SWSG1031HS2 Westinghouse Washer Dryer Combo - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

old belt

Took off the front panel and changed the belt. Putting on the front panel took longer then changing the belt.

Parts Used:

-

Joseph from Landing, NJ

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

Was this instruction helpful to you?

Thank you for voting!

Loud rattling and clanging noise

Remove front panel, controls and the whole front of the dryer. Split blower housing and remove blower fan. Slide new fan on shaft with flat side aligned and make sure tabs on the fan go into the groove on the shaft. Install clamp, and reassemble blower housing. Test operation by spinning dryer drum.

Parts Used:

-

carl from san luis obispo, CA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

Was this instruction helpful to you?

Thank you for voting!

Dryer was making a noise like scraching a black board.

The repair went very well.The biggest problem was the spring on the tension roller when putting back together.But it just takes a little bit of patients and it was fine.Works great now.

Parts Used:

-

Randy from New London, NC

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers

Was this instruction helpful to you?

Thank you for voting!

bad drive belt

-

rickey from nashville, TN

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

Was this instruction helpful to you?

Thank you for voting!

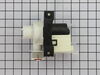

Not Draing Water

-

Sammy from Notasulga, AL

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

Was this instruction helpful to you?

Thank you for voting!

Dryer over heated tripped thermal limiter

Took apart dryer and replaced limiter located on back, reassembled dryer and tested wiithout connecting to vent. Dryer working fine without vent connection. However as always something simple turns to disaster when children help. While cleaning out lint from dryer vent which I will say was the original problem causing the limiter to trip, youngest son wanted to help. Son did not know that to walk in an attic you must step on joists not drywall. No one was hurt just banged up falling into the garage. Extended repair to ceiling added dificulty factor of 2 days and a bit of insulation clean up. Good news is the dryer works fine and the vent is no longer clogged up with lint. Watch your help it always adds to the repair.

Parts Used:

-

Kenneth from Carmel, IN

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

Was this instruction helpful to you?

Thank you for voting!

noise

-

Daniel from San Marcos, CA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

Was this instruction helpful to you?

Thank you for voting!

I had no problem

I used a flat-head screw driver to lift the main lid up off the washer to get to the washer lid safety switch..Unplug the plug from the electrical outlet. Removed the 4 wires from the switch, and removed 2 screws to remove the old switch..Then install the new safety switch in reverse order.

Parts Used:

-

Albert J. from Homosassa, FL

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

Was this instruction helpful to you?

Thank you for voting!

Symptoms suggested drum support bearing was problem.

Referred to Video and replaced drum support bearing as shown. Did not solve the problem as noise was still present. Called professional repairman, who replaced the belt pulley, along with all the parts I had just installed (came as part of a total kit). I was on the correct path, but just didn't go far enough to check out the belt pulley. If it should happen again, I could complete the whole repair process. Great learning process!!

Parts Used:

-

Calvin from Las Vegas, NV

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Wrench set

Was this instruction helpful to you?

Thank you for voting!

dryer stoped working

opened top of dryer, remove blown part and installed new part very easy.

Parts Used:

-

Larry from Jewett city, CT

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers, Screw drivers

Was this instruction helpful to you?

Thank you for voting!

began as intermittent squeal then became more louder and frequent

removed top-removed front-removed belt-removed drum (I didn't know how the drum came out WITH the bearing so I unscrewed the 3 middle screws on the back of the drum which released it from the bearing)- removed the bearing-that was when I knew what to order. installed the bearing on the drum before assembling all in reverse order. I wasn't sure how much grease to use so I used about 1/3 of it.

Parts Used:

-

Terry from Hermitage, TN

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set

Was this instruction helpful to you?

Thank you for voting!

Washer pump out

Was so easy the video link made it even easier. Will with no doubt return for any other problems for my appliances if needed.

Parts Used:

-

Dorothy from San Antonio, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers, Screw drivers

Was this instruction helpful to you?

Thank you for voting!

Water overflowed not shutting off.

I turned off water valves. I then unplugged the AC. I took the 4 screws out on the back end of the top cover of the washer. I removed the two water lines from the water inlet vales and the two electrical connectors. I then removed the two screws holding the water valve assembly and it came out easy. Installed new water valve assembly mounted with two screws , then put the electrical connection and water lines back on new water valve assembly. I turned the incoming water vales on and installed the top cover with the four back screws and was done.

Parts Used:

-

Harold from Portland, OR

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers, Screw drivers

Was this instruction helpful to you?

Thank you for voting!

My washer started making a loud, screeching noise and then stopped working.

Following the easy instructions on PartSelect's website, I first removed the screws from the bottom, front of the washer. Then, using the putty knife, I unhooked the clips holding the washer top to the front and pulled off the front. I pushed in the belt wheel and removed the old belt, which was being held on by one strand. Then, I put on the new belt, put the front back on, replaced the screws and then pushed the washer lid back down over the clips. It worked perfectly and took less than 15 minutes and cost me next to nothing. Thanks for a great site!

Parts Used:

-

Tom from Hamilton, OH

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

Was this instruction helpful to you?

Thank you for voting!

Dryer did not stay hot through complete cycle

This repair took about fifteen minutes. I popped the top of the dryer using a flat-blade screwdriver, leaned it back against the back wall, unscrewed two screws holding the front panel, removed the five electrical spade contacts after marking which went where, swung out the panel and lifted it off. After that, it was a simple job to unscrew the plate holding the solenoids in, at the bottom left of the unit. I replaced the solenoids, closed everything up and now the dryer is working better than it has in the last three years, or so. If your dryer is heating sporadically, the odds are 85%, or more, that a solenoid swap-out will correct the problem.

Parts Used:

-

Miles from Austin, TX

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Socket set

Was this instruction helpful to you?

Thank you for voting!