LDGA200AAE Admiral Dryer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Dryer made noises like metal on metal grinding

Unplugged the dryer then popped the top off and tilted it back, exposing the drum. Then using a flat bladed screw driver, removed the two sheet metal screws holding the front panel on. Once the front panel was removed, I pulled the drum off, exposing the motor and worn pulley. I removed the pulley arm, then removed the pulley. The bearings were totally gone, so I replaced it with a new pulley, replaced the belt and the front drum glides, since they were obviously worn. While it was apart, I cleaned out the interior with a shop vac, which greatly improved the efficiency of the dryer.

Parts Used:

-

Greg from Salt Lake City, UT

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

7 of 8 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

No Heat After 10 Minutes

Shut off gas removed gas valve. Removed the coil retainer and installed the new coils. Reinstalled valve and checked. Found dryer worked fine.

Parts Used:

-

lawrence from GROTON, VT

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Wrench set

7 of 8 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Rattling sound at front of the dryer and noticable longer time to dry clothes

The hardest part of my repair was to move all the stuff (sh**) that had accumulated around the machine. We have had our Maytag dryer for 10+ years and a lot of things have been stacked or piled near it. Once the dryer was pulled out and the top could open, it was a matter of disconnecting the door light switch (just remove from clamp and pull out of the way),15 screws, 1 snap ring and a spring clamp. removal was simple, however installation was slightly harder because the new blower wheel's opening for the motors arbor was very tight. I had to use a hammer to drive it on the arbor, no hard hits but to hard to slip on. then another 10 mins to vaccum out all the lint. all together from start to finish was about 40 mins. If you have done any home repairs this job will be simple, hope this helps

Parts Used:

-

Michael from Stockton, CA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers

7 of 8 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

old latch broke

-

Jim from Germantown, WI

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

8 of 11 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

the glow ignitor would not cycle on

I had an issue where I was not getting any power to my ignitor. After replacing the ignitor with a fresh one, the problem persisted. Next, I went hunting all the fuses and therrmostats for continuity. All seemed fine. So finally I decided to jump the flame sensor which is located on the outside of the flame tube. WHALLA! It ignited the glow plug. So with one 1/4"" nut driver I removed the single bolt from the unit, then I used a pliers to remove the two wires from the old unit. I replaced the sensor with Tue new unit and all was well. It took less than 5 min once I diagnosed the problem.

Parts Used:

-

Georgio from Oradell, NJ

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver, Pliers

7 of 8 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer would not dry igniter went bad

Easy Job.

First take a flat head screw driver and pop the top placing the screwdriver in between the front panel. The top of the dryer should pop up.

Then just pull it up and over towards the back.

Then unscrew the front panel and move it out of the way leaveing the front door atached to the panel.

Once you open the front panel' You can pull the dryer tub out by sliding it out and at the same time you need to push the belt towards the back of the tub until it comes off.

Now you can get to the ingiter by first disamablethe gas

housing first.

Simply by taking one screw off and disconnecting the gas line fitting in front of the dryer. Also disconnect the 3 sets of wires that are connected to that piece and the igniter.

The hole piece will then come out with the igniter attached to it.

Next disconnect the igniter from the piece and replace it with new one.

Then put back togather the same way you took it apart.

Reinstalling the tub.

When it's time to put the tub back in; there's a trick to that.

Put tub in about 3/4 of the way in, put the belt around the tub and let the rest hang to the floor inside dryer.then crawl into the tub and stetch your head and arm through the tub on the back side.

Then you can get to the belt and route it into the motor and the pully that is spring loaded it makes it so much easer that way then trying to run the belt and route it in place from the top. Once that is done now you can adjust belt back to its orignal position then push the tub back in place. Reinstall fron panel and your their.

Total cost 36.00 plus shipping. Thats a lot cheaper then a sevice call and labor

First take a flat head screw driver and pop the top placing the screwdriver in between the front panel. The top of the dryer should pop up.

Then just pull it up and over towards the back.

