CYG1005AWW Magic Chef Dryer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Dryer not heating

Terminal Block was cracked and dryer was not receiving enough voltage, causing the heating element not to heat. Here were the steps I took to fix the problem:

1. Turn off breaker to dryer from 240v outlet

2. Unplug dryer from 240v wall outlet.

3. On outside, rear of dryer, remove cover plate and the clamp that the power cord goes through with nut driver or phillips screwdriver and take picture or write down how the power cord wires go to the terminal block.

4. Use nut driver or phillips screwdriver to remove the power cord wires from terminal block and ground wire from dryer body.

5. On top front of dryer, use large slotted screwdriver or some other tool to push in on the two clips in order to lift the cover up on dryer.

6. Take picture or write down how wires are attached to terminal block.

7. Remove wires from terminal block with nut driver or phillips screwdriver.

8. Use nut driver to remove terminal block from washer and install the new terminal block.

9. Reinstall wires to new terminal block.

10. Close dryer cover.

11. Reinstall clamp onto power cord wires and reinstall wires to new terminal block and ground wire to washer body then put cover plate back on.

12. Plug in dryer then turn on breaker.

13. Start dryer to see if it heats now.

1. Turn off breaker to dryer from 240v outlet

2. Unplug dryer from 240v wall outlet.

3. On outside, rear of dryer, remove cover plate and the clamp that the power cord goes through with nut driver or phillips screwdriver and take picture or write down how the power cord wires go to the terminal block.

4. Use nut driver or phillips screwdriver to remove the power cord wires from terminal block and ground wire from dryer body.

5. On top front of dryer, use large slotted screwdriver or some other tool to push in on the two clips in order to lift the cover up on dryer.

6. Take picture or write down how wires are attached to terminal block.

7. Remove wires from terminal block with nut driver or phillips screwdriver.

8. Use nut driver to remove terminal block from washer and install the new terminal block.

9. Reinstall wires to new terminal block.

10. Close dryer cover.

11. Reinstall clamp onto power cord wires and reinstall wires to new terminal block and ground wire to washer body then put cover plate back on.

12. Plug in dryer then turn on breaker.

13. Start dryer to see if it heats now.

Parts Used:

-

Henry from LA FOLLETTE, TN

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

heard the sound of loose change in the dryer

removed the front panel and the drum panel cover.replaced the guides and the felt pads and re-assembled.

Parts Used:

-

Robert from Averill Park, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

broken lint screen

-

Marlo from DeKalb, IL

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Belt Was Broken

Unable to find a repair manual or accurate diagram, I forged ahead and removed the top and front panels of the dryer. It took two tries to figure out how to thread the belt (nine of my ten thumbs kept getting in the way!), but after a coffee break, the job came together, and I've taken the clothesline down!

Parts Used:

-

Richard from Kealakekua,, AL

-

Difficulty Level:Really Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Very loud intermittent squealing noise while dryer was running

Unlike the other stories I read (and the video posted on the site), my unit had a lower maintenance panel on the front face which required quite a different disassembly. Once I took off the lower panel, there were screws at the bottom of the top panel. Once removed, the top front panel came out and exposed the necessary interior components. In order to get the drum out, I took out the screws holding the front of the top on and wiggled the drum out. From there I removed the belt and offending idler lever, put in the new ones and hooked the spring back up. Reverse procedure to assemble and the problem is completely gone. I even found and removed an unexpected hair band from the front skid plate. Pretty doable if you're willing to spend the time.

Parts Used:

-

Jason from Buffalo Grove, IL

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set, Wrench set

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Button to start dryer

Per instructions I printed off online: took off door, then the front panel. Pulled out the old switch/button, connected the new switch/button, made sure the new button was working; put the panel back on then the door and DONE!

Parts Used:

-

Loretta E. from Miamisburg, OH

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

4 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

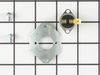

Gas flame would not relight after it reached its first heat cycle.

I removed the two spade connectors and then removed the two 1/4" hex screws. I then simply removed the defective unit and replaced it with the new on and re-installed the two screws and wires.

This was not the problem though.

I turned out to be the solenoids on the gas valve.

This was not the problem though.

I turned out to be the solenoids on the gas valve.

Parts Used:

-

David from Humble, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver, Screw drivers

4 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer stopped working & lint filter torn to shreds

Remove screws to top of appliance lid and control panel paying close attention to location and type of screws. Lift back of top panel and lift off front top lid until it snaps up. Slide top panel to side and remove upper front panel screws from the inside of dryer one on left and one on right. Be careful to not let front door fall outward. Slide door panel up off of hooks at base of panel. Remove duct assembly by removing three screws located on the inside of the dryer at the front. Slide out and remove air duct assembly.

Removing the High Limit Thermal Fuse was straight forward. Didn't really understand the online instructions but performed a continuity test across terminals and there was no continuity, so I replaced.

