ALG331RAC Amana Dryer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Would not lite

-

RICHARD from LINDSTROM, MN

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Socket set

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The female catch in door was bro9ken

-

JOSEPH from ANSONIA, CT

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

2 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

lint filter

-

shirley from sherman, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

2 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Idler Pulley Bearing froze

First of all I would not have done this if it wasn't for

your website. Using the schematics to figure out

the right parts was easy. It was also helpful in the

actual repair process. I have added your website

to my favorites in my browser. The parts arrived in 3 days and I live in Reno. Great Website.

M.B.

your website. Using the schematics to figure out

the right parts was easy. It was also helpful in the

actual repair process. I have added your website

to my favorites in my browser. The parts arrived in 3 days and I live in Reno. Great Website.

M.B.

Parts Used:

-

Maure from Sparks, NV

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Wrench set

2 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

replace door closer

Removed power and front panel, removed broken latch, pushed in new latch and replaced the front panel and power. Done

Parts Used:

-

Erwin from Somersworth, NH

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers, Socket set, Wrench set

2 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

dryer door would not close

discovered it was a broken latch. Ordered the latch, only took 2 days to arrive and all I had to do was remove the broken latch and snap in the new one. I saved myself a service call. I'm very happy!!!!!!

Parts Used:

-

Priscilla from Portland, ME

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

2 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

broken door clip

After watching the great install video, I followed his lead and within 20 min had my dryer door fixed. This dryer was bought in 1986 and I really thought I was looking at buying a new dryer. How wonderful that I could fix it for less than $11. Easy to find web site, easy to find part, great instructions and fast delivery!

Parts Used:

-

Lynette from Rock Island, IL

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

2 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

top of the lint filter broke off, tearing our clothes.

Ordered the part, you made it so easy. Received it in two days, very fast, by regular mail. Perfect fit. Pulled out the old broken one and put in the new one!

Parts Used:

-

Betty from Melissa, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

2 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Screeching dryer followed by later clunking when roller went

I pretty much followed a lot of the earlier postings on partselect.com that provided encouragement to pursue replacing this part on my 17 year old dryer (sorry, money is tight these days and I prefer repair to $800 replacement).

I'd like to add that I borrowed a pair of snap-ring pliers from work which made removal and later securing of roller onto shaft much easier and probably avoided a lot of knuckle bruising and cursing.

I erred though in a couple of places during the replacement. Disassembly took about 20 minutes. However, when I re-assembled I had mistakenly already put the roller onto the shaft before trying to put the drum back in. That isn't possible so I had to remove (an initial groan but only a few extra minutes in the end) the roller from the shaft, then reposition the drum and then the roller back on the shaft.

I also decided to replace the belt while I was in there and I should have taken a picture or made a drawing of the belt route before I took it off since I was later left pondering how the heck to snake the belt onto the shaft and also the tensioner. A quick trip to the internet though showed me a similar route and reminded me how to route it.

I'd also like to add to be cognizant of the wires on the door and front panel when disassembling.

Anyone with any sense of mechanical ability and a little common sense ought to be able to do this repiar.

Thanks Part Select!

I'd like to add that I borrowed a pair of snap-ring pliers from work which made removal and later securing of roller onto shaft much easier and probably avoided a lot of knuckle bruising and cursing.

I erred though in a couple of places during the replacement. Disassembly took about 20 minutes. However, when I re-assembled I had mistakenly already put the roller onto the shaft before trying to put the drum back in. That isn't possible so I had to remove (an initial groan but only a few extra minutes in the end) the roller from the shaft, then reposition the drum and then the roller back on the shaft.

I also decided to replace the belt while I was in there and I should have taken a picture or made a drawing of the belt route before I took it off since I was later left pondering how the heck to snake the belt onto the shaft and also the tensioner. A quick trip to the internet though showed me a similar route and reminded me how to route it.

I'd also like to add to be cognizant of the wires on the door and front panel when disassembling.

Anyone with any sense of mechanical ability and a little common sense ought to be able to do this repiar.

Thanks Part Select!

Parts Used:

-

Joseph from Upper Montclair, NJ

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers, Socket set

2 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Loud Grinding type noise - Broken Blower Wheel

Very simple repair. Remove front panel, door, drum etc. Try to keep everything seperated, screws etc. I put lockjaws on the back to get the nut off the front. Make sure to check the housing for "melted on" blower wheel residue. Easy enough to remove. I checked with my local parts dealer he wanted twice the price and needed to order it (at least a days wait). PartSelect sent the exact same part in a day and a half. Put everything back the same way I removed. Hardest part is the drum and belt. While you have everything apart don't forget to clean the thermastats etc. PartsSelect was quicker and cheaper.