Then unscrew the front panel and move it out of the way leaveing the front door atached to the panel.

Once you open the front panel' You can pull the dryer tub out by sliding it out and at the same time you need to push the belt towards the back of the tub until it comes off.

Now you can get to the ingiter by first disamablethe gas

housing first.

Simply by taking one screw off and disconnecting the gas line fitting in front of the dryer. Also disconnect the 3 sets of wires that are connected to that piece and the igniter.

The hole piece will then come out with the igniter attached to it.

Next disconnect the igniter from the piece and replace it with new one.

Then put back togather the same way you took it apart.

Reinstalling the tub.

When it's time to put the tub back in; there's a trick to that.

Put tub in about 3/4 of the way in, put the belt around the tub and let the rest hang to the floor inside dryer.then crawl into the tub and stetch your head and arm through the tub on the back side.

Then you can get to the belt and route it into the motor and the pully that is spring loaded it makes it so much easer that way then trying to run the belt and route it in place from the top. Once that is done now you can adjust belt back to its orignal position then push the tub back in place. Reinstall fron panel and your their.

Total cost 36.00 plus shipping. Thats a lot cheaper then a sevice call and labor

Parts Used:

-

mike from lemont, IL

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers, Wrench (Adjustable)

9 of 14 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

no heat was being produced

Remove back panel n u can see the sensor and easy to replace thanks to the print out i was provided love this website

Parts Used:

-

reinaldo from guttenberg, NJ

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

9 of 14 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer would not come on

Verified power to the dryer with a volt meter. Identified the high limit fuses under the top cover. I used an ohm meter to determine the fuse located on the heater housing assembly was bad. The fuse located at the top (blue label) was not bad but I changed it since a new one was sent in the kit. Reassembled the dryer and it has been working ever since. Found the problem on a Monday and ordered the part. Received the part on Wednesday and the problem was solved. Cost me about $31. Would have been triple that if a repairman would have been called. Thanks PartsSelect

Parts Used:

-

Max from Wylie, TX

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

6 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

No Power

(Electric) I opened the lid and propped it back on wall. The first piece was located all the way in the back mounted toward you. Easy enough. When it came to the thermal fuse, it was a bit trickier. It's located on the right side of the heating element wall. There is a screw straight on top of the wall. Mine was covered in lint, hence the thermal repair work:) Take the screw all the way out. The fuse is removed by lifting out the thermal fuse mounting bracket. Nothing special holding it in place. Just put the new one in the same way the old one came out. It was a bit difficult to wiggle the bracket back in, but I kept playing enough and it finally lost the battle. Put the screw back in, taking care to make sure it threads on top of the bracket to secure it against the heater element wall. Worked for me! Thanks everyone.

Parts Used:

-

James from Berlin Hts., OH

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers

7 of 9 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

fusible link repeatedly opened

I applied the excellent description of accessing and fixing the drier givenby others. When the second fusible link opened, I consulted the Repair Forum. Denman, an obviously experienced responder, walked me through the diagnostics.

I did not ask denman's permission to pass on his recommendations so they may or may not apply to your situation. Heere

"Here are your parts with a wiring diagram

Maytag YE225LV

With the unit apart and drum/belt removed and thermal fuse wires shorted together the motor should run. You also have to tape or hold the door switch closed. I would also disconnect and tape up one of the wires going to the heater coil as it will overheat. Never leave the thermal fuse shorted as the unit can cause a house fire without it.

Be very careful that everything is well taped up so you do not get a short.

You have 220 volts in the unit which is very dangerous.

The motor should manually turn easily from the pulley end.

The ding from the fan indicates that there is a problem here. Check it carefully.

Here is a good site

Dryer Help Sections, repairing dryers, Kenmore, Whirlpool, Maytag, Inglis, GE, Frigidaire, White Westinghouse, Magic Chef, Norge, changing a 3 prong cord to a 4 prong cord, no heat, electric dryers, gas dryers, how to take apart my dryer, what can st

Check out the Maytag Dependable Care section / 26 -motor problems / "Check this out" at the bottom of the page

Normally your high limit safety thermostat should open before the thermal fuse blows.

