YLTE6234DQ6 Whirlpool Washer Dryer Combo - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Slipping Spin clutch due to leaking gear-case seal.

1. Unplug the machine.

2. Turn the water off.

3. Disconnect the supply and discharge hoses.

4. Open the cover and remove the cap/cover of the agitator. Use socket wrench to remove the bolt securing the agitator. Pull up on the agitator and remove it.

5. Lay washing machine down on it's front. Remove the inlet and outlet drain hoses from the discharge pump.

6. Remove the 2 "faston" connectors from the motor start capacitor (looks like a D cell flashlight battery). Rock the connectors back and forth and pull gently until they come off. Polarity doesn't matter but to be safe make note of the positions.

7. Press the release clip on the motor connector and pull to disconnect it. Move the wiring harness out of harms way.

8. Remove the 3 bolt securing the motor and transmission assembly to the bottom of the tub. Pull the drive assembly out of the machine and place it on a suitable work surface.

9. Examine the tub brake assembly (still on the bottom of the tub), the clutch assembly (on the motor/transmission assembly you just removed and everything else for wear or damage. Now if you decide to proceed with repair continue with the following steps. If not you're done.

10. Remove the inverted cup washer from the agitator shaft of the assembly. Remove the "U" clip from the shaft and remove the clutch mechanism from the drive assembly. Make a sketch of the position of each of the removed components to aid in reassembly.

11. Now you can see the gear case cover and it's seal. If it is leaking (as mine was) you will need to replace it.

12. With the assembly level remove the bolts around the cover and remove the cover. Place the cover on a flat surface and with a screwdriver or punch drive the old seal out of the cover from the outside in.

13. Clean the seal area and check for damage. Clean the cover and transmission housing surfaces of old gasket material. There is a factory sealant available for reassembly but I chose an automotive RTF @ $4 vs $24 and it worked OK.

14. Installing the seal requires some tools and experience to done successfully. The right size sockets or piece of pipe, coupled with an arbor press or vise will get the seal in. The cover is delicate so if in doubt find a machine shop.

15. Support the outside of the cover on a hard surface and with a socket or short pipe length, PRESS (don't hammer) the new seal into the gear case cover.

16. Make sure there is lubricant in the gear case. Not overflowing but maybe 1/2 full when view with cover off on a level surface.

17. Apply some RTV sealant to trhe cover and install it. Tighten bolts evenly. Light torque (1-2 ft-lb).

18. Reassemble washing machine and test for leaks and proper operation.

2. Turn the water off.

3. Disconnect the supply and discharge hoses.

4. Open the cover and remove the cap/cover of the agitator. Use socket wrench to remove the bolt securing the agitator. Pull up on the agitator and remove it.

5. Lay washing machine down on it's front. Remove the inlet and outlet drain hoses from the discharge pump.

6. Remove the 2 "faston" connectors from the motor start capacitor (looks like a D cell flashlight battery). Rock the connectors back and forth and pull gently until they come off. Polarity doesn't matter but to be safe make note of the positions.

7. Press the release clip on the motor connector and pull to disconnect it. Move the wiring harness out of harms way.

8. Remove the 3 bolt securing the motor and transmission assembly to the bottom of the tub. Pull the drive assembly out of the machine and place it on a suitable work surface.

9. Examine the tub brake assembly (still on the bottom of the tub), the clutch assembly (on the motor/transmission assembly you just removed and everything else for wear or damage. Now if you decide to proceed with repair continue with the following steps. If not you're done.

10. Remove the inverted cup washer from the agitator shaft of the assembly. Remove the "U" clip from the shaft and remove the clutch mechanism from the drive assembly. Make a sketch of the position of each of the removed components to aid in reassembly.

11. Now you can see the gear case cover and it's seal. If it is leaking (as mine was) you will need to replace it.

12. With the assembly level remove the bolts around the cover and remove the cover. Place the cover on a flat surface and with a screwdriver or punch drive the old seal out of the cover from the outside in.

13. Clean the seal area and check for damage. Clean the cover and transmission housing surfaces of old gasket material. There is a factory sealant available for reassembly but I chose an automotive RTF @ $4 vs $24 and it worked OK.

14. Installing the seal requires some tools and experience to done successfully. The right size sockets or piece of pipe, coupled with an arbor press or vise will get the seal in. The cover is delicate so if in doubt find a machine shop.

15. Support the outside of the cover on a hard surface and with a socket or short pipe length, PRESS (don't hammer) the new seal into the gear case cover.

16. Make sure there is lubricant in the gear case. Not overflowing but maybe 1/2 full when view with cover off on a level surface.

