DLG2 - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

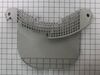

Other collector broke and was tearing clothing

Opened the top by popping the two fasteners holding it down. Did this with a screw driver. Took two screws out of the front holding collector in place and two screws out holding the front to the two other sides. Put front of dryer down on the floor. Removed old collector and used all other existing material from old collector to finish job. Wife could not believe how quick this was. Put back together was a snap too.

Parts Used:

-

Michael from Bloomington, IL

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

19 of 24 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

We have ruined hundreds and thousands of dollars the past decade on our LG typical detective lint filter!

I watched a You Tube Video. It instructed me to take the top, front, and door off. Not necessary!!! But definitely unplug it as there is a moisture sensor attached inside this housing. Remove current Filter. Remove all screws holding the two key pieces in (Filter Cover and Guide). Disconnect the moisture sensor (mine is white wires connected to two metal prongs). Remove the Filter Cover and Filter Guide and discard. Get a long vaccum hose and remove all visible lint in the area below where the Filter Guide resides. Replace the Filter Guide and reconnect the moisture sensor, replace the Filter Cover. You may find it easier to snap these two pieces together before installing. Make sure the small plastic guides on the inside of the drum snap in tightly to the tei guide holes, then replace all screws. Note- Part Select does not send screws, so save your screws from the old parts and take note which are longer and go where. Tighten, but do not over tighten. If you were successful, the Filter Cover and Guide should be smooth with the edge of the drum and door. Install your new Filter, plug back in, and enjoy! I can FINALLY dry tank tops, open shoulder, and key hole tops, as well as sheets without my dryer eating them. Only problem is that I wish I had done it sooner. Note, I'm a female with no electrical or appliance repair experience. I did this on my lunch break and surprised my husband when he got home! Easy peasy!

Parts Used:

-

Stephanie from CLINTON, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

17 of 18 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

dryer was making a thump sound when drying clothes or when it came to a stop

My husband and I used a screwdriver to pry open the top of the dryer, then unscrewed the two front corners of it from the inside. Next, we disconnected wires attached to front lid, then pulled the big barrel of the dryer away from the rest of it. We put a new drum roller wheel on the left side and greased the inside perimeter of it. Next, we took off the old cushion set, and stuck on the newer set, and greased drum glide as well. Lastly, we took off the "old" belt, and replaced it with the one we purchased from PartSelect. We forgot how the old one came off the pulley, but after much trial and error, we figured it out in a snap! (this is why this project took us longer than we expected)

In conclusion, this company for parts is wonderful and I have been referring them to all of my friends!

In conclusion, this company for parts is wonderful and I have been referring them to all of my friends!

Parts Used:

-

andrea from west reading, PA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers

17 of 19 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer Would Not Shut Off On Its Own

Ordered my part from partselect. Com (even easier than installation) unpluged the dryer,removed all knobs from face plate ,removed three phillips head screws across top ,removed two 5/16 head screws from timer( behind cycle knob) tilted back face plate unpluged one wire at atime from old timer placed back on new timer then reverced the process. Problem solved

Parts Used:

-

johnny from london, KY

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

18 of 22 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Replaced old belt & the igniter

I removed the 2 screws that hold the ignighter & cover in place...unpluged the wire...replaced it with the new ignighter...thats when I found out that it was easier to take off than to put on...but I got it back into place...replaced the 2 screws...put the new belt on the drum...fitted it around the moter...pulled the wheel spring back to get it on tight...made sure the drum was fitted around the wheels...checked the tension...plugged in the wire for the ignighter...tested to see if the ignighter glowed...it did...I but the door back on the dryer...and it works...i thank my father for showing me how to work on machines...instead of letting me play with my dolls...thank you Parts select for getting my order to me in great condition & record time...

Parts Used:

-

Terri from Palmdale, CA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:15 - 30 mins

-

Tools:Socket set, Wrench (Adjustable)

16 of 18 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer stopped working in the middle of a cycle

First off, the parts were exactly what I needed and arrived at my front door in less than 48 hours.

