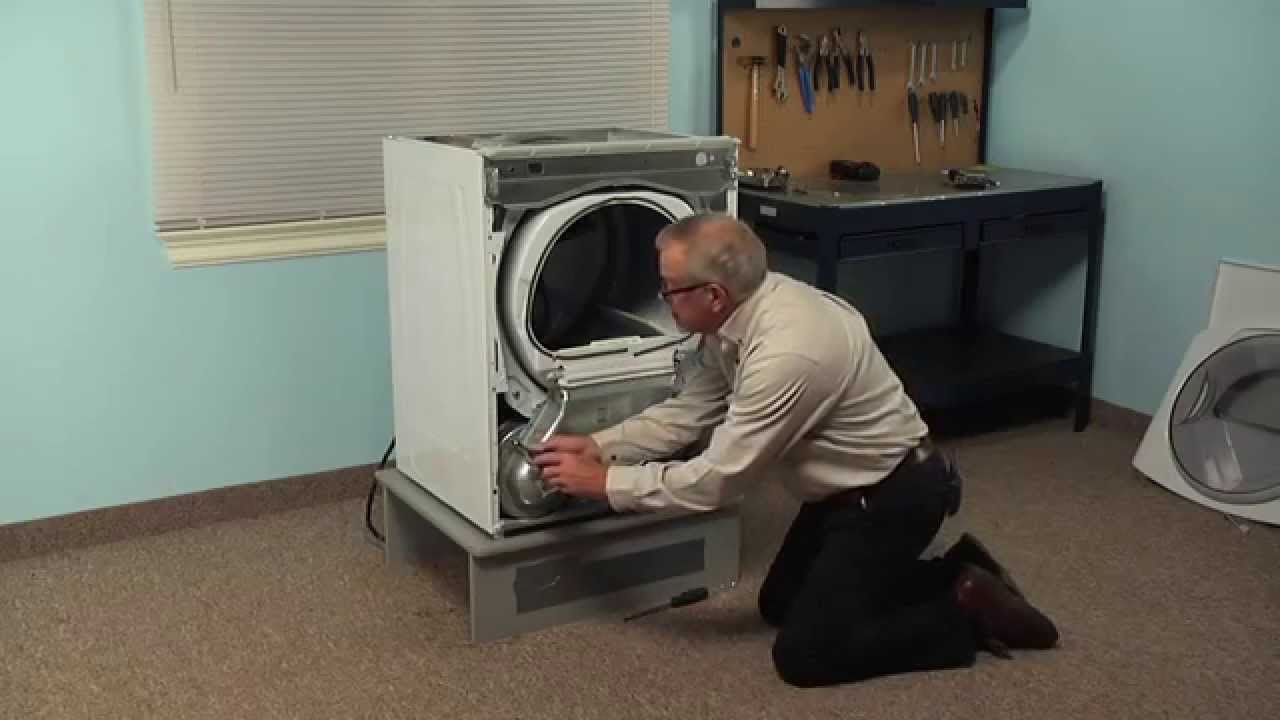

This is the moisture sensor for your dryer. It helps detect the amount of moisture in your clothes during the dryer cycle. If you notice your clothes are still wet after an automatic dryer cycle is done, you may need to replace the sensor. You will find the moisture sensor behind the lint screen. Be sure to disconnect the power source from the dryer before you begin this repair. Note: Some model's require two sensors, please order quantity needed. Sensor only, harness is not included. This part is sold individually.

Replacing your Whirlpool Dryer Moisture Sensor

Customer Repair Stories

Hard to reach the screws inside the dryer They were on the door side of the dryer and hard to reach, especially if you are a abig guy.

-

Lucy from CHADDS FORD, PA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Screw drivers

Moisture sensors need replacement

Separate filter grill from housing. Using the pliers, compress the tabs on the sensor plugs and push it thru the grill. The small blade screwdriver may come in h ... Read more andy here to pry up on sensor to assist in pulling the plug end through the grill. Replace the sensors by hooking short end into grill and pushing the long end through the grill. When replacing the housing to the dryer, the most difficult thing is getting the screwdriver onto the recessed screws. Be sure to put the tab on top of the housing under the dryer frame when rotating the assembly into place.

-

Jack from JONESBORO, AR

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers

This authentic OEM high limit thermostat is made for your dryer. It is an important dyer element, because it will automatically shut off the heating element when it overheats. Be sure to disconnect the power to your dryer before you begin this repair.

Replacing your Whirlpool Dryer Dryer Heater Element

Customer Repair Stories

Heater Element bad.

So happy with Partselect though. Super fast shipping and a perfect instructional video. Thanks!!

P.S. Wear gloves! ... Read more !!

-

Christian from JOHNSTON, IA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers

Had to replace heating element broken coil

-

Carter from NORFOLK, MA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Socket set