GHW9100LW2 Whirlpool Washer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

the pump wasnt puping out the water

firts remover the three bolts that held the front panel on, and removed that. Then removed the screw that held the pump in place. then removed the hoses from the pump. After that put hoses on new pump and srewed back in place . the put front back on.

Parts Used:

-

Evette from Mayfield, NY

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Socket set

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

I find water in the drum after a few days of non use

Removed the three screws in the back took off the top and swamped out the part. I recommend that the inlet valve is checked periodically by removing the hoses to see if there's any build up on the filter.

Parts Used:

-

Anthony from Brooklyn, NY

-

Difficulty Level:Very Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Baffle broke off

The baffles do push thru slots in the drum and by then pulling them towards you, it moves slightly locking them into place. There are screws supplied and they could be installed to aid in the baffles not coming off as ofter but this cannot by done by the average person for you would need special tools and allot of fixet smarts and patience. My washer can be set at a higher spinout speed and this does save on drying costs but the trade off is the baffles break off way too often. There are metal tabs in the drum that are raised up and snap behind tabs on the underside of the baffles as you slid them towards you install them. If you rebend these tabs up with a longnose pliers twice as high as they are, they will have more holding force, keeping the baffles from coming off as often. In my opinion, the baffles should have been designed to slide backwards to lock them in place, not foward. If you look at how they are shaped, they natually have pressure pushing them towards the back of the drum in the spin cycle which just contributes to the problem of them coming off in the first place.

Parts Used:

-

Robert from Ellison Bay, WI

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Water would accumulate in the washer drum over several days of non use

Repair was very simple. First watch the video that is available on this website. The installation went exactly like the video described. I pulled the washer away from the wall a few inches. Removed the three screws that hold the top on. Removed the top. Shut off the water and removed the water lines. Removed the single screw that holds the inlet valve in place (T20 torx).Removed the inlet valve, removed the hose from the valve. Reversed the operation to re-install. About a 20 minute job, tops. Tested the washer when finished and it worked great. It has been a couple of weeks now and no water has accumulated in the drum.

Parts Used:

-

Ronald from RUSSIAVILLE, IN

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Pliers

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

PUMP HOUSING LEAKS

REMOVE AND REPLACE. FLEXIBLE RUBBER CONNECTOR WAS NOT A EXACT REPLACEMENT, THE ORIGANIL HAD A BACK STOP VALVE, NOT SURE OF THE EFFICATE ON MACHINE.

Parts Used:

-

JOHN from OMAHA, NE

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

4 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Torn bellow lip

Replace bellow with help from Youtube video.

Parts Used:

-

Christopher from MORGAN HILL, CA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Socket set

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

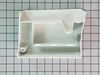

Bent slide on pedestal

Note that the problem was with the pedestal, not the washing machine. In the process of attaching the two units together, the drawer in the pedestal is removed. When I tipped the assembly up, the slide slid out and locked horns with an object, bending the slide. The slide is an easy replacement. Just one screw holds it in place. A slot in the slide mates with a tab to hold the back side of the slide in place.

Parts Used:

-

Donald from Greenfield, WI

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver

4 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Error codes SUD and Fo2

Remove three screws on bottom panel lift up and remove panel.The water pump in right in front. One screw holds it in place and the input and output hoses are on the back side.The hose clamps are a little hard to take off I found that before taking the one screw off the pump remove these two lines.Putting the pump back in secure the pump with the one screw. The output line is easy the intake line can be a bit of a more work to get it on because the rubber is so thin.Getting this hose and clamp was tough. Most of all use a wet vac to remove water in washer and vac out the line to drain doing this will be water free during replacing water pump.Run a cycle to make sure the lins do not leak. The other is the people that has posted this replacement are very good

Parts Used:

-

Gregory from LEXINGTON, SC

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Broken parts

Removed old parts and installed the new parts.

Parts Used:

-

Gregory from CITRA, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer wouldn't drain

-

Jeff from Barrington, RI

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

wont pump the water out

Had the old pump out - 1 screw and two hose clamp to unhook and an electrical wire to pull out - couldnt been any easier - when new one came took 5 mins to install - did a load to make sure pump worked before put it all back together

Parts Used:

-

Paul from Corning, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers, Screw drivers

3 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

broken handle

Just removed two screws with a phillips screwdriver and screwed the new handle on. Super simple

Parts Used:

-

Judith from Thousand Oaks, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The door handle had cracked and broken off

First I removed the two screws that held the old handle and then replaced the new handle with the same screws.

Parts Used:

-

Dustin from Mount Dora, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Bellow pierced

1. Remove bottom panel (3 screws below). 2. Remove top panel (3 screws back). 3. Remove detergent dispenser (remove T screw in front.) 4. Carefully remove control panel is plastic so be careful not to break it. 5. Pull broken bellow from front and spring loaded clamp will come lose. 6. Push away bellow. 7. Remove cables from door lock. 8. Remove front panel screws (4 - 2 on top and 2 in bottom). 9. Unscrew bellow's clamp with flat screw driver or not driver. 10. Remove worn bellow. 11. Bellow has notch on top (Use as reference to replace. 11. Clean all surfaces. 12. Install new bellow to drum. 13. Screw clamp over of bellow not too tight. Don't want to break the seat. 14. Replace all in the reverse order and for the front of the bellow refer to my previous article (story) on front latch replacement.

Parts Used:

-

Alexander from Miami, FL

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers, Socket set

4 of 8 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Door Handle broke off.

This was truely easy. All I needed was a flat head screw driver and it was done within five minutes.

Parts Used:

-

Maxine from Wilmington, NC

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!