CDE850 - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Just ugly this time`

It's wonderful to get accessories for this 20 year old Jenn-Air. I love it and now it looks like new.

Parts Used:

-

Susan from Chino, AL

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

22 of 24 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer Not Heating

This repair was so easy a sleeping Turtle could do it. You just remove the wiring from the old unit and remember which wire is on which terminal. Easily remove the old unit and replace it. Reattach the wires and you are done! Maytag is a very easy unit to work with. Just remember if you ever have to replace your Terminal Block, don't forget to order the brass nuts to attach the wires. Regular nuts will overheat and cause a fire hazard.

Parts Used:

-

Timothy from Prairieville, LA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver, Screw drivers

22 of 25 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Oven Door hinge is broken

One oven door hinge spring was broken. I ordered two hinges to complete the repair.

The repair could not have been easier. I removed the door from the oven an unscrewed the outer frame of the door from the inner door assembly. I unscrewed the old hinge assembly and replaced them with the two new hinges.

I set the door back on the oven and replaced the oven door retaining hardware.

After replacing the retaining hardware, I removed the temporary shipping pins that keep the spring assembly static. Very important: don’t remove these hinge pins until the door is on the oven an the oven retaining hardware is secured.

The repair could not have been easier. I removed the door from the oven an unscrewed the outer frame of the door from the inner door assembly. I unscrewed the old hinge assembly and replaced them with the two new hinges.

I set the door back on the oven and replaced the oven door retaining hardware.

After replacing the retaining hardware, I removed the temporary shipping pins that keep the spring assembly static. Very important: don’t remove these hinge pins until the door is on the oven an the oven retaining hardware is secured.

Parts Used:

-

Hugh from Hopewell, NJ

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

22 of 26 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

No heat on dry cycle. Thought it might be element.

Opened top of dryer and found high limit thermostat burned in half. Thermostat is located on top of element. Replacement of thermostat took less than 10 minutes, using phillips head screwdriver.

Parts Used:

-

Thomas from Battleboro, NC

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

24 of 34 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Replaced belt while I was in there replacing motor

If you were to do the Belt Replacement only, here is the quick synopsis:

1. Unplug dryer;

2a. Open lint door on top of dryer and remove the two phillips head screws that hold the lint bay to the metal dryer top;

2b. Next remove the two brakets holding the metal top to the dryer back (one screw on each bracket);

3. Use a flat-blade screw driver to pry off the top of the dryer (leaving the timer and start button area attached);

4. Lift off top and push back to expose just enough area so you can get to the two screws holding the dryer sides to the dryer front;

5. Unplug door switch;

6. Unscrew screws from #4;

7. With door open, lift dryer front (only about an inch) and then pry bottom of dryer front from dryer sides. The bottom of the dryer front is not screwed, just siting on Front Panel Clips;

8. Once the front is off the dryer, simply remove the belt and install the new one. Please note that while you are in here, you may want to inspect the rear drum seal and replace if it is worn to the point where metal is rubbing on metal. This is also a good time to clean out dust from inside this cavity to help extend the life of the bearings on the rollers and prevent dust from accumulating and gunking up the motor, etc.

9. Re-assemble tin the opposite order.

If you have any mechanical sense at all and you don't know anything about dryers, you will be surprised at the simplicity of the dryer.

1. Unplug dryer;

2a. Open lint door on top of dryer and remove the two phillips head screws that hold the lint bay to the metal dryer top;

2b. Next remove the two brakets holding the metal top to the dryer back (one screw on each bracket);

3. Use a flat-blade screw driver to pry off the top of the dryer (leaving the timer and start button area attached);

4. Lift off top and push back to expose just enough area so you can get to the two screws holding the dryer sides to the dryer front;

5. Unplug door switch;

6. Unscrew screws from #4;

7. With door open, lift dryer front (only about an inch) and then pry bottom of dryer front from dryer sides. The bottom of the dryer front is not screwed, just siting on Front Panel Clips;

8. Once the front is off the dryer, simply remove the belt and install the new one. Please note that while you are in here, you may want to inspect the rear drum seal and replace if it is worn to the point where metal is rubbing on metal. This is also a good time to clean out dust from inside this cavity to help extend the life of the bearings on the rollers and prevent dust from accumulating and gunking up the motor, etc.

9. Re-assemble tin the opposite order.

If you have any mechanical sense at all and you don't know anything about dryers, you will be surprised at the simplicity of the dryer.

Parts Used:

-

Douglas from COMMERCE, TX

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers, Wrench (Adjustable)

20 of 24 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Oven Door wouldn't fully close and light stayed on.

Remove oven door by removing chrome flat plate that holds the hinge in place (one screw at each hinge) and LIFT door off oven. There is a hole in the hinge that you can stick a small nail through to hold the hinge in the "partially open" position for easier removal and replacement of the door (I didn't know this until I received the new hinges, which have a removeable pin in the hole.) After door is off, remove three screws each, on the top and bottom of door, to remove the back half of door and expose the hinges. Remove one screw from bottom of door that holds bottom of hinge in place. Lift out hinge bottom and unhook top of hinge. Reverse process to reassemble. Remove small pins by opening oven door fully. The new hinges did solve the problem. You have to order two hinges for each door. They are NOT sold as pairs.

Parts Used:

-

Jeff from Fremont, CA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

18 of 20 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The top would not heat,large or small eye.

Removed the bottom cover and replaced the burned contact spade. Cleaned the wires and adjust the contact holder.