Parts Used:

-

Ron from Portage, MI

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Socket set, Wrench (Adjustable)

2 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer would start loud humming noise 20-30min into cycle-rear bearing going bad

Unplug Dryer. Remove 2 5/16in hex screws fm lower panel,3 51/6in hex screws to vent duct. Remove 2 1/4in hex screws to thermostat. Remove 7 1/4in hex screws to blower cover and 2 5/16in hex screws holding base footings.Use adj. wrench to hold rear nut on motor shaft, use7/8in socket to remove fan frm motor shaft. Remove 3 5/16in hex screws holding fan housing to motor mount. Lift-up on spring tensioned belt pulley to remove belt. Pull motor & mount out [wires are layed toward front allowing removal]. Use 6in flat tip screwdriver to unsnap both front/rear motor clamps.Pinch plastic end clamps and remove motor electrical connector.Motor installation is reverse. For belt removal,remove 2 5/16in hex screws to door panel [unhook 2 wires to upper RT rear to door switch].Remove 4 5/16in hex screws to front bulkhead panel.Allow drum to sag IN PLACE [removal not required to replace belt],note belt location and slide old belt off and new one on

Replace Bulheald and door panel [re-attach door switch wires].Complete install by lifting belt pulley and feeding new belt into place. Hand rotate drum to ensure proper belt allignment and tracking. Replace lower panel. Vacuum interior as necessary. Parts delivered in 3days and fit perfectly.

Replace Bulheald and door panel [re-attach door switch wires].Complete install by lifting belt pulley and feeding new belt into place. Hand rotate drum to ensure proper belt allignment and tracking. Replace lower panel. Vacuum interior as necessary. Parts delivered in 3days and fit perfectly.

Parts Used:

-

Gregory from Virginia Beach, VA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers, Socket set, Wrench (Adjustable)

3 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer drum wouldn't turn and motor would shut off

First I was told by the maytag repair man that the motor was shot and it would be 467 dollars to repair. Since I didn't have that kind of money I decided to take it apart to see if I could replace the motor myself. Once I had it apart I saw the part that held the motor in place was broken off and the motor was out of place causing it too shut itself off. Once I figured it all out it took about 2 minutes to replace the less than 6 dollar part! Thanks partSelect!!!

Parts Used:

-

Cynthia M from Westfield, MA

-

Difficulty Level:Easy

-

Total Repair Time:More than 2 hours

-

Tools:Screw drivers

2 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Air duct was broken,taking too long to dry

removed the bottom panel. then the door. unscrewed the 4 screws, removed duct and replaced. parts came fast and fit just right! no issues at all! I recomend Parts select as an appliance vendor for parts.

Parts Used:

-

GILBERT from SAN JOSE, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers, Socket set

2 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

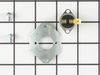

Drying time exceeded 1 to 2 hours and lint was damp on lint screen

Removed two screws on lower front dryer panel with 5/16" socket and wrench. Removed three screws and plastic filter dryer screen vent with 1/4" socket allowing easy access to upper limit thermostat switch located on side of igniter flame assembly tunnel. Removed two screws attaching limit switch and disconnected two wires. Replaced with new limit switch and reconnected wires. Reassembled dryer. Works fine. Drying time for regular items such as towels is now less than 1 hour.

Parts Used:

-

JAMES from VALENCIA, CA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers, Socket set

3 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Loud Squealing Sound When Dryer Is Running>

First unplug the dryer,then remove the front bottom panel. With your 5/16 nut driver reach to the rear of the vent tube under the dryer and remove the lone screw that holds the tube in place. Lean the dryer forward and remove the tube from the rear of the dryer,this will allow you to see and reach the idler wheel from the front. Release the belt,feel for the clip that holds the wheel in place on the opposite side of the front,with your thumb nail or something else if preferred pry out on one side of the clip until it pops off. Slide the wheel off being careful not to lose the washer,slide the new wheel on and replace the clip. Put the belt back on replace the tube,which is actually the toughest part because you have to find the hole for the lone screw as you can't see it,but with a little patience it is easily enough done. Put the vent hose back on replace the front panel and plug it in and go!!it took me 30 min. Alittle tough to feel for some of the parts,but really much easier than you would think.

Parts Used:

-

Michael from Milton, FL

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver

3 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!