FDB1050REC2 Frigidaire Dishwasher - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Leaking Door

Pulled out old gasket from bottom of door with needle nosed pliers and then put in new one in.

Parts Used:

-

Robert from Clinton, OH

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers

21 of 26 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

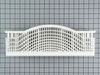

large holes in the bottom of the basket where pieces of plastic kept breaking off

I replaced the basket. No tools necessary. New basket seems sturdier than original. Very satisfied with my purchase.

Parts Used:

-

Lauren from Peabody, MA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

18 of 21 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Lower spray arm came off and melted against the heating element

I installed the new spray arm without any tools and it worked perfectly.

Parts Used:

-

Lisa from Fort Lauderdale, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

20 of 28 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Door spring had broken; door would fall open

Removed the bottom panel on the unit (2 screws hold it on) and pulled the dishwasher out about 4"--after turning off electricity to the unit. Removed the broken spring and the old linkage and replaced them with the new parts. Pushed the diswasher back into place, and replaced the bottom panel. Turned on the electricity and the diswasher door is "good as new." This is quite simple to do; just takes patience.

Parts Used:

-

Sue from Weymouth, MA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

16 of 16 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

One of the springs was broken, The door would not open or close properly. There was also a leak coming from the front of the dishwasher.

I removed the dishwasher from the cabinet space (two screws) and manually replaced both springs. I replaced one spring first to see if there would be an improvement when the second new spring was installed. There was much better tension once the second new spring was added.That is why changing both springs is recommended. This was very easy.

Changing the gasket was scary because I thought the the whole door would have to be taken apart. You know nothing ever goes back together the same. I feared that I would create an even bigger leak than what I had. Taken the door apart didnt work for me, so I just pulled the old gasket by hand and pressed in the new one. I made sure that it was seated correctly. Voila no leak.

The dishwasher is running as good as new.

I ordered these parts on Friday morning. They were on my door step Monday morning,

I highly recommend ordering from this site.

Changing the gasket was scary because I thought the the whole door would have to be taken apart. You know nothing ever goes back together the same. I feared that I would create an even bigger leak than what I had. Taken the door apart didnt work for me, so I just pulled the old gasket by hand and pressed in the new one. I made sure that it was seated correctly. Voila no leak.

The dishwasher is running as good as new.

I ordered these parts on Friday morning. They were on my door step Monday morning,

I highly recommend ordering from this site.

Parts Used:

-

Ron from Montclair, NJ

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers

17 of 19 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

No water was coming into dishwasher.

Unscrewed dishwasher from cabinet and pulled out about 1 foot. Took bottom plate off of dishwasher. Undid clamp on hose of discharge of inlet water valve and removed hose. Shut off water to water inlet valve and removed. Took wiring clip off of water inlet valve. Removed 2 screws holding water inlet valve in place. Installed new water inlet valve in reverse order.

Parts Used:

-

Jeffery from Excelsior Springs, MO

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers, Wrench (Adjustable)

19 of 25 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

water leak right bottom corner

Fully open dishwasher door to horizontal position, remove lower dishwasher rack and relocate to another temp location, grab old lower door seal from right or left corner and pull completely out of door, lay the old bottom seal aside facing the same direction as once installed (seal has a notched side which faces the right side of door), match direction of the new seal with the old seal (match the notched side of seal to the right side of door), gently push the seal into the door starting on the right side (notched side of seal fits tightly into a receiving area inside the door), and finally push the remaining portion of the seal into door (aligning with the right side already properly seated inside dishwasher door). Close dishwasher and run water cycle to confirm leak.

Parts Used:

-

Grant from Fairview, TN

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

17 of 20 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

old spray arm had melted and wasnt spraying

I removed the old spray arm by pulling it off of the base then I pushed the new one on and made sure it was on properly then I pit the base back into the dishwasher and it was good as new!

Parts Used:

-

shannon from baltimore, MD

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

18 of 23 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Drain Motor would not run

I remove the 5 or 6 screws that hold the plastic decorative top front cover in place (the screws are on the inside of the door). Lifted and pulled the cover off of the door. Pushing in the two side clips, detached the control module power/control connector from the door. Removed two screws that hold the control module to the cover, then released the snapping clips that hold the control model in place. Reversed all the steps and ran a test cycle. It worked! Thanks PS!

