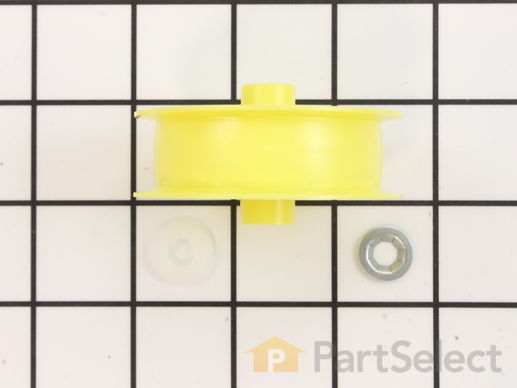

Idler Pulley Wheel WE12X81

Rated by 9 customers

Easy

1- 2 hours

Ratings submitted by customers like you who bought this part.

Get this part fast! Average delivery time for in-stock parts via standard shipping: 1.8 days.

Idler Pulley Wheel Specifications

How Buying OEM Parts Can Save You Time and Money

-

5 Stars 0

-

4 Stars 1

-

3 Stars 0

-

2 Stars 0

-

1 Star 0

- < Prev

- 1

- Next >

- < Prev

- 1

- Next >

- < Prev

- 1

- Next >

-

Carl from Montoursville, PA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

-

Barry from Dunellen, NJ

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers, Wrench set

--Relieved tension on belt by moving idler arm and moved belt off idler puller (just to the side).

--Removed e-clip.

--Removed old pulley and washers.

--Installed new thick plastic washer first, then pulley, then e-cl ... Read more ip.

--Relieve tension and place belt back on new pulley.

--Replace back panel.

-Fini!

-

Sam from Durham, PA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Pliers, Screw drivers

Laid on front put new pulley in place on back side.

Stood back up, put belt back on motor pulley.

Then put idler pully wheel back in place.

Put front back on, lid down in place, ready to run.

-

Deborah from Clarksburg, WV

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers, Socket set

The door has two screws at the bottom that need to be taken out. Once those are out there are two screws on both sides at the top h ... Read more olding it to the frame. Remove those as well.

Before you remove the front you should document the wiring for the door light switch. I took these off to give the door a little extra room so I could rest it on a toolbox without taking all the wires completely off.

Once the door is free, on the back there is a metal plate with two screws in it roughly in the middle of the unit. Unscrew the top completely but leave the bottom screw in and just slightly loosen it. This will allow it to swing down out of the way without the need to completely remove it and have one more part to put back together in the end.

What this plate is covering is the center of the drum. There is a small metal tab that you can push on and it will push the drum out so it can be removed. Gripping the drum, you can lift it out by guiding it through the notches on each side where the drum protrudes.

With the drum removed you'll see the motor and idle pulley. On my model the pulley was attached to a metal rod that was spring loaded. The pulley is held on by a small tension washer that was easily removed with pliers. Installation was somewhat more difficult but mostly just getting it lined up and started. Once on the rod it was easy to push it into place.

With the new pulley installed it's time to install the new belt. To do this first put the belt over the drop and then replace the drum back into the frame. Once the drum is pushed back into the hole it will support itself.

Now you need to remove the panel on the back to get access to the motor and pulley. This panel has a lot of screws. Once that's off you can then guide the belt over the motor and get the idle pulley to put tension on the belt.

Once that is complete just replace all the screws you removed, plug it back in and watch as your new belt moves the drum once again.

-

Thomas from Terre Haute, IN

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers, Socket set

I removed the back panel so I could slip the belt off the idler pulley. There was also a small panel covering the back of the drum bearing. I removed the clip holding the ... Read more drum bearing shaft in place. Then the entire drum assembly with the drum bearing was removed by shifting the drum toward the front and lifting it out.

I removed the drum bearing assembly by taking out the three screws holding it to the drum.

Once I received the drum bearing kit I reassembled it in reverse order.

The idler pulley had a clip holding the pulley on the shaft. I removed the clip, took off the old pulley and replaced it with the new one, replacing the clip. Then I rethreaded the drum belt around the motor shaft and ilder pulley and put the panels back on.

-

Terry from Woodstock, GA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set

Note: Lint is combustable, save yourself the disaster of a dryer fire.

Position dryer face down on floor.

Access rear of unit, vacume clean.

Upright unit.

Access front of unit by removing sheet metal screws above door to float the lid.

Using screwdriver gently s ... Read more eperate drum at top from housing. Hold open with wedges.

Thread new belt through hole a foot or so.

Tape belt to drum near drum center.

Rotate drum until belt is fully around.

Note: Taping new belt to drum will assist you in reassembling. Belt will not fall off drum when unit is face down on floor.

Remove wedges and resecure sheet metal screws to top of unit.

Place the unit face down again.

Ensure belt clears all front mounts.

Note: gentaly pull drum from mount and slide belt between.

Remove old belt and idler pully.

Note: replace the idler pully with every new belt it will save you time later.

Install new idler pulley and rethread in new belt.

Rotate drum to access and remove tape attaching new belt to drum.

Upright unit and test.

Re-attach access panels, reposition unit and

re-attach duct work.

Done

-

Mark D. from Kittery, ME

-

Difficulty Level:Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Pliers, Screw drivers, Wrench set

Dryer ran for ten mintues and then quite again. Seems to be in the motor and not the less expensive parts I found to be worn.

-

Deanna from Red Wing, MN

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers, Socket set

-

David from Gibraltar, MI

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

- < Prev

- 1

- Next >

Ask our experts a question about this part and we'll get back to you as soon as possible!

- < Prev

- 1

- Next >

3 people found this helpful.

2 people found this helpful.

- < Prev

- 1

- Next >

Manufacturer Part Number: WE12X81

Item is in stock and will ship today if your order is placed before 4:00 PM Eastern Standard Time.

If your order is placed after 4:00 PM EST, the in stock items will ship on the next business day.

Item is not in stock and usually ships 3-5 business days from the time you place your order.

Item is not in stock and usually ships 10-15 business days from the time you place your order.

This item is no longer being made by the manufacturer, and cannot be added to your shopping cart.