ATF6000ES1 Frigidaire Washer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Broken door lock assembly

Turned circuit Off at breaker panel Extracted metal seal ring from tumbler seal,loosened/extracted 2 screws holding assembly,pulled 2 wires,Reversed sequence with New lock assembly,made sure tumbler seal was seated securely,turned breaker on,tested,Complete!

Parts Used:

-

Richard from CULVER CITY, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Door was sagging so strike would not line up upon closing the door.

This part did not fully solve the problem because both halves of the door need to be replaced and the other half is neither included in this purchase or available on this web site that I can see. The door panel is thin plastic and the problem will reoccur. Removed door by removing the metal hinge screws, disassembled door, installed new part, reinstalled door.

Parts Used:

-

Paul from BOZEMAN, MT

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

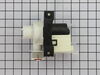

Pump motor made humming noise and wouldn't drain water from tub.

Disconnect power. Disconnect water hoses. Remove back panel. Remove top panel. Disconnect bladder ring. Disconnect control panel wire harness and control panel. Remove front panel. Disconnect hose clamps to drain hose and tub drain hose. Disconnect pump motor power supply wire. Disconnect pump screws. Now do everything in reverse replacing old pump with new.. One special note: replace factory hose clamps with new hose clamps.

Parts Used:

-

Matthew from Oakford, IL

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers, Socket set

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Would go into high spin in regular wash settings .

(1) Removed top of washer . (2) Open washer door . (3) Removed the two screws holding the Door Lock Sw while holding the switch from inside the machine . (4) Lifted the switch up to remove wire harness one wire at a time and reconnect to new switch . Double checked work and reinstalled switch . (5) Run washer machine make sure everything is back working . I need to add that the washer door needed to be adjusted . The bottom of the door was kicked out . Washer is now working .

Parts Used:

-

Larry from TOLEDO, OH

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Vane broke off inside drum

Inserted new vane into slots in the drum. I then held the front of the drum while I slid the vane tabs in place by pushing the vane to the back of the drum. Once the vane was in place, I screwed in the screw that came inside the vane kit.

Parts Used:

-

Glen from Redondo Beach, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

5 of 10 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The plastic door strike/catch had become brittle and broken off inside the door on a front loading washer.

There were only two screws that held the door strike/catch in place. I had to fish out the broken plastic piece with a pair of hemostats. The only difficult part about changing the new piece was that I had to find someone with the correct screwdriver to use since it was not a standara screwdriver. Luckily I live next door to a mechanic and borrowed his. The two screws came off easilty and I was able to replace it in 2 minutes. I was thrilled that the part that I ordered arrived the next day.

Parts Used:

-

Barbara from Lutz, FL

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

excessive vibration

I followed the instalation instructions provided with new parts. Getting the mounting pins out was relatively easy However, the shock on the right, behind the pump, was a bit more difficult to remove than the one on the left. I took the rubber drain off the pump in order to get at the pin behind the pump. The new replacement shocks came with the plastic bushings inserted in the shocks in alternate directions. The original pins were all inserted into the bracket / shocks from the rear so when I installed the new shocks I reinserted one bushing on each shock so they we both oriented in the same direction. The instruction says to be sure the mounting pin is pressed from the side with the busing collar. It seemed strange the shocks came that way, with no mention of switching them. The most difficult part on the installation was pushing the pins back through the bracket and shock since there was no easy way to push the pins in from the rear. I used a large channel locks on the left side, but the right side was more difficult with all of the obstructions. I finally was able to push in place with my bare hands but was very difficult. Sorry to say the new shocks did not cure the vibration at all. I was very careful to make sure the machine is level. I'm not sure if there is a cure other than replacing the machine.

Parts Used:

-

Jon from Holland, MI

-

Difficulty Level:Very Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers, Socket set, Wrench (Adjustable)

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

the latch broke

It was very easy. I simply unscrewed the 2 screws set the new latch into place and replaced the screws.

Parts Used:

-

Sarah from Gilford, NH

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Wouldn't start

With the help of PartSelect's diagnosting tool it was easy to find the right part. The part arrived very fast and the installation was "child's play" by following PartSelect's video. I must have saved > $100. Thank You very much. -Anna-

Parts Used:

-

Anne from Storrs, CT

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Leveling Leg Broken

The leveling legs on my Frigidaire stackable washer & dryer were broken. They are made of plastic and while moving the unit one of the legs had broke off. I ordered two replacements from PartSelect and received them within a few days. The old legs were removed by screwing them out and then the new ones were installed. Pretty easy installation for DIY. The new legs work great.

Parts Used:

-

Brian from Rochester, NH

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Wrench (Adjustable)

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

no spin cycle sometimes

pulled the retaining ring then unscrewed 2 screws removed the bad switch and unplugged the old wires then hooked them back to the new switch...this was the second switch in approximately 2 years...

Parts Used:

-

glenn from hampton, VA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

4 of 8 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer would not complete the spin cycle

I started by removing the two screws at the back of the washer and taking the top off of the washing machine. Than I removed the two screws securing the door lok and switch assembly. I disconected the two or three electrical connections and install the new one in the reverse order.

Parts Used:

-

Andrew from Fruitland, ID

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

3 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Drum vane broke

The part ordering and arrival was very easy and fast. Problem with the directions on removing the damaged drum vane. They were not clear directions. Once I figured out what needed to be done it went easy

Parts Used:

-

Robert from Boyertown, PA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

3 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The small plastic piece broke that locked the door.

-

Tami from INDIANAPOLIS, IN

-

Difficulty Level:Very Easy

-

Total Repair Time:Less than 15 mins

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer was filling with water when not in use

This repair was pretty simple. Unplug washer from electrical outlet and remove hoses. This is a good time to replace the hoses. Removed two screws at the back of the washer to remove the top of the washer. This exposed the faulty valve assembly. Disconnect the three connections. There are two screws holding this part in place. The top one is easy to remove, the bottom one is a little more difficult due to access. Remove plastic retainer plate on back of washer. Remove faulty valve assembly. There are two rubber grommets/gaskets that will need to be removed from the faulty part and installed on the new part. Slide new assembly into place. Secure with the two screws. Replace retainer plate. Reattach power connections. Reattach hoses and finally Reinstall top of washer. Total time was right around 30 minutes.

Parts Used:

-

Dan from LONE TREE, CO

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!