Repare took 1-2 hours, next time will probably cut in half now that I know where to remove screws to access motors & fuses and dryer assemblies at base of dryer.

Removing the High Limit Thermal Fuse was straight forward. Didn't really understand the online instructions but performed a continuity test across terminals and there was no continuity, so I replaced.

Repare took 1-2 hours, next time will probably cut in half now that I know where to remove screws to access motors & fuses and dryer assemblies at base of dryer.

Parts Used:

-

LEMONT from WINDOW ROCK, AL

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Wrench (Adjustable)

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The dryer made a random grinding/rubbing noise during operation.

After removing the lower access panel, I observed the drum and belt and saw it turning freely. The support rollers in the back turned freely and were in good condition as well. At odd intervals the unit made a humming or grinding noise, and i decided to check the blower wheel (the other rotating part in the system). I found that the central hub of the wheel (which is made of a nylon like plastic) had sheared off from the wheel itself. I ordered a new part and started to remove the old wheel. **NOTE** many of the stories I read described how this part would have a reverse thread, it did not and that cost me an extra 30 minutes to figure out (the new part had arrows showing the correct direction to put on and remove - the original didn't). Once everything was cleaned and reassembled, I started the dryer again, but got no heat. I had previously replaced the heating element, so I thought my wiring was wrong. That wasn't the problem, but a hint from this site about checking the incoming wiring was the solution, my ground wire had come off the terminal in the back of the dryer and I wasn't getting the volatge across the element that it required. With the ground wire back in place, everything worked fine.

Parts Used:

-

Timothy from Hardeeville, SC

-

Difficulty Level:Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Wrench (Adjustable)

4 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Air duct assembly broken.

I used a large flat head screwdriver to lift top up, then located 2 screws in the top right and left hand side to remove front. Remove the three Phillip Head Screws that holds the assy in place slide out. Mine had 2 metal pieces with wires. I simply unplugged and took metal pieces and installed in the new assy. Remove excess lint put front back on lowered lid and done! 15-20 minutes

Parts Used:

-

Thomas from Summerville, SC

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Worn Felt Seal

remove bottom two screws on lower front panel, remove panel. remove two screws on lower portion of door panel, pull bottom panel towards yourself to release pins at the top. Disconnect wiring for light and door switch (make sure to note what wires go where. Complete removal of front door panel. Remove 4 screws holding cylinder frame in place, lift to remove. remove remnants of old felt seal, use rotary tool to remove excess glue, etc. apply glue (used rubberized gorilla super glue), apply felt seal - allow glue to set up. reinstall in reverse direction from removal. Be sure to use glue as there are no clips or other retaining pieces for the new felt and it will not hold in place. overall pretty easy.

Parts Used:

-

robert from hillsborough, NC

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

3 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Vent filter was broken, and lots of lint was passing through to vent line

Removed the two nuts at the bottom of the dryer front to be able to move the front piece. Removed three screws holding the vent assembly in place. Removed vent assembly, replaced with new part and replaced screws and nuts.

Parts Used:

-

Amy from Petaluma, CA

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers, Wrench (Adjustable)

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

noise in dryer

took frount off ,then filter, pulled drum out, then blower plate & spun impeller off. went back together easy ,except belt . that gave me a little problem but finally got it thanks

Parts Used:

-

JOHN from MODENA, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Socket set, Wrench (Adjustable)

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

will not blow air

I first unpluged the dryer. Then I

Removed two screws and removed bottom cover, Then removed the door assembly.Here I had to unplug the light and door switches. I then removed the four screws that holds the tub mount in place, Then I removed the eight screws that hold the blower cover in place, then removed the blower. replaced blower and reassembled in reverse. I started the dryer and it worked fine.

Removed two screws and removed bottom cover, Then removed the door assembly.Here I had to unplug the light and door switches. I then removed the four screws that holds the tub mount in place, Then I removed the eight screws that hold the blower cover in place, then removed the blower. replaced blower and reassembled in reverse. I started the dryer and it worked fine.

Parts Used:

-

Robert from Ada, OK

-

Difficulty Level:Really Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers

3 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer sounded like it was going down manhiem road (pot holes).

I removed the access panel on the lower front. Then I removed the front door panel (noting where the wires went; 1 for red, 2 for black, 3 for grey). Then I removed the 2 screws holding the top down and lifted it up. Then I reached underneath the drum and took the belt off the tensioner. Then I removed the front drum panel with the lint filter, guides, and front felt seal. Then I took out the drum. Then I replaced the roller and post (with bracket). The old post was worn, so it was a good thing I got the new post (thanks to someone else's reccomendation). Then I put it all back together. It was surprizingly easy. I just wish these parts weren't so dad gum expensive. I paid $20 for one roller and post. I wish I could have also replaced the felt seals ($17 each), the other roller (another $8) and the sliders and felt pads ($20 per side). And a new belt. By then, you might as well buy a new dryer!

Parts Used:

-

Bradley from Crest Hill, IL

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!