SAV3655AWW Maytag Washer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Washing machine made squeaking noise

Brake pad kit does not come with installation instructions even though it says it does. Remove bottom front panel from washer. There are three brake pads. One of mine (the right one) broke into three pieces and was found on the bottom of the washer. This is how I identified what was wrong. Run the washing machine on the handwash extra light cycle (you could use another cycle, I used this one because I believe it is the shortest), there is a point in the cycle where the disk clamping the brake pads separates from the brake pads and allows you to remove and replace the pads. During other parts of the cycle, the disk is clamped onto the brakes and you could not remove or install a brake pad. I removed the two black hose on the bottom right to get to the right brake pad. Have a 2 gallon bucket ready to collect the water if you did run the washer as above. With difficulty, I was also able to reach around the back side of the right brake pad. I used a socket wrench set. I then removed and replaced the left brake pad. I left the rear brake pad in place. I was not able to get to it.

Parts Used:

-

Peter from Littleton, CO

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Socket set, Wrench set

11 of 15 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

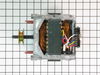

motor would't work

first i removed the 4 screws that hold the motor in place.pull the motor out and disconnected the wires ,remove the belt from the pulley, when motor was out the work was very easy 3 more bolts that hold another element in place and the rest was piece of cake ...done thanks to parts select for send me the right part at first time i recomended and i received my motor in just 3 days.congratulation

Parts Used:

-

CARLOS from MIAMI, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers, Socket set

12 of 18 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

washer would not finish cycle

replaced timer, be careful not to try to pull the outer knob off without prying out the center of it and then removing the retainer.Then you can remove the 3 piece adjusment knob that sets your washing cycles. If you do not remove it this way you will damage the timer.

Parts Used:

-

david from jasper, AR

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

10 of 12 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The thin walled plastic drain line got a pin hole leak

The washer is four years old.

This is the second time I needed to replace this same drain hose on this same washer since I had the machine

There is only my wife ant myself maybe, 2 -3 medium size loads per week - why I would have two drain lines develop the same problem in almost the same location in two years is disconcerting

There must be a design problem with the clear plastic hose - Suggest Maytag go to a thick walled rubber hose

The hole is alway inside the washer on the bottom just after the hose bracket - I suspect that something rubbing causing a small pin hole to develop - when the condition first starts it is very difficult to located -There will be water under the washer

Run the washer and discharge the water - to locate

The replacement must be made through the lower front removable panel - and is easier to do if the pump return hose is also disconnected from the pump

Be very carful with the thin wall replacement hose - very light weight plastic - do not pull across the floor of washer - it could easily get damaged

Your company did a get job getting the part to me - The Fed Ex track system was great

I could tell exactly where the delivery was al all times -

This is the second time I needed to replace this same drain hose on this same washer since I had the machine

There is only my wife ant myself maybe, 2 -3 medium size loads per week - why I would have two drain lines develop the same problem in almost the same location in two years is disconcerting

There must be a design problem with the clear plastic hose - Suggest Maytag go to a thick walled rubber hose

The hole is alway inside the washer on the bottom just after the hose bracket - I suspect that something rubbing causing a small pin hole to develop - when the condition first starts it is very difficult to located -There will be water under the washer

Run the washer and discharge the water - to locate

The replacement must be made through the lower front removable panel - and is easier to do if the pump return hose is also disconnected from the pump

Be very carful with the thin wall replacement hose - very light weight plastic - do not pull across the floor of washer - it could easily get damaged

Your company did a get job getting the part to me - The Fed Ex track system was great

I could tell exactly where the delivery was al all times -

Parts Used:

-

WALTER from Holualoa, Hawaii, AL

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Wrench set

9 of 10 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Machine stopped spinning the water out after wash cycle. The timer would advance, but the original wash water was still in tub at the end of the cycle.

The repair was super easy and fast. I removed the back of the control panel with screwdrivers (3 flat head screws, 3 phillips head screws). Then I removed the front of the knob from the timer by removing the plastic center cover cap, plactic inner clip and lifting out the inner ring. The timer was secured by only one screw, which I removed. The wiring assembly was easy to unplug. Then I popped out the timer by sliding it to the left to clear the clips. I replaced the old timer with the new one, secured the single screw, plugged the wire assembly in, reseated the timer knob on front and replaced the control panel cover. The problem was solved and the machine works like new.