The repair was quite easy. 1. access the "guts" by popping the two clipps and open top panel like a car hood.2. remove the high temp doohickie with a nut driver, one screw, two wires.3. Remove the heating element from its mount. 4. remove the high temp fuse doohickie, By popping off its wires and little retaining bracket. 5. do steps (in this order) 5-1 replacing new parts. 6. spend three hours looking for the dryer brush, you know you have somewhere, to clean 5 years of accumulated lint out of the lint trap.7. drive to Ace, by dryer brush. 8. (most important step) clean the lint trap, or be forced to repeat steps 1-5. 9. Pop a cold one and relish the peace and quiet, devoid of spousal nagging to fix the damn dryer. 10. Take down clothesline in backyard.

The repair was quite easy. 1. access the "guts" by popping the two clipps and open top panel like a car hood.2. remove the high temp doohickie with a nut driver, one screw, two wires.3. Remove the heating element from its mount. 4. remove the high temp fuse doohickie, By popping off its wires and little retaining bracket. 5. do steps (in this order) 5-1 replacing new parts. 6. spend three hours looking for the dryer brush, you know you have somewhere, to clean 5 years of accumulated lint out of the lint trap.7. drive to Ace, by dryer brush. 8. (most important step) clean the lint trap, or be forced to repeat steps 1-5. 9. Pop a cold one and relish the peace and quiet, devoid of spousal nagging to fix the damn dryer. 10. Take down clothesline in backyard.

Parts Used:

-

justin from navarre, FL

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Pliers, Screw drivers

14 of 14 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Noisy and Ineffective Drying Cycle due to Damaged Blower Wheel

0. Opened packaged and receipt verified the parts against the drawing and packing slip.

1. Disconnected dryer from power source by pulling the plug.

2. Removed the two screws (philips) on left and right side of the main frame to allow access to the blower assembly.

3. (Optional)Verified power dead at the circuitry near the blower wheel assembly (former navy electrician- "check it dead").

4. Removed the two screws at the base of the wheel cover using the screw driver (philips). The other screws on the assembly cover required the use of a 1/4" nut driver.

5. Opened the assembly, and with a flathead, pried the Retaining Omega ring, and removed the damaged wheel (broken vanes and missing straight end of the center ring) and disposed.

6. Inserted the new wheel on the shaft and was able to manually do it until about 3/4 of the way; to get it fully insert it, tap it with a mallet (tap the center of the wheel and avoid the blades).

7. Insert the retaining ring and operationally test it by manually rotating the tumbler and verifying the blower wheel moves freely and without noises.

8. (Optional) Vacuumed the lint and dust from the wheel assembly, the filter and exhaust line (found several broken pieces of vanes there). Inspected heater assembly for obvious signs of damage

9. Re-installed the assembly cover and the main cover back to the frame

10. Reconnected the plug to outlet and tested by a starting a 10 minutes cycle- no noise and constant flow of air.

11. Smoked a Motecristo Churchill as I grilled the steaks and pondered the greatness of the free market.

,

1. Disconnected dryer from power source by pulling the plug.

2. Removed the two screws (philips) on left and right side of the main frame to allow access to the blower assembly.

3. (Optional)Verified power dead at the circuitry near the blower wheel assembly (former navy electrician- "check it dead").

4. Removed the two screws at the base of the wheel cover using the screw driver (philips). The other screws on the assembly cover required the use of a 1/4" nut driver.

5. Opened the assembly, and with a flathead, pried the Retaining Omega ring, and removed the damaged wheel (broken vanes and missing straight end of the center ring) and disposed.

6. Inserted the new wheel on the shaft and was able to manually do it until about 3/4 of the way; to get it fully insert it, tap it with a mallet (tap the center of the wheel and avoid the blades).

7. Insert the retaining ring and operationally test it by manually rotating the tumbler and verifying the blower wheel moves freely and without noises.

