Parts That Fix Admiral Washer ATW4475XQ0 Spins slowly

Spins slowly is a commonly reported symptom for the ATW4475XQ0 Admiral Washer, and we have put together a full guide on how to fix this. This advice is based on feedback from people who own this exact appliance. We have listed the most common parts for your ATW4475XQ0 Admiral Washer that will fix Spins slowly. We have included repair instructions, and helpful step-by-step video tutorials. If you are experiencing this issue, not to worry, DIYers just like you have fixed this, and shared their experience to help you!

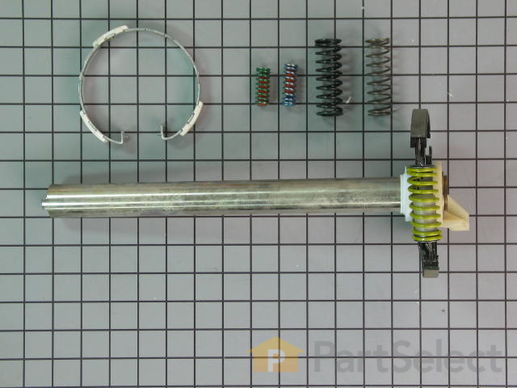

A clutch assembly (Clutch, Washer Clutch) is found in your washing machine and is responsible for spinning the basket during the spin cycle. The clutch lining can wear over time. If the clutch lining is worn out, the clutch assembly will not rotate properly to release the brake. If you notice a burning smell, or the machine shaking and moving more than normal, this could indicate there is an issue with your clutch. If the washer spins when the washer basket is empty but not when it’s full, or if the assembly begins to turn blue, you may need to replace the clutch assembly. This assembly includes a brake cam driver, blue springs for large capacity washers, a black spring for compact washers, and the installation instructions. It’s constructed of plastic and metal, and comes in beige/silver.

Replacing your Whirlpool Washer Clutch Assembly

Customer Repair Stories

Clothes washer would not spin with more than a couple socks in it. It would barely spin when empty.

Summary:

Get the washer on its back - unplugged!

remove wire(s) Harness from motor

remove water pump

unbolt 3 bolts holding the gearbox

slide gearbox and motor out as one piece ( a bit heavy)

remove and replace clutch assembly (pay attention to how things are removed)

Done! put it all back together... hope that helps. It worked perfect for me.. and m

-

Shawn from Longmont, CO

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers, Socket set

spin cycle did not engage

-

Andrew from SLC, UT

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Socket set

This direct drive motor coupling (Direct Drive Washer Motor Coupling, Motor Coupling, Washer Motor Coupling, Coupling Kit) provides a cushioned connection between the transmission and the motor shaft. It attaches to the direct-drive transmission and the motor shaft. If this part is defective it will affect the agitator in your washer because of its direct connection with the motor. Your washer may not agitate, spin slowly, or not spin at all. The coupling must be replaced when there is no longer a consistent connection between the transmission and the motor shaft. The coupling can wear over time because of its location between two major parts of the dryer. It is subject to material fatigue over time from normal use, or breakage caused by frequent overloading. The part measures approximately 2 inches in diameter, and is constructed of plastic and metal. This model comes in black/white.

Replacing your Whirlpool Washer Direct Drive Motor Coupling

Customer Repair Stories

Broken Coupling

1. Removed hoses from the pump

2. Removed Wiring harness from the motor

3. Unscrewed saftey screws from both clamps which hold the motor against the motor bracket.

4. Using a screw driver I easily removed/pryed the clamps from the motor.

5. I then removed the broken plastic coupler from the motor sha ... Read more ft and installed the new one coupler.

6. I did the same thing on the clutch side.

7. I set the Rubber coupler in clutch side.

8. Put motor back on until couplers joined together.

9. Placed Brackets back on Motor (patience here).

10. screwed back saftey screws on clamps.

11. connected hoses back.

Thats it... 45 minutes at most .. Save me from having to buy a new easher. I was convinced I was going to have too until I peeked underneatch the washer and saw the rubber coupler on the ground...

-

Hugo from Frisco, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers, Socket set

No movement from Basket & agitator

First take off the water pump by removing the two clips that hold it in place. Place a shallow pan under the pump to catch the water that is in the pump and hoses. Open the hose clamps with a pair of pliers or channel locks (better) and slide the hoses off of the water pum ... Read more p.

The motor comes off next. Unplug the electrical connector from the motor and two wires from the capacitor. Remove the two screws holding the clamps in place and then pop off the two clamps. You will need to hold up the motor with one hand while you remove the clamps or it will fall to the floor once the clamps are removed.

One piece of the coupling assemble will be attached to the motor and the other will be attached to the gearcase drive shaft. If you want to clean up the mess created by the shredded rubber center piece of the coupling assembly you will have to take off the motor mounting plate. It is held on by two bolts and removing it makes installing the coupling easier but probably not necessary.

