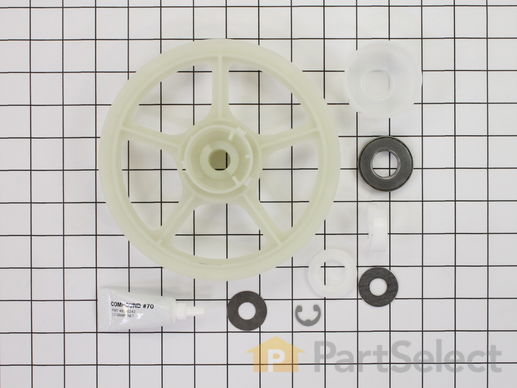

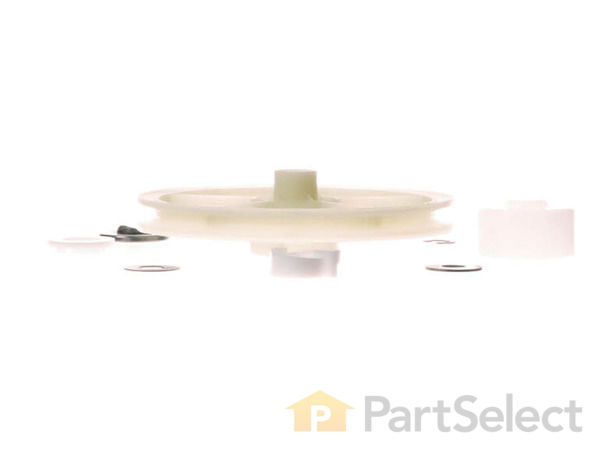

Transmission Pulley and Bearing Kit 12002213

Rated by 25 customers

Easy

1- 2 hours

Ratings submitted by customers like you who bought this part.

Get this part fast! Average delivery time for in-stock parts via standard shipping: 1.8 days.

Transmission Pulley and Bearing Kit Specifications

How Buying OEM Parts Can Save You Time and Money

Replacing your Maytag Washer Transmission Pulley and Bearing Kit

-

5 Stars 10

-

4 Stars 4

-

3 Stars 1

-

2 Stars 0

-

1 Star 1

- < Prev

- 1

- 2

- Next >

- < Prev

- 1

- 2

- Next >

- < Prev

- 1

- 2

- 3

- Next >

Replace the Transmission Pulley and Bearing Kit - 5:44

Replaced the Drive Belt 52 inches - 1:10

Also I replaced the drain pump even though it still worked, because the machine is ... Read more 19 years old.

Replace the Drain Pump video - 6:22 min.

After doing the repairs, the Maytag Atlantis washer now works fine.

-

Scott from CINCINNATI, OH

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers

-

joe from LAWRENCEVILLE, NJ

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

-

Scott from PORTAGE, PA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set, Wrench (Adjustable)

-

William B from STURGIS, MI

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set, Wrench (Adjustable)

-

Louis from FREMONT, NE

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

-

Eleanor from PALATKA, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers

-

Leo Joseph from BENSON, NC

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Pliers, Screw drivers, Socket set, Wrench set

-

john from BEACHWOOD, NJ

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set, Wrench set

-

Brian from South Holland, IL

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

-

Carlos from Georgetown, TN

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Pliers, Socket set

- < Prev

- 1

- 2

- 3

- Next >

Ask our experts a question about this part and we'll get back to you as soon as possible!

- < Prev

- 1

- 2

- 3

- Next >

13 people found this helpful.

5 people found this helpful.

2 people found this helpful.

2 people found this helpful.

2 people found this helpful.

2 people found this helpful.

2 people found this helpful.

1 person found this helpful.

1 person found this helpful.

1 person found this helpful.

- < Prev

- 1

- 2

- 3

- Next >

Manufacturer Part Number: 12002213

Item is in stock and will ship today if your order is placed before 4:00 PM Eastern Standard Time.

If your order is placed after 4:00 PM EST, the in stock items will ship on the next business day.

Item is not in stock and usually ships 3-5 business days from the time you place your order.

Item is not in stock and usually ships 10-15 business days from the time you place your order.

This item is no longer being made by the manufacturer, and cannot be added to your shopping cart.