Parts Used:

-

David from Thomaston, CT

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver, Screw drivers

8 of 9 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Would not empty water

I suggest if you are replacing the pump, order the belt at the same time, you must remove the pump to replace the belt.

Parts Used:

-

James from Houma, LA

-

Difficulty Level:Really Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers

8 of 9 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Would go through cycle without hitting the spin cycle

removed screws from back - took off knob on the front of the timer. I then unplugged the old timer and plugged the new one in.

It was very easy

It was very easy

Parts Used:

-

gerald from sarasota, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver

8 of 9 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Auger was broken

Needed a medium extension and a rachet a screw driver and a 13mm socket. I used a short screw driver and inserted in it the softer container and lifted it strait up to get the softner container out of the way. I used the medium extension to reach in the auger and loosen the small bolt holding the auger on the machine. Pulled it up and out. Reversed the above procedure and it was set to go. Total time about 8 to 10 minutes. Thank for all the help Kudos to all including Susan W.

Parts Used:

-

Charles F from Brooklyn, OH

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers, Socket set

7 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Water constantly leaking in tub after cycles were complete.

Unplugged electric cord from wall receptical, pulled drain hose out of wall drain, removed both water hoses from back of washer, unscrewed the metal plate that is around the water outlets from the back of the washer first and then from the valve itself. I pulled the part as far out of the washer as I could and removed the wire connectors from hot and cold side of valve, then used pliers to loosen clamp from around the rubber hose coming from inside the washer making sure not to drop the clamp down into the backside of the washer. Repeated all of those steps in reverse to reconnect the new valve and shizzam! No more leaking inside the tub when cycles are complete! Who says a girl can't fend for herself? Once again..thank you to "PartSelect" for guiding me in the right direction and saving us a lot of money :)

Parts Used:

-

Sharie from Panama City, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

7 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Old agitator broke

Removed old agitator, and installed new one. Very easy.

Parts Used:

-

Johan from Kingsford, MI

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Wrench set

9 of 13 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Unbearable Noise at spin cycle

Not only very loud at spin cycle, but started to leak water as well. Pulled lower front panel off and ran a load of clothes while laying on the floor with flashlight watching. Sure enough, water spraying out from outer tub bearing area.

Remove top front panel, sides and top, disconnect hoses and unplug wires at top of control panel, there is a plug in there. Now you should just have base unit and tub exposed so you have plenty of room to work. Next joy is to remove agitator. This is where my fun began. After removing fabric softner dispenser from top of agitator, I could not see bolt holding it on. There was a long plastic rod sticking up which looked like part of the agitator itself, so went online to a repairmans site and they said simply pull that rod out and bolt will be under it. Paid 24 bucks to them and still could not remove rod, ended up going thru slots in side of agitator with a small chisel and cutting it off, then took a 3/4" hole saw and drilled hole in top of agitator, its only about 1/8" thick and what do you know, THERE is the bolt!!!!!!! Removed bolt and out comes agitator. Next, remove cap from outer tub, take 4 bolts out of inner tub, remove inner tub. Next, remove plastic nut from shaft, I tried this with channelocks and could not budge it, ended up splitting nut with chisel and slightly damaged threads on shaft which I cleaned up easily with 60 degree thread file. Be very careful if you use this method. You can use channelocks to reinstall, just clamp on the unfinned part of nut.Take out the lint filter and throw in garbage, do not reinstall!!!!!! That filter is part of the reason tub bearing goes out!! Next, remove aluminum hub from shaft, mine was already loose so was easy. If yours is tight, screw in one of the old inner tub bolts almost all the way in and use hammer and punch to loosen. You can do the same for new one. Next, remove 6 bolts from outer tub and pull outer tub off shaft.Flip outer tub upside down and gently pry bearing out, mine came out easy as was spinning inside tub bearing fit. After cleaning everything I used Scotchseal 800 industrial sealant because bearing fit was loose. I made a clamp out of 1x2 wood and a long 1/4" bolt to hold bearing in tub to prevent it from pushing out, sometimes the sealant will cause this to happen, then I let it setup for 24 hours. Put it all back together, no leaks and SUPER quiet. Be sure and check your bottom bearing too while you have it all torn down, mine was fine. Do not forget to change O ring on spline shaft before reinstalling agitator. As far as the hole I drilled in agitator, just tapped it 1/2" pipe and screwed in a plastic pipe plug. You will need an extension and a 5/8" 12 point socket to do this.

