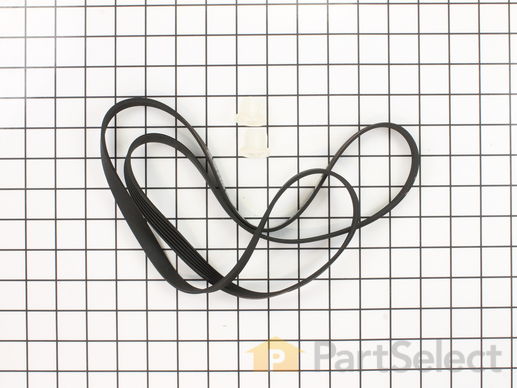

Drive Belt and Motor Isolator Kit 12001788

Rated by 14 customers

Easy

1- 2 hours

Ratings submitted by customers like you who bought this part.

Get this part fast! Average delivery time for in-stock parts via standard shipping: 1.8 days.

Drive Belt and Motor Isolator Kit Specifications

How Buying OEM Parts Can Save You Time and Money

Replacing your Maytag Washer Drive Belt and Motor Isolator Kit

-

5 Stars 4

-

4 Stars 0

-

3 Stars 0

-

2 Stars 1

-

1 Star 3

- < Prev

- 1

- Next >

- < Prev

- 1

- Next >

- < Prev

- 1

- 2

- Next >

I decided to replace the drive belt since I was into the back of the washer. The video on this site was spot on, however I did have to apply a lot of effort putting ... Read more the new one on. My old belt was stretched out considerably and at first thought I had a wrong replacement belt. Number on the belts confirmed it was correct. Just had to walk the belt on the larger pulley and it will fit.

My washer is running like a new one!

-

Craig from VAIL, AZ

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set, Wrench (Adjustable)

Thank you Bill

-

William from N LAS VEGAS, NV

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

Have a zip-tie ready.

Engage the new belt on the motor shaft pulley. The belt grooves should line up with the motor shaft grooves towards the end of the shaft. Grip the drum pulley and rotate counterclockwise while guiding the belt onto the pulley. At about 12 O'Clock, zip-tie the belt to the pulley.. then rotate ccw until installed.. (about 6 O'Clock). Snip off the zip-tie and your ready to go.

-

William from SAINT CHARLES, IL

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Socket set

-

Robert from NEW WILMNGTN, PA

-

Difficulty Level:Very Difficult

-

Total Repair Time:More than 2 hours

belt. We decided to replace anything that involved the spinning cycle while we had it all apart.

It was well worth the time and effort we put into it. It works like a chime

and is very quiet . Silence is golden ! Hopefully it will work another 18 years.

-

Loanne from W BROOKFIELD, MA

-

Difficulty Level:Really Easy

-

Total Repair Time:More than 2 hours

-

Tools:Screw drivers, Socket set, Wrench (Adjustable)

-

William from CHINA, ME

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Wrench (Adjustable)

-

David from FOLSOM, CA

-

Difficulty Level:Very Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Wrench (Adjustable)

-

Douglas from Marion, IN

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

-

richard from austin, MN

-

Difficulty Level:Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Screw drivers, Socket set

-

Brandon from Berea, OH

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

- < Prev

- 1

- 2

- Next >

Ask our experts a question about this part and we'll get back to you as soon as possible!

- < Prev

- 1

- Next >

4 people found this helpful.

4 people found this helpful.

4 people found this helpful.

- < Prev

- 1

- Next >

Manufacturer Part Number: 12001788

Item is in stock and will ship today if your order is placed before 4:00 PM Eastern Standard Time.

If your order is placed after 4:00 PM EST, the in stock items will ship on the next business day.

Item is not in stock and usually ships 3-5 business days from the time you place your order.

Item is not in stock and usually ships 10-15 business days from the time you place your order.

This item is no longer being made by the manufacturer, and cannot be added to your shopping cart.