DLB2880BAC Hotpoint Dryer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

loud squeeking noise when dryer was runnig

nd removed it from the unit.

5. replaced drum bearings

6. reassembled everything in the same order I took it off.

Be sure to mark any wires you may disconnect to ensure you connect them back correctly.

Was a bit frustrating at times, but made it through and there is no more squeek.

5. replaced drum bearings

6. reassembled everything in the same order I took it off.

Be sure to mark any wires you may disconnect to ensure you connect them back correctly.

Was a bit frustrating at times, but made it through and there is no more squeek.

Parts Used:

-

Joel from Greenville, IL

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers

0 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer was making a vibrating sound near the bottom left rear area.

I suspected the idler pulley shaft was worn. I found the repalcement pulley on parts select web site. finding the part was very easy and delivery was very quick. After removing the dryer from the wall,I removed the access panel in the rear which exposed the motor, belt, and pulley. After removing the belt from the pulley, I removed the pully assembly from the dryer. I removed the keeper retaining ring on the pulley and installed the new pulley with the new parts supplied. The new pulley assembly was then ready for re-installation.

Parts Used:

-

RICHARD from ST. MARTINVILLE, LA

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers

Was this instruction helpful to you?

Thank you for voting!

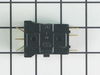

Dryer would not start and the smell of an electrical part burning.

What to do if you have a load of wet laundry at 23:00, the dryer won’t start, and you have no spare start switch.

Removed rear access panel and discovered the wire from terminal #2 (goes to heater coils) on the start switch had melted and disconnected. The start switch showed signs of overheating but not melted. Removed the switch and found the switch’s actuator button was jammed in the ‘in’ position (dryer won't start). The switch was a friendly one in that it was possible to disassemble it. Most switches today are molded/glued together, but this one could be pried apart. The contacts inside were still in fair condition and, after dressing them, the switch was reassembled. The actuator button had a burr that was filed off and the switch action worked fine. All of the 1/4" male QC contacts on the switch were cleaned with a wire brush. The burned wire was cut back about 6” and a new piece of 14ga wire was spliced in with a wire nut. A new 1/4” QC terminal was crimped to the wire and all wires were re-attached to the switch.

This fix would probably last for a long time to come, but I bought a new switch and installed it and will keep the old switch as a backup.

p.s. The load of laundry was dry by 02:00.

Removed rear access panel and discovered the wire from terminal #2 (goes to heater coils) on the start switch had melted and disconnected. The start switch showed signs of overheating but not melted. Removed the switch and found the switch’s actuator button was jammed in the ‘in’ position (dryer won't start). The switch was a friendly one in that it was possible to disassemble it. Most switches today are molded/glued together, but this one could be pried apart. The contacts inside were still in fair condition and, after dressing them, the switch was reassembled. The actuator button had a burr that was filed off and the switch action worked fine. All of the 1/4" male QC contacts on the switch were cleaned with a wire brush. The burned wire was cut back about 6” and a new piece of 14ga wire was spliced in with a wire nut. A new 1/4” QC terminal was crimped to the wire and all wires were re-attached to the switch.

This fix would probably last for a long time to come, but I bought a new switch and installed it and will keep the old switch as a backup.

p.s. The load of laundry was dry by 02:00.

Parts Used:

-

Randy from FREMONT, CA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers

Was this instruction helpful to you?

Thank you for voting!

Dryer Completly Stopped Running

I have had this happen to another ge dryer, so I had an idea what was wrong. After taking the 4 torx screws out from under the front lip of dryer top, lifting the top back (like opening the hood of your car) in the back right corner is where the high limit tstat is. To verify the problem (dryer already unpluged of course) pull the two wires off the terminals of tstat, connect them together, wrap bare parts w/ electrical tape. Let top down & plug dryer in-- it started& ran fine. Got online and ordered replacement tstat (it arrived in 2 days-- great!) unscrewed the two 1/4" hex screws holding tstat on, installed new part. On to bigger and better things ! Dryer working fine.

Parts Used:

-

Ronald from Gatesville, TX

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver

Was this instruction helpful to you?

Thank you for voting!

The dryer door wouldn't stay closed.

There is a plastic female closure part in the dryer door that wouldn't close tightly around the metal male closure on the dryer. I popped out the plastic square with a screwdriver, popped the new plastic closure in with my thumb. Works great. I never even installed the new metal portion of the latch.

