DDC4580BCL General Electric Dryer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Broken belt, also replaced front slide and rear drum bearing

Remove the Torx screws along the front top edge and flipped the top back. Removed two screws at the top inside holding the front panel on. Loosened two screws at the front bottom and took the front panel off. Pulled the drum out the front. I gave everything a good vacuuming with a shop vac and a long handle brush. Then went around back, removed the access panel, removed the rear drum bearing plate and installed the new one. Removed the rear bearing from the back of the drum and installed the new one (You have to work from both sides of the drum which makes it a little tricky.I used a couple of wire ties to hold everything in place while I lined everything up. Screws or punches would work too). The front drum slides are held in by 2 screws each and you could replace them without removing the drum. They need to be lubed with the lubricant supplied. I put the drum partially in then looped the belt over the narrow back part of the drum, around the motor pulley and idler pulley. Put the drum all the way in and the belt onto the drum by rotating it by hand. The belt ribs go against the drum. Installing the belt was the a little tricky but not impossible. It could be easier if you loosen the left side panel to give you some room to reach in but I was able to do it without doing that. Threw the front and top back on and was done. Total time was about 1.5 hours a lot of which was spent getting the dryer in and out of the little cubby hole it lives it.

Parts Used:

-

Thomas from Webster, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers, Socket set

Was this instruction helpful to you?

Thank you for voting!

Replacing Igniter

I was disappointed that there were No Instructions included with the part. So I found a you-tube video that wlked me through it...Took off back of dryer, then the top, then the front to get to the igniter...could not pull out the part, so I had to reach in and replace it while it was in the dryer. It Works!

Parts Used:

-

Leesa from Columbus, OH

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers, Socket set, Wrench (Adjustable)

Was this instruction helpful to you?

Thank you for voting!

Defective rear drum bearing

Removed drum, replaced bearing. Installed new belt. Reinstalled drum. No problem

Parts Used:

-

Donald from Alden, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Wrench set

Was this instruction helpful to you?

Thank you for voting!

Dryer drum not turning

I removed the top of the dryer and verified the broken belt. Since the dryer is almost 20 years old, I decided to go a little further just to make sure that was all that was wrong. After I removed the drum I found the rear drum bearing worn. The parts were here in a couple days!Replacing the parts took about an hour. Getting the drum to line up with the three mounting holes was the hardest. I took three machine screws the same pitch but longer, cut the heads off them and used them as alignment pins. Now my dryer is quieter than it has been in years, all for less than 20 dollars including shipping!!

Parts Used:

-

Marc from Stamford, NY

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Socket set

Was this instruction helpful to you?

Thank you for voting!

Loud screeching noise

I watched video supplied from parts select, only took about 30 minutes, hardest part was putting belt back on, couldn't fit hands in easily, but once I did it, dryer is like new, can't hear a thing.

Parts Used:

-

Michael from Hopatcong, NJ

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

Was this instruction helpful to you?

Thank you for voting!

Noise, poor drying

I noticed the original blower wheel was worn, the hole for the motor shaft was reamed out and the blower was not spinning with the motor. Air was not being circulated so the clothes were not drying well. Replacing the wheel was relatively easy. I did see other people commenting on the difficulty of getting the drive belt re installed properly. I noticed a small "lip" bent into the motor frame, and found the arm for the belt tensioner would fit into this lip and it held it out of the way while I reinstalled the drum and reouted the belt onto the motor pulley. Once the belt was in place, I gently let the tensioner out of its holding position and everything went back into place nicely.

Parts Used:

-

Robert from Wyandotte, MI

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set

Was this instruction helpful to you?

Thank you for voting!

