Parts That Fix Amana Dryer NED7200TW10 Noisy

Noisy is a commonly reported symptom for the NED7200TW10 Amana Dryer, and we have put together a full guide on how to fix this. This advice is based on feedback from people who own this exact appliance. We have listed the most common parts for your NED7200TW10 Amana Dryer that will fix Noisy. We have included repair instructions, and helpful step-by-step video tutorials. If you are experiencing this issue, not to worry, DIYers just like you have fixed this, and shared their experience to help you!

Sold individually.

Customer Repair Stories

Bumpung or pounding sound.

It only takes a Phillips screwdriver and very little time. It’s a very little investment for your peace of mind.

-

Don from TAYLOR, AZ

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

Drum support roller failed

-

Candance from hillsboro, OR

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers, Wrench (Adjustable)

This idler pulley assembly is sourced from the original manufacturer for use in dryers. The assembly includes the pulley wheel and bracket. It is found near the motor where it provides tension to the dryer belt, allowing it to rotate the drum during the drying cycle. Over time, the pulley wheel and its bearings can wear out leading to squeaking and grinding noises when the drum rotates. The bracket or pulley wheel can also fall out of alignment which can damage the belt and cause it to slip off. Eventually, a faulty idler pulley assembly will prevent the drum from rotating altogether. Depending on your dryer model, you may need to disassemble the dryer to access the pulley assembly. Remove the dryer belt from the idler pulley wheel and detach the assembly from the dryer frame. Position the new assembly in its place and secure it in position. Thread the belt over the pulley and around the dryer drum, ensuring that the grooved side lays flat against the drum. Manually spin the drum to check that the belt is properly tensioned and reassemble your appliance.

Replacing your Samsung Dryer Idler Pulley Assembly

Customer Repair Stories

Dryer would not spin

Cost of part to fix - about $50.

... Read more />Repairman - didn't even ask. Would probably be $300-400.

Cost of replacement $1,000.

I rated the repair "A bit difficult" only because this is the first time I have ever repaired an appliance. If I were to repair this one again, I'd rate it as Easy.

I'm really thankful for the PartSelect video. This makes DIY repairs possible.

Thanks.

-

John from EARLYSVILLE, VA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Screw drivers

Tension/Dead Man Wheel Broke/Shattered

Pulled top of dryer off; noticed the belt was loose but not broken.

Went in through the back (1 screw and removed the exhaust pipe/plate); noticed the wheel was broken and thus the belt had fallen off.

Ordered replacement wheel/arm.

One screw to remove ol ... Read more d one, one screw to install new one...tentioned the belt. Dryer was good as new.

-

Noah from OXFORD, KS

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

Also called Roller.

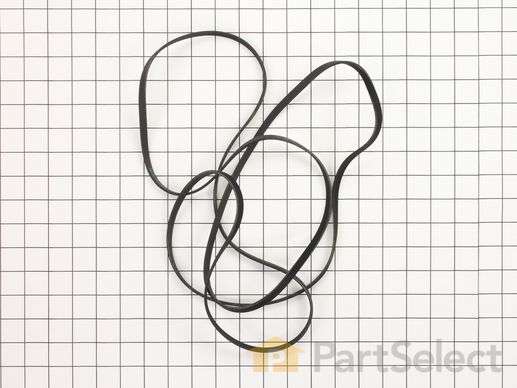

This drive belt is made to slip on the motor pulley to bring the basket up to the speed required and this makes the belt get wear and tear.

Customer Repair Stories

Just replace the belt

app thanks.

-

Alice & Jose from LAMESA, TX

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Screw drivers

This clamp is used to secure the drive motor.

Customer Repair Stories

Dryer drum wouldn't turn and motor would shut off

-

Cynthia M from Westfield, MA

-

Difficulty Level:Easy

-

Total Repair Time:More than 2 hours

-

Tools:Screw drivers