Parts Used:

-

Jean from Waterford, MI

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

Was this instruction helpful to you?

Thank you for voting!

Dryer Squeeky

-

Elbert from LAWTEY, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

Was this instruction helpful to you?

Thank you for voting!

Loud Sqeaking noise

the replacement part was easy to replace but remembering how the belt went back on took alittle more time..

Parts Used:

-

Michell from Bellefontaine, OH

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

Was this instruction helpful to you?

Thank you for voting!

Loud screeching noise

I watched video supplied from parts select, only took about 30 minutes, hardest part was putting belt back on, couldn't fit hands in easily, but once I did it, dryer is like new, can't hear a thing.

Parts Used:

-

Michael from Hopatcong, NJ

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

Was this instruction helpful to you?

Thank you for voting!

No heat or intermediate heating and cooling.

I replaced the three thermostats first, but still not action on the unit. I then replaced the timer and the machine came to life. It was helpful with the explosion diagrams as you could see what would be needed and where the hidden screws might be. All in all, it went pretty smoothly with common tools.

Parts Used:

-

Brian from Angels Camp, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers, Wrench set

Was this instruction helpful to you?

Thank you for voting!

Holes were not threaded on rear bearing kit

Had to tap three holes in the rear bearing to match the three attachment screws. Screw up with the part.

Parts Used:

-

Dennis G from Naples, FL

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set, Wrench (Adjustable), Wrench set

Was this instruction helpful to you?

Thank you for voting!

idler pulley broken

Pop off the old, pop on the new. I did it with one hand, the 'hard' part was putting the access panal back on.

Parts Used:

-

James from Pottsville, PA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Pliers

Was this instruction helpful to you?

Thank you for voting!

My timer knob cracked after 20 years

Break up the broken knob easily with plyers.Once thats off then push on the new knob with your fingers that took 3 seconds ,fit perfect.

Parts Used:

-

William from Beacon Falls, CT

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

Was this instruction helpful to you?

Thank you for voting!

temperature in dryer erratic.

removed four screws holding top. Swing back top to expose thermostat. emove two push on connectors and two self tapping screws. Instal new thermostat

Parts Used:

-

Robert from Palm Harbor, FL

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver

Was this instruction helpful to you?

Thank you for voting!

squealing noise while dryer was running

Removed two screws from front by door. Removed back panel to remove belt from tensioner. lifted lid of dryer. removed two more screws from inside to remove front panel. while holding the barrel I removed the front panel then grabbed barrel and pulled out. took off the old bearing, put the new one on and reassembled it the way I took it apart. The whole thing took about 10 min was quick and easy if there is any problems while you are doing it look it up on youtube.com and you can see it done.

Parts Used:

-

robert from Florissant, MO

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver, Screw drivers

Was this instruction helpful to you?

Thank you for voting!

not heating

take off door, take off front, mind the 2 wires for the door switch, take off top, take out enough screws on right side so it will lean out a bit for the drum to be removed. before removing drum you must remove the belt. pull the wheel to the right, minding the belt pattern for reassembly, its springy and will relieve tension. pull drum out. look to the left of the pulley and check to see any stray wire that may have pulled out while battling the belt. if you found a stray wire and it reaches the dryer motor find its home. on to the coils. I left assembly on dryer so I didn't have to figure out wire placement. the end connectors that the coils attach to are to be reused so don't get to mean with them. remove the end connectors minding how many wires it has and which of the 2 coils go to it. remove the old coils so as not to damage the very brittle ceramic insulators. on to the new, the instructions will tell you to stretch out the new coils to specified lengths. start with the shorter one first! just to see the stretchiness and how far is too far to stretch, if to long it will touch the heat shield and no good can come of that. after stretched out its time to string new coils in, carefully, so as not to stretch or collapse the coil. now hooking the end connectors to the ends of spring. I used 2 pliers to bend the tab a little bigger so it would cover the spring end. after springs are attached to ends and ends are in place, time to battle the drum and tensioner again, make sure plastic piece is on drum insert if equipped, put drum in place and bend tensioner down and install belt. put side screws on, then front and 2 wires , then top then door. plug in and start up. if unit doesn't start remember that stray wire going to the motor, you guessed it wire goes to the start switch. unplug and hook up the wire and it will work.

Parts Used:

-

rick from sterling, NE

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers

Was this instruction helpful to you?

Thank you for voting!