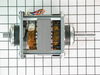

Loud Noise coming from dryer (like motor was going out)

I had to take the top panel off of the dryer which is 2 screws inside the dryer door jam. Then the front panel had to come off which was 2 screws inside the dryer above the tumbler. One on each side. Then it lifts off of two hooks at the bottom. Then the left panel (left if you are looking at the front of the dryer) had to come off which was a few screws on the back, a few on the front, and one on the bottom. Once I had the panels off, I unscrewed the blower wheel which is one screw. I took the blower wheel cabinet loose but didn't remove it. There is a metal collar that holds the motor to the bracket. Pull it off from the top. Unplug all the wires attached to the motor. I took a picture of the wire connections with my phone for reference with the new motor. Remove the belt. The motor should pull out towards you. The new motor comes with a pulley. Put the pulley on the motor and tighten locking screw. Put new motor in dryer and replace the metal collar. Connect all wire connections. Reconnect the blower wheel and tighten all screws to the blower wheel housing. Now, I plugged the dryer back in and tested it without reattaching the belt. Know that if you do it this way, the dryer will not stay on because there is a relay switch that is engaged only when the belt is on the pulley and there is tension on the belt tensioner. When the dryer motor worked properly, I replaced the belt and put all the panels back on. Plugged it up and it worked beautifully.

Parts Used:

-

Chad from New Bern, NC

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

Was this instruction helpful to you?

Thank you for voting!

The drum bearing worn and dryer squeaking.

The info from your web site was helpful. I had never taken a dryer apart and the instructions made the job easy. Used socket set to remove the back panel and top control panel. Then used a phillip's screwdriver to remove the two screws that hold the top of the dryer; these screws are accessed by opening the door to the dryer. To remove the front of the dryer remove to the two screws that are located at the top upper corners where front panel meet the side panel. Once these two screws are removed, remove the belt from around the drum and lift the drum out. The drum bearing is located on the back of the drum; remove the remnants of the old bearing and replace it with the new one. Retrace your steps to put the dryer back together. To get the belt back on track you will have to remove the lower back panel to access the belt drive and tension pulley. It is not difficult. God bless you.

Parts Used:

-

jesse from Denison, TX

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Socket set, Wrench set

Was this instruction helpful to you?

Thank you for voting!

original equipment belt-drive broke

disassembled chassis of dryer, unbolted top, lifted top to expose drum. bolted top back on. resumed repair next morning. unbolted top. lifted drum (it moved up and down about 1 inch) and got new belt around it. rebolted top down. tipped dryer to its back. unbolted and removed panel at bottom, exposing drive motor and tensioner spring. positioned belt around drive motor spindle and tensioner spring. replaced panel. reconnected dryer to electricity. reconnected gas using new flexible connector.

Parts Used:

-

james from chicago, IL

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Screw drivers, Wrench set

Was this instruction helpful to you?

Thank you for voting!

dryer door would not stay closed

-

Dave from Redondo Beach, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

Was this instruction helpful to you?

Thank you for voting!

The main symptom was a burning smell that got on the clothes and the dryer was somewhat louder than it had been.

Researching on the web I thought the trouble might be lint buildup or trouble w/ one of the parts involved in spinning the drum. However I cleaned out all the lint and replaced the belt and idler pulley and this didn't improve the smell (drum bearing was fine). I then concluded the trouble was the motor. Running the motor w/o the drum in place confirmed this was where the noise/smell was coming from. Replacing the motor was fiddly--I had to remove the clip holding the motor (pried the top w/ a screwdriver), wires (made a diagram so as to put back in same order, they were hard to get off--a pliers did the job), clamps holding the motor on the duct, the motor mount, the duct, the fan. Putting all this back together took a while (not hard just fiddly). Tested the motor w/out the drum in place and it sounded fine. Put the drum and back/front/top panels back and the dryer runs fine now. All parts came quickly and exactly matched the parts in my 1993 Hotpoint dryer. As others have said the pulley kit is not needed--these are included w/ the motor. BTW I am a 53-year-old lady. Thanks to all who took the time to write up their experiences--big help!!

