Models

>

WED6200SW1

WED6200SW1 Whirlpool Dryer - Overview

Sections of the WED6200SW1

[Viewing 3 of 3]Manuals & Care Guides for WED6200SW1

Click to downloadInstall

Installation Instructions

(4.2MB)

Install

Installation Instructions

(4.46MB)

Manual

Owner's Manuals

(1.9MB)

Manual

Owner's Manuals

(3.46MB)

Manual

Owner's Manuals

(1.73MB)

Manual

Owner's Manuals

(8.53MB)

Specs

Product Specifications Sheet

(0.28MB)

Keep searches simple, eg. "belt" or "pump".

Dryer Thermal Fuse

PartSelect #: PS11741460

Manufacturer #: WP3392519

The Dryer Thermal Fuse (Thermal Cutoff, Temperature Fuse) is a 2 by ½ inch, white, plastic safety mechanism that stops the flow of electricity to the motor circuit when a dryer overheats. If the fuse ...

$19.63

In Stock

Heating Element - 240V 5400W

PartSelect #: PS334313

Manufacturer #: 279838

The heating element (Flat Can Heating Element 5400W, Heating Element, Whirlpool Dryer Heating Element, Dryer Heating Element) provides heat to the dryer. It is metal and measures 10.5 inches long, 7.5...

$64.90

In Stock

Thermal Cut-Off Kit

PartSelect #: PS334299

Manufacturer #: 279816

The thermal cut-off (Dryer Thermal Cut-Off Fuse Kit, Dryer Thermal Cut-Off Kit) prevents the dryer from overheating when the dryer high limit thermostat fails in a closed circuit condition. This part ...

$36.58

In Stock

Maintenance Kit

PartSelect #: PS373087

Manufacturer #: 4392065

The drum support roller kit (Dryer Repair Kit) allows the dryer to tumble properly by supporting the drum cylinder. The idler pulley provides the tension required for a multi-ribbed belt. The belt att...

$37.48

In Stock

Door Catch

PartSelect #: PS11748369

Manufacturer #: WPW10111905

This replacement door catch is for your dryer door. If the catch is broken and the door will not stay shut, the dryer may not turn on. Use a putty knife to pop out the existing door catch by the locki...

$7.37

In Stock

Dryer Drum Support Roller

PartSelect #: PS11752609

Manufacturer #: WPW10314173

This drum support roller is sold individually. Most dryers require two. The tri-rings are included. This is a drum support roller for a dryer. It is a genuine replacement part. The part includes the d...

$22.69

In Stock

Thermostat, Internal-Bias

PartSelect #: PS11746740

Manufacturer #: WP8577274

The internal-bias thermistor (Thermistor, Dryer Thermister, Dryer Thermistor) prevents the dryer from overheating by monitoring and controlling the temperature of the inside of the dryer drum. It is l...

$47.74

In Stock

Roller Support Tri-Ring

PartSelect #: PS11755850

Manufacturer #: WPW10512946

If you notice that your dryer is noisy or will not tumble, you may need to replace the tri ring. This part is triangular, and is less than an inch in size. Tri rings can be found both on the idler pul...

$13.42

In Stock

Leveling Foot

PartSelect #: PS1609293

Manufacturer #: 49621

If your washer shakes or vibrates loudly when it reaches its max speed, check that the leveling legs are even. To ensure that the washer is firmly on the ground using all four legs, adjust the legs so...

$11.40

In Stock

Heating Element Connection Wire Kit

PartSelect #: PS334206

Manufacturer #: 279457

This kit is used for electric clothes dryers, and it comes with a yellow wire nut.

$11.06

In Stock

Light Bulb - 10W

PartSelect #: PS11739347

Manufacturer #: WP22002263

This ten watt appliance light bulb is two inches tall. It is used with both washers and dryers.

$16.32

In Stock

Screw, 8/18 x 3/8

PartSelect #: PS11746840

Manufacturer #: WP90767

This screw is sold individually.

$5.42

In Stock

Questions And Answers for WED6200SW1

We're sorry, but our Q&A experts are temporarily unavailable.

Please check back later if you still haven't found the answer you need.

Sort by:

- < Prev

- 1

- 2

- Next >

Search filter:

Clear Filter

Your search term must have 3 or more characters.

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Sorry, we couldn't find any existing answers that matched.Try using some different or simpler keywords, or submit your new question by using the "Ask a Question" button above!