17. Apply some RTV sealant to trhe cover and install it. Tighten bolts evenly. Light torque (1-2 ft-lb).

18. Reassemble washing machine and test for leaks and proper operation.

Parts Used:

-

Thomas from Pascoag, RI

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers, Socket set

20 of 22 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Idler Pulley broke

I disconnect the power, then the vent pipe. I removed the back panel of the dryer to access the pulley and removed the belt. Replaced the back and put everything back together.

Parts Used:

-

Keith from Richmond, VA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Socket set

21 of 26 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The spin gear was striped.

I had to take the motor and transmission out. They are one piece. Removed the clutch, take off trans. cover, remove a snap ring, take the striped gear off, and put the new one on. Then put put everything back on the way it came off.

Parts Used:

-

Aaron from Lake Mills, WI

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Socket set

21 of 27 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Although the motor was running, washer wouldn't agitate or spin.

After disconnecting the electrical supply, first remove the two screws at either end of the control panel and fold it back away from the washer top. Then, unplug the electrical lid switch connection. Now, remove the two clips at either end on top to disconnect the housing from the washer back and chassis. The motor is sandwiched between the water pump in the front and transmission at the rear. The Direct Drive Coupling connects the rear motor shaft to the transmisson. After you have taken the outter portion of the washer off, remove the two snap clips that hold the water pump in place and slide the pump off the front shaft. Best to also disconnect the upper hose connection so the pump can be moved out of the way. Caution though, remaining water in tub will drain out. Now remove the two screws that hold the clips in place which secure the motor to the transmission. Careful, as the old Direct Drive Coupling is probably destroyed, the clips are the only thing holding the motor in place and the motor needs to be supported so it won't drop to floor when the clips are removed. Be careful not to lose the four rubber grommets which sit between the motor and transmission bracket. After motor is on floor remove the old plastic slip-on direct drive coupling discs from both the motor and transmission shafts. The new replacement discs have steel centers which do not slide onto the shafts as easily as the old plastic ones did. I had to tap the center steel portion onto the shafts using a hammer and a deep wall socket the same width as the steel portion of the disc. Be careful! I'm sure that tapping the plastic portion of the disc to properly seat it on the shaft will break it away from the steel portion. In my case, It took me several attempts to completely seat the new discs. I had to do quite a bit of tapping to get the discs seated far enough onto the shafts so that the motor slipped easily against the transmission bracket grommets and the retainer clips snapped back into place easily. Reassembly is simply reversing the steps you took when taking the unit apart. Before putting the outter housing back in place, I checked to make sure everything was running smoothly by jumping out the electrical snap-in connection for the lid switch and running the machine in the spin cycle. Remember, if you don't jump out the lid switch and just try to test the unit in the aggitate cycle, the machine has to first fill with water.

Parts Used:

-

Thomas from Commack, NY

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers, Socket set, Wrench set

20 of 24 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer stops on 1st spin/drain cycle

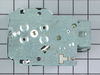

Unscrew timer/main control knob, then remove 2 spacers behind the knob. Remove 2 main control panel screws at each front lower corner. Rock panel back (pull slightly forward before rocking back to release plastic notches) to expose wire harness and timer. Remove 2 screws holding timer and disconnect timer electrical connector. Put new timer on with screws and attach connector correctly. Rock panel forward into place and reattach panel screws, spacers and knob. Note: Make sure lid switch is working properly before assuming the timer is bad. My switch is also intermittent and needed a shim on lid male plastic piece to engage the switch plate.

Parts Used:

-

Michael from Coeur d'Alene, ID

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

20 of 26 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

noisy drum

the job would have gone faster if the right parts had been sent in the first place. I would have never paid for two day shipping. In the repair, I removed the rear panel, clipped the plastic triangle holding the bearing, installed the new bearing and new clip.

Parts Used:

-

Jeff from Mesa, AZ

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers, Wrench (Adjustable), Wrench set

20 of 26 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Top Half of Agitator would not function without appying sideways pressure

Heard about the website... 1 minute to find it, 10 minutes to order new cogs... 3 day wait for new parts... Rec'd Fedex, 15 minutes total to pull the agitator cover (bleach dispenser) then the bung cover with o-ring (just lift out) expose bolt, unskrew and remove top portion of agitator or entire agitator if it's easier. Seperate, remove black cog holder (slides up the spindle) and replace cogs one at a time just like the old ones. Reassemble in reverse and you are back in business. Saved the $75 deductible on my home appliance warrenty. You guys are the best... cheers...