Push the back half of the coupling on to the gearcase drive shaft until the shaft is flush with the face of the coupling. Install the new rubber center piece on to the coupling then re-install the motor mounting plate. Install the other half of the coupling on to the motor shaft and lift the motor up to the coupling. You have to rotate the motor shaft by spinning the fan blades until the coupling lines up so you can slide it into the other half of the coupling. Then just reattach the motor, connectors and water pump in the reverse order of disassembly.

-

Jeff from Wayne, NJ

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers, Socket set

This kit contains one screw with rubber gasket and threaded sealant. The screw head is 7/16".

Replacing your Kenmore Washer Agitator Bolt

Customer Repair Stories

The agitator had stopped working

-

Jack from Matthews, NC

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Socket set

could not get the bottom agitator to release, so finally just left it in place, first bolt I had did not fit right so ordered one directly from your store also had to wait dor my tools to get in

-

Linda Dianne from Poteau, OK

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Socket set

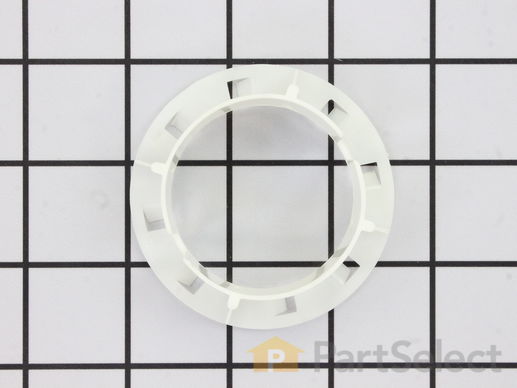

This is a genuine OEM thrust spacer for your washer, and is also commonly known as a retainer ring. The spacer is about 2.5 inches in diameter, is made of plastic, and is white in color. It is used in the agitator assembly of many direct drive washing machine models. The spacer is fitted between the agitator and the agitator auger to support it as it moves. This part is sold individually. Although it is not included in this part, you should have some dual-action agitator grease for the repair as well.

Replacing your Whirlpool Washer Thrust Spacer

Customer Repair Stories

The agiator would not work properly

-

Velma from Belvidere, IL

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Socket set

Agitator seperated from inside of wash drum

-

Larry from Brandon, FL

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Socket set

This basket drive assembly is for washers. Basket drive assembly sits on top of the transmission shaft and houses the spin basket brake mechanism. The basket drive spins to rotate the basket during the spin cycle.

Replacing your Whirlpool Washer Basket Drive Assembly with Clutch

Customer Repair Stories

The Shaft On The Direct Drive Was Worn

-

ALLEN from Newton, KS

-

Difficulty Level:Really Easy

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers, Socket set, Wrench (Adjustable), Wrench set

This part prevents the agitator shaft from leaking oil onto the transmission.

Customer Repair Stories

Slipping Spin clutch due to leaking gear-case seal.

2. Turn the water off.

3. Disconnect the supply and discharge hoses.

4. Open the cover and remove the cap/cover of the agitator. Use socket wrench to remove the bolt securing the agitator. Pull up on the agitator and remove it.

5. Lay washing machine down on it's front. Remove the inlet and outl ... Read more et drain hoses from the discharge pump.

6. Remove the 2 "faston" connectors from the motor start capacitor (looks like a D cell flashlight battery). Rock the connectors back and forth and pull gently until they come off. Polarity doesn't matter but to be safe make note of the positions.

7. Press the release clip on the motor connector and pull to disconnect it. Move the wiring harness out of harms way.

8. Remove the 3 bolt securing the motor and transmission assembly to the bottom of the tub. Pull the drive assembly out of the machine and place it on a suitable work surface.

9. Examine the tub brake assembly (still on the bottom of the tub), the clutch assembly (on the motor/transmission assembly you just removed and everything else for wear or damage. Now if you decide to proceed with repair continue with the following steps. If not you're done.

10. Remove the inverted cup washer from the agitator shaft of the assembly. Remove the "U" clip from the shaft and remove the clutch mechanism from the drive assembly. Make a sketch of the position of each of the removed components to aid in reassembly.

11. Now you can see the gear case cover and it's seal. If it is leaking (as mine was) you will need to replace it.

12. With the assembly level remove the bolts around the cover and remove the cover. Place the cover on a flat surface and with a screwdriver or punch drive the old seal out of the cover from the outside in.

13. Clean the seal area and check for damage. Clean the cover and transmission housing surfaces of old gasket material. There is a factory sealant available for reassembly but I chose an automotive RTF @ $4 vs $24 and it worked OK.

14. Installing the seal requires some tools and experience to done successfully. The right size sockets or piece of pipe, coupled with an arbor press or vise will get the seal in. The cover is delicate so if in doubt find a machine shop.

15. Support the outside of the cover on a hard surface and with a socket or short pipe length, PRESS (don't hammer) the new seal into the gear case cover.

16. Make sure there is lubricant in the gear case. Not overflowing but maybe 1/2 full when view with cover off on a level surface.

17. Apply some RTV sealant to trhe cover and install it. Tighten bolts evenly. Light torque (1-2 ft-lb).

18. Reassemble washing machine and test for leaks and proper operation.

-

Thomas from Pascoag, RI

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers, Socket set