Parts Used:

-

Calvin from Merced, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Pliers

27 of 47 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Infinite switch ran more than one burner

Purchased 1 infinite switch and installed it on the left front burner. problem still there so I used the switch that I replaced on the rear burner and all was ok. The front switch had been sending full heat to the rear burner,but the problem ended up with the rear switch. The switches are interconnected and all are the same part number.Diagrams on partsselect were the key to a successful repair.To access the switch you need only to remove the fan cover, remove the 2 screws holding the switch assembly and move it foreward and then lift to reveal slide on connectors. Power to the unit is off at the main panel during the entire process.

Parts Used:

-

Stephen from Andover, MA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

31 of 59 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Other collector broke and was tearing clothing

Opened the top by popping the two fasteners holding it down. Did this with a screw driver. Took two screws out of the front holding collector in place and two screws out holding the front to the two other sides. Put front of dryer down on the floor. Removed old collector and used all other existing material from old collector to finish job. Wife could not believe how quick this was. Put back together was a snap too.

Parts Used:

-

Michael from Bloomington, IL

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

19 of 24 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

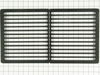

Old Jenn--Air cook top inop. Model discontinued

Our Jenn-Air cook top is 25 years old. One can no longer order parts for this old of model. We ordered new SS burners as well as new Burner cartridge terminal blocks for a new and current model. They work perfectly. Took 10 minutes. $ 350 dollars verses $ 2600 for a new JennAir range plus instillation. Unit looks and works great. Plan to order new switches next.

Parts Used:

-

Ronald from Avon, CO

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

20 of 27 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

dryer was making a thump sound when drying clothes or when it came to a stop

My husband and I used a screwdriver to pry open the top of the dryer, then unscrewed the two front corners of it from the inside. Next, we disconnected wires attached to front lid, then pulled the big barrel of the dryer away from the rest of it. We put a new drum roller wheel on the left side and greased the inside perimeter of it. Next, we took off the old cushion set, and stuck on the newer set, and greased drum glide as well. Lastly, we took off the "old" belt, and replaced it with the one we purchased from PartSelect. We forgot how the old one came off the pulley, but after much trial and error, we figured it out in a snap! (this is why this project took us longer than we expected)

In conclusion, this company for parts is wonderful and I have been referring them to all of my friends!

In conclusion, this company for parts is wonderful and I have been referring them to all of my friends!

Parts Used:

-

andrea from west reading, PA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers

17 of 19 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer Would Not Shut Off On Its Own

Ordered my part from partselect. Com (even easier than installation) unpluged the dryer,removed all knobs from face plate ,removed three phillips head screws across top ,removed two 5/16 head screws from timer( behind cycle knob) tilted back face plate unpluged one wire at atime from old timer placed back on new timer then reverced the process. Problem solved

Parts Used:

-

johnny from london, KY

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

18 of 22 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer not getting clothes dry in one cycle

Raise the top of the dryer. This exposed the elements in the back. Removed old elements,paying attention to where the wires go.

Installed new elements, hooked the wires up, and I was done.

Installed new elements, hooked the wires up, and I was done.

Parts Used:

-

Ray from Raphine, VA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver

18 of 23 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer would not heat.

First I unplugged the dryer and slid it a few inches out from the wall. I slid 2 putty knives in the front top about 3 inches in from the sides. Released the top and raised it up. I used a multimeter to test the hi limit and the element, both were operational. I used a screwdriver to remove the 2 screws that hold the front panel in place. I lowered the panel slightly and disconnected the wires mentally noting the proper placement. With the front panel on the floor, the problem was obvious. I cleaned the lint clog under the lint screen that had caused the issue to begin with.I used a shop vac and cleaned the vent area as well as the front panel. I used a nut driver to remove the 2 screws that held the thermostat in place. The old thermostat fell apart in my hands. I covered the bare exposed wires with electrical tape. ( must have gotten HOT) and reattached the connections to the new thermostat, then replaced the 2 screws that held it secure. I stood the front panel back up and reattached the electrical connections and the 2 screws. I lowered the top and plugged it back into the outlet. I turned it on. It works like new.

Parts Used:

-

Deb from Milford, OH

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

17 of 20 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dual element burner only stays on high

The replacement switch was not exactly as my original and none of the other instructions matched exactly with my unit. So I had to figure it out, but they matched mostly what Micheal from Colliervile wrote. Safety is paramount. Turn off circuit breaker and ensure there is no power to unit with a test light. You don't have to remove the glass top. Open oven door and remove 4 screws at bottom of control panel, then remove two screws on each end while suppoting the panel with one hand. Rest control panel on top of door or hang by wires. Remove two screws to detach switch from panel. I took pictures of the wire placement on old switch and drew a diagram of what color wire went to each terminal. I used the instruction sheet diagram of new switch and marked where each wire color goes. Here is where I put them: DOUBLE BLACK to L1,2; New jumper from P1 to S1; RED to 2: DOUBLE RED to P2; new jumper with small connector from S2 to "element on" indicator lamp (it's longer than and replaces existing jumper); YELLOW to 4a; TAN to 4. The letters in parenthesis on the instruction sheet almost matched up to my old switch so I used them to help with the placement. I didn't have to seperate any compound red wires. Double check wire placement and put it all back together in reverse order.

Parts Used:

-

Sherman from Perry, GA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Pliers, Screw drivers

17 of 21 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!