When you ran your test did you run it on fluff (no heat) at first?

I would remove and check the heater for a grounded element.

Depending where it breaks/shorts it can be on high heat all the time with the thermostats having no control of it.

From your description this would be my prime suspect!!"

My observations:

1 the reference above is to applianceaid.com, which had useful tips. Tip #4 was washing the filter screen with detergent, as it holds an invisible layer of residual lint.

3. When cleaning, disconnect front panel, take out filter and clean the cavity behind the filter. I used a garden hose and large volumes of lint came out.

Now I am scheduling full clean out at least annually, including washing screen and inside door.

2. since thermal fuses are designed to open when overheated, it is hard to test if they work or not. (They test continuous at room temperature.)

3. at Denman's subsequent suggestion, I replaced the thermal fuse past the blower. (There is a thermal fuse ahead of the heating elements and the elements heated, so it is a less logical failure candidate.)

System working fine. The help was worth as much as the parts!

I did not ask denman's permission to pass on his recommendations so they may or may not apply to your situation. Heere

"Here are your parts with a wiring diagram

Maytag YE225LV

With the unit apart and drum/belt removed and thermal fuse wires shorted together the motor should run. You also have to tape or hold the door switch closed. I would also disconnect and tape up one of the wires going to the heater coil as it will overheat. Never leave the thermal fuse shorted as the unit can cause a house fire without it.

Be very careful that everything is well taped up so you do not get a short.

You have 220 volts in the unit which is very dangerous.

The motor should manually turn easily from the pulley end.

The ding from the fan indicates that there is a problem here. Check it carefully.

Here is a good site

Dryer Help Sections, repairing dryers, Kenmore, Whirlpool, Maytag, Inglis, GE, Frigidaire, White Westinghouse, Magic Chef, Norge, changing a 3 prong cord to a 4 prong cord, no heat, electric dryers, gas dryers, how to take apart my dryer, what can st

Check out the Maytag Dependable Care section / 26 -motor problems / "Check this out" at the bottom of the page

Normally your high limit safety thermostat should open before the thermal fuse blows.

When you ran your test did you run it on fluff (no heat) at first?

I would remove and check the heater for a grounded element.

Depending where it breaks/shorts it can be on high heat all the time with the thermostats having no control of it.

From your description this would be my prime suspect!!"

My observations:

1 the reference above is to applianceaid.com, which had useful tips. Tip #4 was washing the filter screen with detergent, as it holds an invisible layer of residual lint.

3. When cleaning, disconnect front panel, take out filter and clean the cavity behind the filter. I used a garden hose and large volumes of lint came out.

Now I am scheduling full clean out at least annually, including washing screen and inside door.

2. since thermal fuses are designed to open when overheated, it is hard to test if they work or not. (They test continuous at room temperature.)

3. at Denman's subsequent suggestion, I replaced the thermal fuse past the blower. (There is a thermal fuse ahead of the heating elements and the elements heated, so it is a less logical failure candidate.)

System working fine. The help was worth as much as the parts!

Parts Used:

-

Stephen from Wayme, NJ

-

Difficulty Level:Easy

-

Total Repair Time:More than 2 hours

-

Tools:Screw drivers, Socket set

7 of 9 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Part cracked and clothes were getting caught

First I removed the screws that held the part in place, but this proved to be the hardest part for me. I had to find the right kind of screw driver . It was not a slotted or Phillips. It was more star shaped. Once I had the right tool, the rest was pretty easy.

I then opened the top of the dryer to be able to lay the front on the floor. There were wires connected to the front, however, so I had to remove the part that the wires were connected to by slipping it out of the bracket that held it in place. Once the front panel was on the floor, I simply lifted the old part out and placed the new part in. I closed the front, replacing the part with wires back into the bracket, locked the top down tight, replaced the screws, and I was finished.

