JDR8895AAS Jenn-Air Range - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

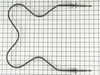

Lower element in oven burned out

When the element failed, it continued to glow nearly white-hot and slowly burned along a spiral path on the element. I figured this MUST be due to a voltage leak - the control was OFF on the range.

I shut off the breaker, removed the two screws where the element goes through the back of the oven, pulled the element forward and pulled the wires off of the element. (Found it handy to twist the wire connectors outward to prevent the wires from slipping through the back of the oven.)

A new element won't "fit" exactly but you can easily push it into position to get the screw holes to line up. Total time was less than 15 minutes.

I shut off the breaker, removed the two screws where the element goes through the back of the oven, pulled the element forward and pulled the wires off of the element. (Found it handy to twist the wire connectors outward to prevent the wires from slipping through the back of the oven.)

A new element won't "fit" exactly but you can easily push it into position to get the screw holes to line up. Total time was less than 15 minutes.

Parts Used:

-

Tom from Plainwell, MI

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

4 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

door seal contaminated by a boil-over, not flexible

From reading other reviews i thought I would have to dis-assemble the door but when I saw the new part I realized I would not have to, simply pop the beveled clips w/pocket knife and pop in the new seal clips. the ends tucked very nicely, an 80+ yr. old would have no trouble if they had their wits.

Parts Used:

-

Rob from Yakima, WA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Top Oven Element broke

Ordered the part from your company. It arrived promptly. Gave to to my two sons 22 & 29. They fixed it.

Very easy........................................

Very easy........................................

Parts Used:

-

Susan from Doylestown, PA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers, Screw drivers

4 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

broken oven door inner glass pane.

Remove the door, remove screws from all sides

Remove sides and face of oven door by sliding down from under the oven handle trim.

Remove screws on 2nd light of glass and set aside.

Now you are at the inner door panes. their should be two in an insulated type unit.

Remove the remaining screws from the handle pracket and the permiter frame for the glass/insulation. Remove permiter frame and set aside.

Pull out inner door glass frame. get a pair of pliers and bend tab on frame up so you can pull the frame sightly apart, replace the glass, secure frame tightly around glass slide tab back into reciever slot and bend down ( you may need another person to assist in keeping both lights in the frame while trying to ben tab back in to place)

reassemble door as it came apart carefull not to over tighten the screws, they strip easy.

Remove sides and face of oven door by sliding down from under the oven handle trim.

Remove screws on 2nd light of glass and set aside.

Now you are at the inner door panes. their should be two in an insulated type unit.

Remove the remaining screws from the handle pracket and the permiter frame for the glass/insulation. Remove permiter frame and set aside.

Pull out inner door glass frame. get a pair of pliers and bend tab on frame up so you can pull the frame sightly apart, replace the glass, secure frame tightly around glass slide tab back into reciever slot and bend down ( you may need another person to assist in keeping both lights in the frame while trying to ben tab back in to place)

reassemble door as it came apart carefull not to over tighten the screws, they strip easy.

Parts Used:

-

Adam from modesto, CA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers

4 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

broiler element broke

removed screws and disconnected the wires removed element and did the replacement less than 15 minutes, and cost less than locally by 25.00 and received part the next day. EXCELLENT

Parts Used:

-

michael from Norwich, CT

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

4 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Gasket was worn out.

-

Michael from VALLEJO, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

ovens wouldn't maintain temperature after preheat cycle

unplugged oven. removed 2 screws that hold the sensor in place, then removed the dozen or so screws that hold on the rear panel, unplugged sensor and fed wire through insulation. identified and installed correct harness adapter then fed new wire and connecter through insulation and connected to adapter. installed sensor retaining screws.plugged oven back in and tested function.no dice. unplugged oven once again. removed oven control panel and upon inspection of printed circuit board discovered 3 solder joints had failed. dang. resoldered failed joints and also sweetened up a few others that looked suspect. reinstalled controller, replaced all retaining hardware, and plugged in the oven. tah-dah!! works like a charm now. moral of the story is check the pc board first and save $50 for unneeded pats!!! or buy the controller from parts direct for $260ish. btw a roll of solder and soldering iron from an auto parts store cost around $10, learned to solder on you-tube $0. amazing all the home appliances yo can fix if you're not afraid to take a few screws out and poke around a bit. CHEERS!

Parts Used:

-

sherri from elk horn, IA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Inner glass pane broke during self-cleaning operation

I removed all the screws that held the trim and inner frame to the outside window unit first. Then, I removed a protective glass from over the two inner panes. Next after removing the frame that held the two inner glass panes together, I took the broken inner glass pane out and replaced it with the new one. Then basically I just retraced my steps and had the door put back together in about 45 minutes. You just need to pay close attention to your disassembly so that you are able to put the pieces back together quickly.

