NVL333EB0CC Hotpoint Dryer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Loud squeal when dryer in operation

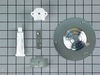

This was done to a washer/dryer that is in a closet and was worked on in place and not removed so it was all done through the front. Its a good idea to vacuum the inside out before putting it all back together. 1.Remove all of the screws that hold down the top of the dryer and remove top. 2. Remove the front slanted panel below the controls then Remove the two small black screws holding the plastic inserts on the left and right sides of the controls panel plus the two silver screws that will allow it to drop so that you can access the tabs that hold the front section on. 3. Remove screws holding the front section with the door on. The last two will be tabs at bottom that were hidden by control panel. Unplug connector and remove front. 4. Note how belt is positioned around motor and tensioner before removing belt.(just push tensioner until belt is loose enough to slide off of drum to remove belt). 5.Slide out drum and remove old bearing and replace with new one. Be especially careful tightening the three screws that attach the bearing as they are easy to strip. 6. To remove the bushing at the back of the dryer you will remove the two screws. but you will need to hold the clip on the back of the dryer or it will drop when the screws are removed. When re-installing MAKE SURE not to lose your ball bearing that the drum bearing will rest against. I used a strong small magnet to hold the ball bearing against the back of the nylon cradle bushing so I wouldn't lose it when re-installing the bushing and it worked great. Once the nylon bushing was back in place I lubed it thoroughly and put everything back in reverse order. I usually would not fill out one of these do-it-yourself forms but the instructions that are already listed with this part are completely different from what I encountered up to the actual bearing and bushing replacement. Hope this helps.

Parts Used:

-

Tracy from Washington, DC

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers

1 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Back Drum Bearing Worn Out

It took about 20 minutes, first I popped the top off using a flat screwdriver in my leatherman and removed the wires on the door switch then two screws holding the front on, and then I removed the drum which took a little longer because the belt tensioner was difficult to release because of limited space. Removed old bearing (ball and socket) and replaced with new one. I then reassembled in reverse order. Working great. . .

Parts Used:

-

Gene from LaGrange, GA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver

3 of 8 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Drum Guide And Seal Wore Out

Lifted top and removed front panel and cleaned old glue off. Put new glue on put seal used spring loaded cloth pins to hold till glue dried

Parts Used:

-

GARY from SPRING VALLEY, MN

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers

1 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Terrible squeaking sound

Squeaking was coming from the back of the drum, not the glides. The hardest part was trying to figure out how to pull the drum out. With a little extra tug, the back pin of the drum lifted out of the socket. That was the cause of the sqeak. Just cleaned it up and added some grease and good as new. I noticed the front glides were worn and replaced it.

Parts Used:

-

Michael from Shrewsbury, MA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

1 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Start knob was broken off flush with switch

I turned off the power, unscrewed the 4 screws from the top of the dryer. I then opened it and turned the switch that was in there counterclockwise exactly as utube video said to do. I then took off the two wires from the old switch. The rotary start switch fix right in where the old one was. I put the panel back together, put on the old knob and turned the power back on! It took less than 15 minutes from start to finish! If I can do it anyone can! Joanne Klinkhammer Cecil, Wisconsin

Parts Used:

-

Joanne from Cecil, WI

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

1 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Timers are made to turn clockwise and break when turned counter clockwise

We are a retirement community and when we opened March '07 the company purchased GE washer and dryers to go in our common area laundry rooms for the residents to use. Because of their age, they will often turn the knob counter clockwise and not the right diirection which breaks the device which is not good. With in 3 days of installation they had broken 2 of the new knobs.

But, the ordering was simple, the shipment was fast and the install was quick for the maintenance tech.

But, the ordering was simple, the shipment was fast and the install was quick for the maintenance tech.

Parts Used:

-

Dwayne from lawrenceville, GA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Pliers, Screw drivers

0 of 1 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

backet seteled and belt spined arround without going traction

-

Yuriy from West Springfield, MA

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

0 of 1 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer sounded like a stuck pig

I ordered the rear bearing kit from the local supplier here in Marsh Harbour, Abaco the Bahamas. Delivery for the kit was 3 to 4 weeks from my local supplier.NOT PARTSELECT.