Remove top front panel, sides and top, disconnect hoses and unplug wires at top of control panel, there is a plug in there. Now you should just have base unit and tub exposed so you have plenty of room to work. Next joy is to remove agitator. This is where my fun began. After removing fabric softner dispenser from top of agitator, I could not see bolt holding it on. There was a long plastic rod sticking up which looked like part of the agitator itself, so went online to a repairmans site and they said simply pull that rod out and bolt will be under it. Paid 24 bucks to them and still could not remove rod, ended up going thru slots in side of agitator with a small chisel and cutting it off, then took a 3/4" hole saw and drilled hole in top of agitator, its only about 1/8" thick and what do you know, THERE is the bolt!!!!!!! Removed bolt and out comes agitator. Next, remove cap from outer tub, take 4 bolts out of inner tub, remove inner tub. Next, remove plastic nut from shaft, I tried this with channelocks and could not budge it, ended up splitting nut with chisel and slightly damaged threads on shaft which I cleaned up easily with 60 degree thread file. Be very careful if you use this method. You can use channelocks to reinstall, just clamp on the unfinned part of nut.Take out the lint filter and throw in garbage, do not reinstall!!!!!! That filter is part of the reason tub bearing goes out!! Next, remove aluminum hub from shaft, mine was already loose so was easy. If yours is tight, screw in one of the old inner tub bolts almost all the way in and use hammer and punch to loosen. You can do the same for new one. Next, remove 6 bolts from outer tub and pull outer tub off shaft.Flip outer tub upside down and gently pry bearing out, mine came out easy as was spinning inside tub bearing fit. After cleaning everything I used Scotchseal 800 industrial sealant because bearing fit was loose. I made a clamp out of 1x2 wood and a long 1/4" bolt to hold bearing in tub to prevent it from pushing out, sometimes the sealant will cause this to happen, then I let it setup for 24 hours. Put it all back together, no leaks and SUPER quiet. Be sure and check your bottom bearing too while you have it all torn down, mine was fine. Do not forget to change O ring on spline shaft before reinstalling agitator. As far as the hole I drilled in agitator, just tapped it 1/2" pipe and screwed in a plastic pipe plug. You will need an extension and a 5/8" 12 point socket to do this.

Parts Used:

-

Gregory from St Helens, OR

-

Difficulty Level:Easy

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set

7 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Leaking Water And Load Noise From Drum Bearing

Following on-line instructions for the dis-assembly. Replaced bearing and seals for outer drum bearing and cleaned and lubed assembly.

Parts Used:

-

RALPH from Eugene, OR

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers, Socket set

8 of 10 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer leaking water from the bottom.

Removed front panel.

Released 2 springs on belt tensioner.

Rolled drive belt off pulleys.

Unscrewed 4 bolts holding washer motor assembly.

Tilted motor to get at pump screws.

Removed 3 pump screws and pump slid right off shaft.

Aligned new pump and reinstalled screws.

Set motor assembly loosely in place.

Rolled drive belt onto pulleys.

Re-attached tension springs.

Installed motor assembly bolts.

Re-installed front panel.

** I should have replaced drive belt at same time, but it is working with no leaks.

Released 2 springs on belt tensioner.

Rolled drive belt off pulleys.

Unscrewed 4 bolts holding washer motor assembly.

Tilted motor to get at pump screws.

Removed 3 pump screws and pump slid right off shaft.

Aligned new pump and reinstalled screws.

Set motor assembly loosely in place.

Rolled drive belt onto pulleys.

Re-attached tension springs.

Installed motor assembly bolts.

Re-installed front panel.

** I should have replaced drive belt at same time, but it is working with no leaks.

Parts Used:

-

Donald from Sierra Vista, AZ

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Socket set

7 of 8 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

replace rubber drain hose adapter

Place black rubber adapter on the end of the drain hose and stick in the stand pipe drain. That's all.

Parts Used:

-

Frank from Austin, TX

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

7 of 8 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washe would not spin clothes or agitate well

Pulled motor, as the belt will not come off unless you take to water pump off off the motor. Installed new idler wheel, washers, clips and belt. Reinstalled motor.

Works good and hopefully lasts a long time!

Works good and hopefully lasts a long time!

Parts Used:

-

Berry from Mt Sidney, VA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers, Socket set

8 of 11 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!