John

July 5, 2021

Makes a squealing noise from time to time

For model number WED6200SW1

Hello John, Thank you for the question. Normally this is an indication the Roller Wheels, Idler or belt will need to be replaced. We suggest ordering the Maintenance Kit. The kit includes the drum belt, drum support rollers, one idler pulley, four tri-rings, and one clip. We hope this helps!

5 people found this helpful.

Was this helpful?

Thank you for voting!

Related Parts:

Donald

January 6, 2020

I turn the power on my dryer and it’s not working it keeps lighting up sensing what does that mean

For model number WED6200SW1

Hi Donald, Thank you for your inquiry. Although usually your control board can be the culprit for something like that. You should test the Thermal Fuse in your appliance. Sometimes that can be the cause of your machine stuck in the sensing mode. To test your fuse, you will need a multi-meter. First unplug your appliance and remove the fuse. Set the multi-meter on the lowest setting. The calibrate the needle until it lands on zero. Then you take the two probes and place them on the prongs of your fuse. If the needle stays on zero, then your part will need to be replaced. I hope this helps!

4 people found this helpful.

Was this helpful?

Thank you for voting!

John

February 13, 2020

To help someone else: Issue was display would light up when powered on but would not run when pressed start and only make click sound without error code. Did diagnostic (3 sec pressing, 3x off/on, any button but power, start or pause) and received f25. Checked ohm on thermal fuse wp3392519, it was 1.25m ohms but should be close to 0. Was told by sears that f25 was thermistor wp8577274. Replaced both and it works.

For model number WED6200SW1

Hello John, thank you for sharing your experience. We are glad to hear your repair went well.

2 people found this helpful.

Was this helpful?

Thank you for voting!

Danny

May 8, 2023

my dryer is squeaking when drying sometimes not all the time

For model number WED6200SW1

Hi Danny, thank you for the question. We have found that if the drive belt becomes loose, it wraps around the outside of the dryer drum and can cause squeaking. We would recommend checking the drive belt, part number PS11746376, to fix the issue. We hope this helps, good luck with this repair!

1 person found this helpful.

Was this helpful?

Thank you for voting!

Related Parts:

Brian

November 5, 2021

Ordered thermal cutoff kit for dryer , part # 279816 , but the high limit thermostat in kit is not correct. High limit for my dryer , part # 8577891 , has more wires. Is there a cutoff kit for my dryer? If not , how can i get only the thermal cutoff without buying a whole kit? Thanks

For model number WED6200SW1

Hi Brian,

Thank you for your question. There is a thermal cut-off kit for your dryer. The part number listed under your model number for the thermal cut-off kit is PS334299. If you would like to place an order for it, you may order it either online or by calling our customer service line and anyone will be happy to assist you. We hope this helps! If you have any questions, please let us know.

Was this helpful?

Thank you for voting!

Related Parts:

