KUDS02FRSS1 KitchenAid Dishwasher - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Broken Door Links

Remove two screws at top that fasten dishwasher to cabinet. Slide dishwasher out to expose the two links that attach the door to the springs. Fit the new links to the springs and door.

Parts Used:

-

Randall from Moreno Valley, CA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

15 of 16 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Stopped cleaning dishes

First i remove upper rack held in by 2 clips at end of metal tracks. Compress inside clips and pull up then slide rack out of tracks.Then remove bottom rack just pick it up.Then i removed bottom sprayer by unscrewing center thumb screw. Then removed feeder tube for top sprayer held in place by 2 ea. phillips screws one on celin of tub and one at back of tub. Move tube to the right which unlocks it and remove. This has to be done to expose 4 ea. star screws. Remove screws and pop screen cover off. You have to take a towel and soak up water to expose bottom of inlets and outlets for water. You will then see the chopper blade with metal screen behind it. It is held in place with on star screw to the left of round top cover. Remove cover and pull on chopper blade which will release it from fingers mated from shaft to chopper blade .While pulling on chopper blade toward front of dishwasher pull up on metal screen it will come out. Clean all food particals out i used a shop vac worked well. Be careful not to drop screws in water inlets. The plastic shaft was broken in half by a piece of dental floss wrapped around shaft. I hope this helps it was not that diffacult just hard to work over door.

Parts Used:

-

Steve from Lexington, SC

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

15 of 16 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Seal on dishwasher worn out and coming loose.

Removed old seal, cleaned track, applied adhesive for new seal, seated new seal in track, closed door for 24 hours to allow adhesive to cure, then used dishwasher without difficulty. An easy repair.

Parts Used:

-

william from Wethersfield, CT

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

15 of 17 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

broken fill valve

that there is 90% of the repair made easy when you have the correct part. there is no better then direct replacement parts. the repair was self explanitory. one screw, two lines, lock in place, done. thanks for having the correct parts,that is what makes a job simple.

Parts Used:

-

John from Capac, MI

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Pliers, Wrench set

15 of 17 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Water leak

I watched the instructional videos that showed how to replace the inlet fill hose/water inlet a couple of times. The repair was exactly as shown. No trouble at all.

Parts Used:

-

J from HARPERSVILLE, AL

-

Difficulty Level:Very Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers, Wrench (Adjustable)

16 of 20 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Pump/motor assembly make making loud noise & door balance cable broken

I removed the dishwasher from under the cabinet. This is what took the most time. Before removing the dishwasher from under the cabinet I disconnected the drain cable to remove all the water from unit. After removing the dishwasher I tipped the unit on its left side. The motor/pump assembly is held in with one screw. After removing this screw the pump/motor assembly comes out with a 1/8 turn counter clock wise. The replacement pump/motor assembly was put back in in reverse order. After the pump/motor assembly was replaced I replaced the door balance cable kit on the right side of the unit. Next I tipped the unit on to its right side and replace the left balance cable kit. After this all that was left was to return the unit back under the cabinet and hook up the water supply line, the drain line, and the power.

Parts Used:

-

David from Bartlett, IL

-

Difficulty Level:Really Easy

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers, Socket set, Wrench set

14 of 15 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dishwasher door falls down as soon as it is unlatched and moved just a few inches open

This kit comes with the link cords and the balance wheels. I only needed the cords. I undid the set screws under the counter edge and slid the Dishwasher out from under the counter. One of the links had a broken cord and the spring had snapped to the very back of the space and was a bit hard to find. I used the good side as a guide to see how to thread the cord correctly. I did not replace the wheels since they appeared to be in good shape and looked like they might be a bit more difficult to replace than just the cord. For a second I thought I had ordered the wrong part because the new cord's attachment point at the hinge did not look exactly like the originals but the new design worked just like the original. I did need one other person to help stretch the spring and hold the door in the best position so I could attach the cord to the hinge. It's working perfectly now and I saved the wheels in case I need them later.