Parts Used:

-

Jonathan from Stamford, CT

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

16 of 18 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Diswasher would not drain with a staticky sound.

Pulled the dishwasher out and laid it on its back. From under the dishwasher I unscrewed three screws and freed the drain pump from some sort of frame. Then with the pliers loosed the orange clamp that held the black hose to it. Then unscrewed the clamp that held the white hose to it. Then pulled out the purple and white fuse wires. These wires were very tight I used pliers to get them off. The pump was free. Be sure to have a bowl to catch all the water. There wasn't a lot but it stinks. Then put it all together the way I took it apart. The dishwasher works perfectly now.

Parts Used:

-

Brenda from Orem, UT

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers

16 of 18 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

heater element burnt out (black spot)

Make sure power is off. Remove metal toe kick with fillips screw driver. Reach under dishwasher with 1/2" open

end wrench and completly unscrew brass nuts from element ends. Then open door and pull element ends straight up. Note: As you pull element ends up (inside washer) you are also forcing the element end wire connectors to come off underneath. The electricial connectors are very hard to get off any other way.

Wendell Hensley

Madiso0nville, Tn

end wrench and completly unscrew brass nuts from element ends. Then open door and pull element ends straight up. Note: As you pull element ends up (inside washer) you are also forcing the element end wire connectors to come off underneath. The electricial connectors are very hard to get off any other way.

Wendell Hensley

Madiso0nville, Tn

Parts Used:

-

Wendell from Madisonville, TN

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Wrench set

16 of 19 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

dishwasher racks had become old and plastic coating came off.

All I had to do was take out old racks and replace with new ones. However the top rack did require taking off the part where the water runs through, it was easy though.

I would like to comment on how quickly and efficiently the parts arrived. I placed my order on a monday morning and am pleased to report by tuesday afternoon they arrived, much to my delight.

I would like to comment on how quickly and efficiently the parts arrived. I placed my order on a monday morning and am pleased to report by tuesday afternoon they arrived, much to my delight.

Parts Used:

-

PAMELA from PORT ST LUCIE, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

16 of 19 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Heating coil went bad

I had to remove the dishwasher from under the counter. I then had to unscrew (from the bottom) the bolts that held the heater in place. After that I ran into a problem of disconnecting the wires that ran to the heater. I did not want to "force" the wires off and I was unsure how exactly to remove them. I figured out that they are really hard to pull off but there are no clips holding them on, so you won't break anything off. Once I got the wires off, I was able to screw the nuts onto the new heater and put it back into place.

Parts Used:

-

Ryan from Alton, IL

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Wrench set

15 of 17 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

No Water Circulating in Wash or Rinse Cycle

Removed the dishwasher from under the counter, and ran to diagnose the problem. Drain pump ran, but circulating motor did not. Ordered the replacement circ pump / motor assy, and slid the washer back in its hole.

When the new motor arrived, I slid it back out, disconnected everything, and drained the water from the bottom. Then I tipped the washer on its side, removed the old motor and installed the new one following included instructions. I did have to use the new wiring harness, and found the new one had only two leads where the original had three. I connected the blue and white leads, and left the original green loose.

All in all, it was an easy repair that could be done by anyone with a basic set of skills.

When the new motor arrived, I slid it back out, disconnected everything, and drained the water from the bottom. Then I tipped the washer on its side, removed the old motor and installed the new one following included instructions. I did have to use the new wiring harness, and found the new one had only two leads where the original had three. I connected the blue and white leads, and left the original green loose.

All in all, it was an easy repair that could be done by anyone with a basic set of skills.

Parts Used:

-

Rod from Bandon, OR

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers, Wrench (Adjustable)

14 of 15 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Upper spray arm kept falling during cycle

Place spray arm into receptacle. Take nut and screw on being careful not to over tighten. This will strip the spray arm and the same problem will occur. Easy fix!

Parts Used:

-

ALAN from REDDING, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

21 of 37 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!