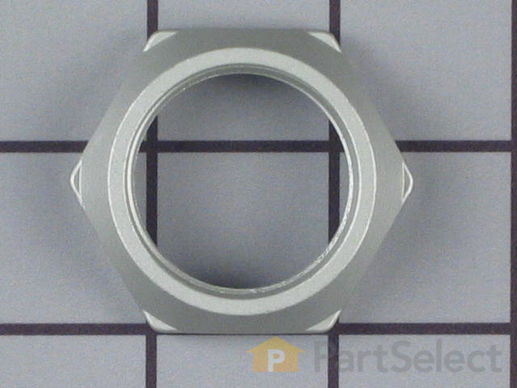

Hub Nut WH2X1193

Rated by 40 customers

A Bit Difficult

More than 2 hours

Ratings submitted by customers like you who bought this part.

Get this part fast! Average delivery time for in-stock parts via standard shipping: 1.8 days.

Hub Nut Specifications

How Buying OEM Parts Can Save You Time and Money

Replacing your General Electric Washer Hub Nut

-

5 Stars 6

-

4 Stars 0

-

3 Stars 0

-

2 Stars 0

-

1 Star 0

- < Prev

- 1

- Next >

- < Prev

- 1

- Next >

- < Prev

- 1

- 2

- 3

- Next >

-

Dennis from NOBLESVILLE, IN

-

Difficulty Level:Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set, Wrench (Adjustable)

Spent most time reading the help stories and gathering up tools. My concern was getting the bad parts out and that hub nut without more damage. Finally found a 1924 vintage 9" monkey wrench I forgot I had and it fit just fine for putting it back together. I put a 1/8" bit in the drill and put a hole in center of nut next to the flats about 1/8" down by 3 of the flats. Wacked the nut in 2 locations with the chisel in the unwind direction with the corner of the chisel in the hole to put a grove on the nut so to keep away from damaging trans shaft. It finally came off in 3 pieces.

After pulling the basket stuck a rag in the drain hole. The basket sounds like it has water in it but its the counter weight attached on top. Brushed up the crud on trans shaft and sponged out the remaining water and other particles.

Next was a pump inspection. If you take the input line off you can see the impeller to remove any stuff that may damage it. Have to un-bolt the pump be careful on the wiring to pump trying to unplug the wires may damage the connectors or even worse the pump. I mostly had crud in the water on the line.

Ordered the needed parts, and cleaned up the tub, reinstalled the pump. After the parts arrived took about a 1/2 hour to put it in service again. Don't forget to wack the hub nut on tight when installing so it wont come off in use.

Many thanks to all in sharing their story it helped me out to see what to expect.

-

MICHAEL from ARLINGTON HTS, IL

-

Difficulty Level:Really Easy

-

Total Repair Time:More than 2 hours

-

Tools:Pliers, Socket set, Wrench (Adjustable)

-

Keith from LAS VEGAS, NV

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Socket set, Wrench (Adjustable)

-

Tatsuhito from S HUNTINGTON, NY

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers, Socket set, Wrench (Adjustable)

-

Eugene from BALLSTON SPA, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set, Wrench (Adjustable), Wrench set

-

Daryll from MURRYSVILLE, PA

-

Difficulty Level:Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set, Wrench (Adjustable), Wrench set

-

Tom from VERMILLION, SD

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

William from COMMERCE TWP, MI

-

Difficulty Level:Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set, Wrench (Adjustable), Wrench set

-

Paul from HOLTWOOD, PA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Screw drivers, Socket set, Wrench (Adjustable)

-

Steve from VALPARAISO, IN

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Screw drivers, Socket set

- < Prev

- 1

- 2

- 3

- Next >

Ask our experts a question about this part and we'll get back to you as soon as possible!

- < Prev

- 1

- 2

- Next >

10 people found this helpful.

5 people found this helpful.

3 people found this helpful.

2 people found this helpful.

1 person found this helpful.

1 person found this helpful.

1 person found this helpful.

- < Prev

- 1

- 2

- Next >

Manufacturer Part Number: WH2X1193

Item is in stock and will ship today if your order is placed before 4:00 PM Eastern Standard Time.

If your order is placed after 4:00 PM EST, the in stock items will ship on the next business day.

Item is not in stock and usually ships 3-5 business days from the time you place your order.

Item is not in stock and usually ships 10-15 business days from the time you place your order.

This item is no longer being made by the manufacturer, and cannot be added to your shopping cart.