Parts Used:

-

Joellen from Castro Valley, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

12 of 12 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Door Pops open when running

I changed the Springs,Cables,Hinges (both) also changed both latches one on the door and the striker on the top of the tub. Problem still exists. Call worldpool today they never heard of this issue but if you google kitchenaid Dishwasher door pops open you get all kinds of hits.. You guys were great no problem with the parts..

Parts Used:

-

Robert from Coral Springs, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set, Wrench set

15 of 21 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Unit started only intermittently and then finally fail to start at all.

Unplugged unit from power source.Removed the screws fastening the interior panel to the door. Removed latch assembly from the door after disconnecting two wires to the microswitch. Removed microswitch from the latch assembly, then installed same microswitch in new latch assembly. Re-connected wires and re-installed latch assembly. Re-installed interior panel with screws. Re-connected unit to power source. Tested unit. Has started reliably ever since.

Parts Used:

-

Joseph from Gilroy, CA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

13 of 15 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

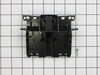

No lights on control panel

-

Alex from Costa Mesa, CA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

13 of 16 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Upper Spinner in Dishwasher

The upper spinner was laying in the top washer basket. I went online but no help was avaiable. Went to store where we purchased dishwasher and they gave me part number to order but not online I had to call to order. Part arrived in about three days. I took two screws loose on the top of dishwasher removed broke retainer to put new retainer in but I drop it into dishwasher so you have to me very careful

so I tried to order just the retainer but is not sold by it self. Had to order whole new kit. Other than that it is easy dishwasher runs like a new one.

so I tried to order just the retainer but is not sold by it self. Had to order whole new kit. Other than that it is easy dishwasher runs like a new one.

Parts Used:

-

Larry from Abington, MD

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

12 of 13 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

cap fell close to the heating element and was damaged and needed to be replaced

-

ronald from los angeles, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

13 of 16 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Door was falling open uncontrollably

First, ordering parts and getting diagrams from parts select is so efficient and make tthe installation so manageable. Using installation tips off the site gives u confidence to do it.

My issue was that I could not get the dishwasher from under the counter.

I removed the kick plate and screws holding it to the counter, but it was not coming out all the way. So I had to use a coat hanger to hook the spring. I attached the nylon cord first. Then I pulled the spring taut with the hanger and it was easy to thread the cord around the pulley system. I actually attached it to the door before tensioning the spring to make it easier.

Door works great now.

My issue was that I could not get the dishwasher from under the counter.

I removed the kick plate and screws holding it to the counter, but it was not coming out all the way. So I had to use a coat hanger to hook the spring. I attached the nylon cord first. Then I pulled the spring taut with the hanger and it was easy to thread the cord around the pulley system. I actually attached it to the door before tensioning the spring to make it easier.

Door works great now.

Parts Used:

-

Peter from Westfield, NJ

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

12 of 13 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Soap Door Latch Pin Broken

Needed to replace whole soap dispenser unit. Had to take front door apart cause the hex screws are on the inside. (10 Screws) then doors falls off onto floor if not careful. Spring loaded inner door wants to go up and outside door wants to fall off pulling on wiring. Unplug wiring to solinoid,(plug has locking release lever that needs to be pulled on) remove 6 hex screws, and dispenser comes out. Install new unit with 6 screws, plug in, and get help holding door parts together while installing the 10 screws. You are now finished. Pros are you get the complete unit, and not a bunch of parts. Cons are no diagrams or instructions/no new 6 hex head screws-reuse old ones. . . . . . Do not use soap powder/causes damage to latch parts/use only liquid soaps. . .

Parts Used:

-

daniel from corte madera, CA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers

13 of 16 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

No Power

The first thing I did to repair my diswasher was call a repair company. They wanted $175.00 just to look at it, so I scheduled an appointment. Then, I did an internet search for dishwasher repair. I learned about bi-metal fuses, and how to check them. I found my bi-metal fuse was bad, so I ordered a new one through parts select. My part arrived in two days. I installed it easily, and the dishwasher worked. Finally, I canceled the repair appointment.

Parts Used:

-

Rodger from Wilmette, IL

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

13 of 17 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!