- < Prev

- 1

- 2

- Next >

Common Symptoms of the WED6200SW1

[Viewing 11 of 11]Noisy

Fixed by

these parts

these parts

Show All

Door won’t close

Fixed by

these parts

these parts

Show All

Too hot

Fixed by

these parts

these parts

Show All

Not Heating

Fixed by

these parts

these parts

Show All

Drum Not Spinning

Fixed by

these parts

these parts

Show All

Won’t Start

Fixed by

these parts

these parts

Show All

Touchpad does not respond

Fixed by

these parts

these parts

Show All

Heat stays on after drum has stopped

Fixed by

these parts

these parts

Show All

Marks left on clothes

Fixed by

these parts

these parts

Show All

Will Not Start

Fixed by

these parts

these parts

Show All

Door Pops Open

Fixed by

these parts

these parts

Show All

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

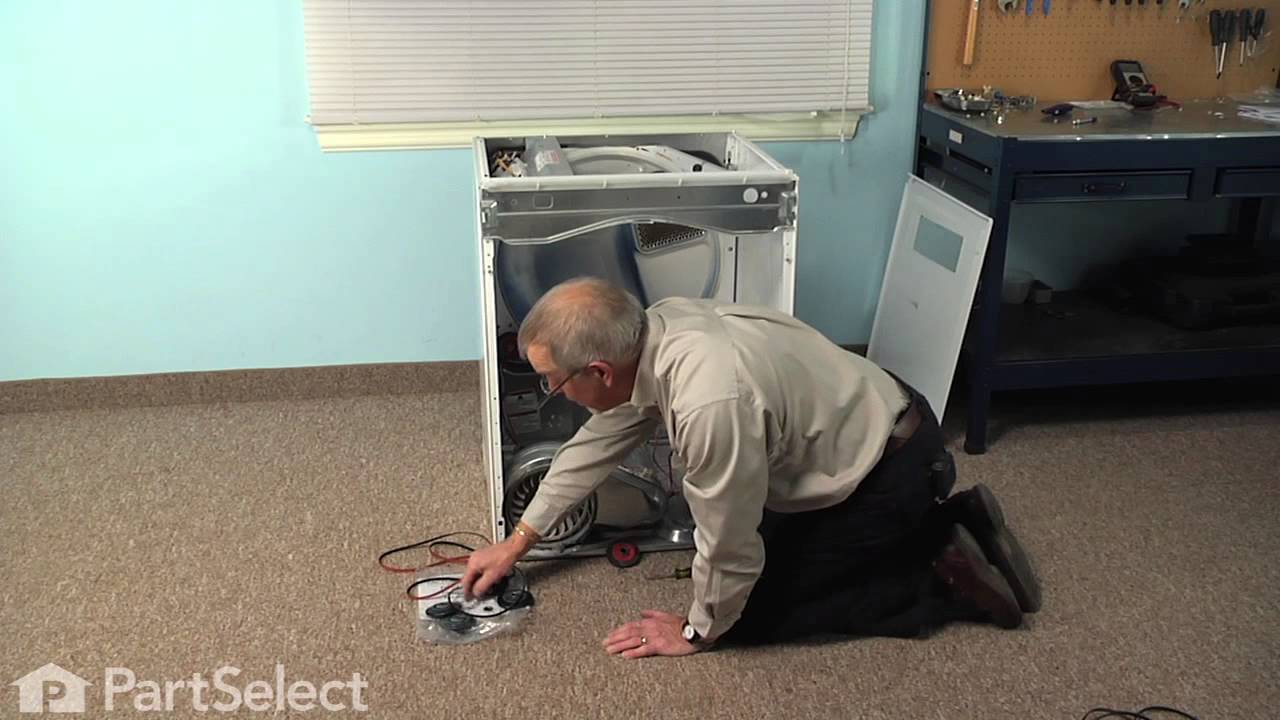

Dryer was working, but no heat.

First I unplugged the dryer, then removed the back panel, this exposed most all of the wiring and I could see the heater coils.

Not knowing what the problem was I started looking at the coils and could not see any broken parts.

So then checked the thermal fuse for continuity I removed the two wires from it with a small pair of ... Read more needle nose pliers, it was held in place by two screws, once they were removed the fuse came out easily, I checked continuity with a volt meter placing the meter on X1 Ohms and could not get a reading.

I replaced with a new one and put it all back together the way I took it apart.

Then I plugged it in and it worked first time, I now have warm dry clothes.

Not knowing what the problem was I started looking at the coils and could not see any broken parts.

So then checked the thermal fuse for continuity I removed the two wires from it with a small pair of ... Read more needle nose pliers, it was held in place by two screws, once they were removed the fuse came out easily, I checked continuity with a volt meter placing the meter on X1 Ohms and could not get a reading.

I replaced with a new one and put it all back together the way I took it apart.

Then I plugged it in and it worked first time, I now have warm dry clothes.

Read less

Parts Used:

-

ANTHONY from CHESHIRE, CT

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Pliers, Screw drivers

2965 of 3338 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer motor runs, but no heat

To reach the heating element you only need to open the back cover of the dryer (about 8 nut-head screws). Remember to disconnect the power.

To remove the heating element there are two small nut-head screws. Remove the two electric wires. Then you can pull the heating element away.

You can check the heating element wi ... Read more th an ohm-meter or visually inspect it to see if the heating element spiral wire is broken.

Don't hurry to dispose the old element. My model includes a small electric safety part. You'll need to transfer it to the new heating element (that comes without it)..

Good luck.

To remove the heating element there are two small nut-head screws. Remove the two electric wires. Then you can pull the heating element away.

You can check the heating element wi ... Read more th an ohm-meter or visually inspect it to see if the heating element spiral wire is broken.

Don't hurry to dispose the old element. My model includes a small electric safety part. You'll need to transfer it to the new heating element (that comes without it)..

Good luck.

Read less

Parts Used:

-

Gadi from Irvine, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver

2256 of 2437 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

No Heat

First tried heating element and thermal fuse with no luck. Ordered thermal cutoff and fixed problem. Had I used an ohm meter first I would have determined problem before having ordered heating element and fuse, as both had resistance. I wast just lazy and ordered the took the most common failed components first before taking dryer back

... Read more

off.

Read less

Parts Used:

-

Vernon from Niceville, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver

886 of 948 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!