While waiting I found this site and after reading the VERY helpful instructions from your customers, I realised that I would probably need additional parts, top and bottom front felt seals, maybe a new drive belt.

I ordered these online and had the parts deliverd to a friends address in West Palm Beach Florida. The parts arrived in about 2 days. My wife was already there and brought the parts back.

Installation was very straight forward. Read the other installation reports and you will not have a problem.

The only thing I can add is, DO NOT LOOSE THE SMALL BALL BEARING. I did and it took me about an hour to find it.

My suggestion is to do a dry run installation of the bracket WITH OUT the small ball bearing. Tape the backing plate?that keeps the ball breaing inplace to the outside of the back panel with duct tape so that the screw hole will line up. Once this is done put some grease (Supplied with the kit) in the hole on the nylon bracket and attach with the two screws, do not over tighten. Grease up the area where the rear bearing shaft support will sit.

Installation of the rear bearing shaft support was straight forward. This is on the dryer drum. Extra hands are must for this.

I was very pleased with Partselct.

Dryer works like new.

While waiting I found this site and after reading the VERY helpful instructions from your customers, I realised that I would probably need additional parts, top and bottom front felt seals, maybe a new drive belt.

I ordered these online and had the parts deliverd to a friends address in West Palm Beach Florida. The parts arrived in about 2 days. My wife was already there and brought the parts back.

Installation was very straight forward. Read the other installation reports and you will not have a problem.

The only thing I can add is, DO NOT LOOSE THE SMALL BALL BEARING. I did and it took me about an hour to find it.

My suggestion is to do a dry run installation of the bracket WITH OUT the small ball bearing. Tape the backing plate?that keeps the ball breaing inplace to the outside of the back panel with duct tape so that the screw hole will line up. Once this is done put some grease (Supplied with the kit) in the hole on the nylon bracket and attach with the two screws, do not over tighten. Grease up the area where the rear bearing shaft support will sit.

Installation of the rear bearing shaft support was straight forward. This is on the dryer drum. Extra hands are must for this.

I was very pleased with Partselct.

Dryer works like new.

Parts Used:

-

Christopher from Palm Beach Gardens, FL

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers

3 of 10 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

broken spindle which required a total switch replacement.

It took longer to vaccume the lint out of the machine than to change the part.

The part replacement is done without any tools.

My wife could have done it

The part replacement is done without any tools.

My wife could have done it

Parts Used:

-

Jonathan from Ridgefield, CT

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

0 of 1 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Start switch broke off

I followed the video instructions. I did have to run to the hardware store to pick up a torx screwdriver but otherwise the instructions were perfect. I generally hire someone to do repairs, but this was too easy! I highly recommend doing this yourself as it is definitely a time and money saver. The website made ordering easy and the part arrived quickly!

Parts Used:

-

Pamela from Atlanta, GA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

0 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer making squeeky noise.

-

NICOLAS from LYNN, MA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Wrench set

1 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The switch was broken and had to use pliers to start dryer

Disconnected the power removed 4 screws from top panel. Removed 2 wires, turned switch counter clockwise. remopved switch. Replaced with new switch,connected the 2 wires, put panel back inplace,put screws back in panel,plugged dryer back in. SUPER SIMPLE Total time 5 minutes

Parts Used:

-

Dan from Fernley, NV

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers, Screw drivers

Was this instruction helpful to you?

Thank you for voting!

noisy belt

Removed top of dryer, took screws out of back of dryer, pulled drum off front of dryer, removed old belt and slid new one in place. Reattached drum to front and slid belt in place only to find it was the wrong size. Called an appliance repair man, he said happens more ften than not.

Parts Used:

-

Randy from Lake Mary, FL

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

Was this instruction helpful to you?

Thank you for voting!

Sticker Switch Worn Out

-

Roy from Sun City West, AZ

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

Was this instruction helpful to you?

Thank you for voting!

Lack of grease caused bearing to go out

I took the top and front off the dryer. I then took the screws out of the drum and removed the drum. I then took the old bearing out and put the new one in.

Parts Used:

-

GARY from HALEYVILLE, AL

-

Difficulty Level:Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers, Wrench (Adjustable)

Was this instruction helpful to you?

Thank you for voting!