Parts Used:

-

Donald from Fredericksburg, VA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Socket set

18 of 21 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

idler pully sqwieling

once the back is off remove belt from tentioner and remove v clip. smooth shaft with wd-40 and scotch brite , then install new idler replace v clip

and your done !!!

and your done !!!

Parts Used:

-

Jerry Duty from Fort Walton Beach, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

19 of 24 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Agitator was barely agitating. Making a clicking noise.

Removed agitator cap. Removed bolt inside with socket wrench. Located plastic cogs Pulled out old cogs and slid in new cogs and put back together and works great. Easy to take apart and put back together. Very cheap repair. Cogs less that $4.00 plus shipping. Shipped next working day.

Parts Used:

-

Charmaine from Slidell, LA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Socket set

17 of 18 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Would not spin

Remove the nut from the top of the motor shift inside of wsher. then remove the wire harness plug. Take out three bolts side the shaft and motor out. Replace clutch and install in reverse order.

Parts Used:

-

floyd from Slidell, LA

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers, Socket set

23 of 39 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Leaking drain hose

First I removed hose from drain, next I loosened the clamp at the drain hose connection at the washer. Removed hose. Have rags/towels as there is some residual water that will spill out of the washer. Reinstall in reverse.

Parts Used:

-

Steve from Cypress, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers

16 of 19 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer drum was not turning when started.

I moved the dryer to a location where I could get to both the front and back sides. I opened the back by first removing the top cover and then the back. It requires either a Phillips head screwdriver or a quarter inch socket. In addition, it requires removing the four power wires which connect to the computer. If you are unfamiliar with the wiring layout, take a photo with your cell phone which you can then refer to when re-assembling. Once the back was removed, I saw that the belt was still intact, but the pulley which provides tension to the belt was frozen. Take a photo of the belt route between the motor and the pulley. Try to get the spring position in the photo. Remove the belt from the pulley by reducing the tension and then sliding the belt out (this assumes the belt is not broken). The pulley arm is held in place by a single bolt which can be removed by a socket set. Remove the arm with the pulley attached. Examine the pulley to figure out why it is frozen. In my case, the pulley had been frozen for some time and the belt had actually chewed through the pulley and was sliding (polishing) on the pulley axle? I used a pair of pliers to loosen the destroyed pulley by rotating it back and forth over the axle while gripping the arm the axle is attached to. As it loosened up I worked it off the axle. I used a cloth to clean the axle of grime from the belt, pulley, and dryer lint. The new pulley comes with a washer and triangular plastic "fastener". First you put on the washer, then the pulley and then you secure it on the axle by sliding the triangular fastener over the axle so it sits in a small grove near the end of the axle. Then put the pulley arm back by replacing the bolt. Make sure you do not overtighten the arm since it is intended to rotate about the bolt. If the dryer belt breaks, the spring will pull the arm down and throw a cutoff switch. Its operation should be obvious. Once the arm is back in place, refer to your photo and replace the spring (this can be tricky and frustrating, particularly if you don't use something like needle nose pliers). Once the spring is in place, depress it and re-install the dryer belt. Refer to the photo you took earlier if you've forgotten how the belt was routed. Then re-install the dryer's back panel, re-attach the electric wires (again refer to the photo you took earlier), and re-attach the top cover. You might want to test your handiwork at this point before you reconnect the dryer vent

Parts Used:

-

Dennis from AUSTIN, TX

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers, Socket set

15 of 16 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Door catch on dryer door broke

PartSelect sent me three different door catches with instructions for choosing the correct one. I did choose and simply inserted it into the slot and voile! All finished and it works great now! PartSelect had the part delivered the day after my order was placed. I would suggest doing business with them to anyone asking who they might contact for a part. I especially appreciated the ease of identifying and ordering from them. I was able to do all of this on-line via their website.

Parts Used:

-

Lynne from Jamestown, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

14 of 14 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer would not turn

My dryer starter squeaking in December 09 and the repairman told me that it would cost between $200-$500. I did not let him fix it as this machine is only 3 years old. When the part finally broke in April 10, I was ready to junk this and just buy a used dryer. My husband went on line and quickly figured out the part he would need to do the repairs. It cost under $20.00. Now my dryer is fixed and running and there are no squeaks. Thank you

Parts Used:

-

Kim K from Hurst, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Wrench (Adjustable)

15 of 18 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washmachine wouldn't spindry

I removed three bolts from the transmission and two clips that hold the motor to the drive gear. I replaced the brake cam that had cracked and the lining. Now it works great ! Ordered part on Friday before two and it came Saturday at four.

Parts Used:

-

Chuck from South Holland, IL

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers, Socket set, Wrench set

14 of 16 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!