Parts Used:

-

Mark from Abingdon, VA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

4 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

cracked internal alumn gas supply tube

Pull oven power and turn off gas (mine was off)

remove six screw that hold the back cover

lift the back cover off and set aside

The tube runs from the regulator to the burner valve assembly (manifold?). Un-tighten the two ends gently and remove old tube.

Apply LP gas leak goo to the threads (don't use teflon tape) Align the new tube and finger tighten the nuts. Make sure you get at good seat on the connector by pressing snuggly (not too hard) the tube end into the recieving unit and then carefully tighten with the wrench until it is snug.

Be careful and turn on gas valve.

Listen for leaks. (turn off gas valve if leak found)

retighten a little more and re-check. If still leaks you have other problems like cross threaded nut or a bad seat. I would order a new part if that is the case or call someone with more experience.

If no leaks, replace the back panel and the 6 screws. Plug the power cord back in and give it a test run. At first there will be air in the line so it may take a moment for enough gas to reach the burner.

For the courious, I bent it when I lifted the burner top up to peek under to fix a differnt problem with the ignighter. Note to self: Un hook the tube first if you need to look under the burner unit. :)

remove six screw that hold the back cover

lift the back cover off and set aside

The tube runs from the regulator to the burner valve assembly (manifold?). Un-tighten the two ends gently and remove old tube.

Apply LP gas leak goo to the threads (don't use teflon tape) Align the new tube and finger tighten the nuts. Make sure you get at good seat on the connector by pressing snuggly (not too hard) the tube end into the recieving unit and then carefully tighten with the wrench until it is snug.

Be careful and turn on gas valve.

Listen for leaks. (turn off gas valve if leak found)

retighten a little more and re-check. If still leaks you have other problems like cross threaded nut or a bad seat. I would order a new part if that is the case or call someone with more experience.

If no leaks, replace the back panel and the 6 screws. Plug the power cord back in and give it a test run. At first there will be air in the line so it may take a moment for enough gas to reach the burner.

For the courious, I bent it when I lifted the burner top up to peek under to fix a differnt problem with the ignighter. Note to self: Un hook the tube first if you need to look under the burner unit. :)

Parts Used:

-

Paul Shaw from KIrkland, WA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Wrench (Adjustable)

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Broil element non functional

Power turned off. Door of the oven lifted off. Four screws removed, old element pulled out to reveal electrical connectors. Wires easily removed, and element discarded. New element connected to the two conductors, four screws installed and the job was completed.

Very easy. Took about 10 minutes.

Very easy. Took about 10 minutes.

Parts Used:

-

Clifford A from Melbourne Beach, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Replaced heating element

Easier than making a pie! Unscrewed 4 screws and detached the element from the back of the small upper oven. Connected the new element and put the 4 screws back in place. We saved $129 service fee by doing this ourselves not to mention the markup on parts. Shipping was very quick! While I hope to not have to do this again...I would do it again in a split second!

Parts Used:

-

tracy from north attleboro, MA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Oven heat loss, door gasket needed replacement

The entire "project" took me less than 3 minutes, and required no tools at all! First, the saleswoman over the phone pointed me to the correct product for my problem ($30 less than what I thought I needed), and it arrived at my home within 4 days. Then, it was just a matter of pulling off the old gasket, and snapping the new one in place! Simple!

Parts Used:

-

Stephen from Chapell Hill, NC

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

After cleaning, F1-1 error flashed and neither oven worked

First I called a repairman and left a message. That was 3 weeks ago. So, I 'googled' the error message and determined what part I thought I needed. Ordered the part on Wednesday evening and it was there when I got home from work on Friday. I unpacked the part, got a phillips screwdriver and then watched the repair video on your website. About 20 minutes later I pushed my stove back in place and the flashing said 'set time'. Then I checked both ovens, and have since used both, and everything works!!

Parts Used:

-

Georgene from Rock City, IL

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

3 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Replace the oven Sensor

The sensor is mounted in the top right side of the oven.An extra long screw driver helps to avoid damage to the sensor when replacing it.The connectors were the opposite to the old sensor and I did not see that there were adapter cables included. It might help to connect or tie these together as I only expected the sensor and did not look for adapters.I had cut the wires and used wire nuts when I found the adapters.The repairs works fine.

Mike

Mike

Parts Used:

-

Michael from Exeter, NH

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Pliers, Screw drivers

3 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Shattered inside glass when attempted to self-clean

Door was removed very easily. Outside trim pieces were removed. The rest came apart like a simple puzzle. Inside glass is very easily accessed. Upon assembling, time was well under an hour. Shipping was fantastic and I saved close to 200dollars between a service call and a repair.

Parts Used:

-

John from East Sandwich, MA

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

3 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!