I then opened the top of the dryer to be able to lay the front on the floor. There were wires connected to the front, however, so I had to remove the part that the wires were connected to by slipping it out of the bracket that held it in place. Once the front panel was on the floor, I simply lifted the old part out and placed the new part in. I closed the front, replacing the part with wires back into the bracket, locked the top down tight, replaced the screws, and I was finished.

Parts Used:

-

Cathy from Dallastown, PA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

6 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

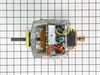

Dryer Quit running

First off I want to say I ordered my motor on Sunday night at 11:30 PM on veterans day and got the two day delivery. My part was sent out on that Monday (fed. holiday) and I received it Tuesday around 1:00 pm after I disconnected the wiring harness, took the blower fan C-clips off, unscrewed about 6 screws, and pulled the assembly apart I just done everything in reverse and replaced the new motor. I discovered that my thermostat fuse was blown so I ordered the High temp thermostat kit from here (two day delivery) on Wednesday at 10:30 PM and got the parts Friday at around 2:00 PM. After taking out four screws and four wires I replaced the fuse and high temp. set, pushed the start button to see if it worked and it started up like new. Now it heats twice as fast and everything doesn't have a light burnt smell. So dry time is faster (no more 80-90 min. cycle times), less dryer sheets (to cover smell) and all this added up to cost savings on electric bill and dryer sheets. It took a week to get my dryer back (because I just looked at the motor) but in the end I needed the fuse and motor. The quick turn around time to get the parts, the pictures to see if I had the right parts, and the ease of ordering the parts meant only one run to the laundry mat, and that wouldn't have happen if the dryer hadn't messed up on laundry day.

Parts Used:

-

William from Marion, VA

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

6 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

blower wheel broken

unplugged the dryer.

opened it up.

unscrewed the housing that was holding the blower wheel.

removed the broken blower wheel.

placed the blower wheel on the shaft.

got a socket wrench and an extender to tap the blower wheel into place. I put a towel over the socket wrench so as to be gentle on the blower wheel. I tapped it down until I could fee the grove on the shaft where the washer used to go to hold in the old blower wheel (the new one has enough grip on its own to stay put).

put the housing back on after doing a few spin tests to make sure the blower wheel was spinning freely.

did some spin tests after putting the housing back on.

reassembled the dryer, plugged it in.

turned it on to test again.

done.

opened it up.

unscrewed the housing that was holding the blower wheel.

removed the broken blower wheel.

placed the blower wheel on the shaft.

got a socket wrench and an extender to tap the blower wheel into place. I put a towel over the socket wrench so as to be gentle on the blower wheel. I tapped it down until I could fee the grove on the shaft where the washer used to go to hold in the old blower wheel (the new one has enough grip on its own to stay put).

put the housing back on after doing a few spin tests to make sure the blower wheel was spinning freely.

did some spin tests after putting the housing back on.

reassembled the dryer, plugged it in.

turned it on to test again.

done.

Parts Used:

-

Aaron from Santa Rosa, AL

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Socket set

6 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer got hot then heat would shut off

Sensor is in the front lower left. Gas off, electicity off. Removed two screws for the filter, pry/lifted the top up and taped it too the overhead cabinet, removed two screws inside top of front panel, lifted pandel with door closed staight off. Two screws to remove the flame sensor braket. unplug the old sensor install the new one and reverse everything. With others suggestions I purchased temperature switches etc. but the radiant flame sensor was the problem. I now have some spare switches for future. Excellent company and very quick service. Oh, Sears wanted 200.00 just for the service call, I live rural.

Parts Used:

-

Douglas from Fernley, NV

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Socket set

6 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Broken Lint Duct tearing clothes and collecting large amounts of lint

After reading the comments of on-line customers, I realized the dryer opens like the hood of a car and then you pull the front of the dryer door off in order to get to the two screws holding the old lint duct housing unit. Putting the new part on was easier, but I would have appreciated a detailed picture along with the written instructions. Thank you for your quick delivery. Kathleen Yosso

Parts Used:

-

Kathleen from Belmont, CA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

7 of 10 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!