8. (Optional) Vacuumed the lint and dust from the wheel assembly, the filter and exhaust line (found several broken pieces of vanes there). Inspected heater assembly for obvious signs of damage

9. Re-installed the assembly cover and the main cover back to the frame

10. Reconnected the plug to outlet and tested by a starting a 10 minutes cycle- no noise and constant flow of air.

11. Smoked a Motecristo Churchill as I grilled the steaks and pondered the greatness of the free market.

,

Parts Used:

-

John from Webster City, IA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

14 of 14 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Gas Dryer not getting hot

I noticed the flame would start, then quit after about 15 seconds. I checked the flame detector, and found the lenze cracked. I replaced it, and it's as good as gold.

It looked like a hard job to take the drum out to get at the part. But the top was off with 3 screws, the front about 6 I think. Then the front frame, only 4 screws. I think setting the belt tentioner was the hardest thing to do.

Done in 45 minutes, both the job, then the next load of laundry.

It looked like a hard job to take the drum out to get at the part. But the top was off with 3 screws, the front about 6 I think. Then the front frame, only 4 screws. I think setting the belt tentioner was the hardest thing to do.

Done in 45 minutes, both the job, then the next load of laundry.

Parts Used:

-

Terry from Goose Creek, SC

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

21 of 35 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Door Catch was broken

I just inserted the door catch, which by the way fit in perfectly. Thanks. Took 5 seconds to repair.

Parts Used:

-

Inocencio from Edinburg, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

14 of 15 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Time clock not moving .Not enough heat

Opened front panel .Tested both coils on gas valve.

Found no continuity on one of the coils. Replaced coil,

dryer works like new.

Found no continuity on one of the coils. Replaced coil,

dryer works like new.

Parts Used:

-

PHILIP from LONG ISLAND CITY, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers, Screw drivers

16 of 21 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Change dryer belt

I opened up the dryer as per the instructions I had received from PartSelect tech support. It was very easy to do. The only unexpected thing was that the original belt had snapped and in doing so the idler pulley was actually laying on the floor of the dryer's bottom. I had to figure out how it went, but that only took a minute and I popped it back into place. I held the drum by hand while pulling the dryer face away so it wouldn't fall and then I slipped the belt over the drum and quickly closed the front up again. I aligned the belt on the spot where the old one had been, pulled it through the idler pulley and over the motor and voila. Done. I closed up the dryer and was on to another "Honey Do" project within 20 minutes.

Parts Used:

-

Scott from Bayport, NY

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

14 of 16 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Very noisy when running

We bought 2 roller wheels to replace the ones up front that turn the drum. We watched a video prior to ordering the parts, then followed along with it as we did the repair. It was really easy to complete, with the hardest part being getting some of the screws to loosen at first. Now it purrs like a kitten. We are so happy to have silences the racket. One wheel was completely worn away, with shreds of rubber sitting inside the cabinet.

Parts Used:

-

CAROLYN from LEBANON, TN

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set

15 of 19 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Lint screen and frame was torn up

Was initially going to order just the lint screen. Manufacturer notes said that there had been a redesign on that part so ordered all three pieces to ensure matching parts. On arrival it was just a matter of removing a few screws. Direct fit replacement!

Parts Used:

-

Clifford from HUNTINGTN BCH, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

15 of 19 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer went dead during a load and needed to replace the fuses.

Very easy repair. Just needed to remove some screws to access the heating element area. The fuses are (1) just above the elements and (2) to the right side of them (if facing from the front). Alittle loosening with a philips screwdriver, removing blown fuses, replace with new fuses, tighten new fuses in place, replace outer screws and job done. Also made sure to fully clean lint collection area. I had a good amount stuck in there and it restricted air flow which caused the fuses to blow. It took 6 years worth of drying to make it happen.

Parts Used:

-

Andy from Lawrenceville, GA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

13 of 14 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Burner would not go on on my Stack Set Dryer

Took out two front Panel screws and removed the panel. Removed Gas solenoid coil holding bracket by removing two phillips head screws. Disconnected the coil leads. and removed the coils. Connected the new coils to the leads and set in place. Replaced the holding bracket and the two screws. Replaced the front cover and the two front cover screws. Piece of Cake!

Parts Used:

-

Robert from North East, PA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

16 of 24 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!