Parts Used:

-

Kristin from Bellevue, WA

-

Difficulty Level:Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Pliers, Screw drivers, Socket set

Was this instruction helpful to you?

Thank you for voting!

The dryer was making a very loud noise

After having a friend who repairs appliances come and diagnose the problem, I was able to find the parts I needed very easily at PartSelect. They came quickly and I removed the front panel, followed the instructions (they were not very detailed) and also had help reading some of the other posts from people on the website. I replaced the parts and the dryer is now quiet and running fine.

Parts Used:

-

Jana from Eatonton, GA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver, Screw drivers

Was this instruction helpful to you?

Thank you for voting!

Dryer was making a vibrating sound near the bottom left rear area.

I suspected the idler pulley shaft was worn. I found the repalcement pulley on parts select web site. finding the part was very easy and delivery was very quick. After removing the dryer from the wall,I removed the access panel in the rear which exposed the motor, belt, and pulley. After removing the belt from the pulley, I removed the pully assembly from the dryer. I removed the keeper retaining ring on the pulley and installed the new pulley with the new parts supplied. The new pulley assembly was then ready for re-installation.

Parts Used:

-

RICHARD from ST. MARTINVILLE, LA

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers

Was this instruction helpful to you?

Thank you for voting!

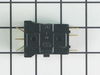

Dryer would not start and the smell of an electrical part burning.

What to do if you have a load of wet laundry at 23:00, the dryer won’t start, and you have no spare start switch.

Removed rear access panel and discovered the wire from terminal #2 (goes to heater coils) on the start switch had melted and disconnected. The start switch showed signs of overheating but not melted. Removed the switch and found the switch’s actuator button was jammed in the ‘in’ position (dryer won't start). The switch was a friendly one in that it was possible to disassemble it. Most switches today are molded/glued together, but this one could be pried apart. The contacts inside were still in fair condition and, after dressing them, the switch was reassembled. The actuator button had a burr that was filed off and the switch action worked fine. All of the 1/4" male QC contacts on the switch were cleaned with a wire brush. The burned wire was cut back about 6” and a new piece of 14ga wire was spliced in with a wire nut. A new 1/4” QC terminal was crimped to the wire and all wires were re-attached to the switch.

This fix would probably last for a long time to come, but I bought a new switch and installed it and will keep the old switch as a backup.

p.s. The load of laundry was dry by 02:00.

Removed rear access panel and discovered the wire from terminal #2 (goes to heater coils) on the start switch had melted and disconnected. The start switch showed signs of overheating but not melted. Removed the switch and found the switch’s actuator button was jammed in the ‘in’ position (dryer won't start). The switch was a friendly one in that it was possible to disassemble it. Most switches today are molded/glued together, but this one could be pried apart. The contacts inside were still in fair condition and, after dressing them, the switch was reassembled. The actuator button had a burr that was filed off and the switch action worked fine. All of the 1/4" male QC contacts on the switch were cleaned with a wire brush. The burned wire was cut back about 6” and a new piece of 14ga wire was spliced in with a wire nut. A new 1/4” QC terminal was crimped to the wire and all wires were re-attached to the switch.

This fix would probably last for a long time to come, but I bought a new switch and installed it and will keep the old switch as a backup.

p.s. The load of laundry was dry by 02:00.

Parts Used:

-

Randy from FREMONT, CA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers

Was this instruction helpful to you?

Thank you for voting!

intermittent failure to heat air until total failure to heat

Unplugged dryer. Removed access door from lower right front of dryer. Disconnected wiring harness to igniter. Couldn't reach retaining bolt with wrench or socket, but was able to spread igniter clip with fingers to be able to remove old igniter and then work new igniter into position without unbolting retaining clip - ultimately a tool-less operation that could have taken 5 minutes. Reconnect wiring harness and reconnect power. Test dryer then replace access cover.

Parts Used:

-

James from Asbury Park, NJ

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

Was this instruction helpful to you?

Thank you for voting!