DLB1550RAL Hotpoint Dryer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Had a lint filter that screen was all worn out

We ordered a new lint filter with white frame from Part Select. Had to take the dryer outside and blow all lint out that had accumulated in the dryer. We then vacumed everything out and brought back in house and put in new lint filter we ordered and used the dryer today and it works beautiful. Saved us from having to buy a new dryer. Thanks Part Select for having the filter we needed. Raymond Kampsen, Vassar, Ks.

Parts Used:

-

Raymond from Vassar, KS

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

16 of 16 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Old drum bearingwore out, squeeking like a banchee

Received part in two days.

Removed inspection plate by removing two screws. .Drum bearing was right there. With screwdriver

removed "c" clip, took out what was left of old bearing.

With screwdriver aligned drum, slide new bearing into place. Job was done. Instruction with new part simple and easy to follow.

Removed inspection plate by removing two screws. .Drum bearing was right there. With screwdriver

removed "c" clip, took out what was left of old bearing.

With screwdriver aligned drum, slide new bearing into place. Job was done. Instruction with new part simple and easy to follow.

Parts Used:

-

JOE from Galion, OH

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Socket set

17 of 19 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

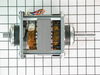

Wouldn't start

Removed the front panel,tiped up the top panel ,removed the drum, drive belt,motor and exaust tube assembly. cleaned and vaccumed all lint from every were. Removed motor from fan blade and houseing. Reinstalled moter and pulley that came with the moter and fan blade. reinstalled all of the rest of the parts and plugedin the wires. once all back together pluged into outlet and turned on and prasto works great.

Parts Used:

-

Pauline from South Portland, ME

-

Difficulty Level:Easy

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Screw drivers

29 of 55 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Drive Belt Replacement needs Drum Modification

To perform this repair (please see numerous descriptions on the web for generic belt replacement) I had to rivet two loose parts to the drum in order to reinstall the drum. Specifically, the loose metal disk and hot air shroud at the rear of the drum (near the rear berrings) made it impossible to realign the parts to reinstall the three torx bolts at the rear of the drum during reassembly. These two loose parts are positioned behind the drum (when looking inside the drum) i.e. between the drum and the rear berrings.

It was necessary to align the mounting holes in the drum, disk, and air shroud outside of the dryer itself and then to rivet them in place (making sure the smooth rivet head was INSIDE the drum as to avoid providing a rough edge where the clothes could catch during tumbling). Just press the 3 torx bolts through the holes to establish correct alignment. Be sure to install the rivets ouside of the contact area between the heat shroud and mounting plate. You should see an indented pattern on the heat shroud that you can use as a guide.

It was also helpful to make a black mark on one of the drum mounting holes (inside the drum) and its mate on the berring attachment plate - to help orient you when installing the drum with the 3 torx bolts. It only aligns one way - and making the marks will save you aggravation while your head is in the drum during reassembly. Loud swearing at this point only punishes your ears because, after all, your head is in an acoustically punishing echo chamber - and the echoes make it seem as if the dryer is actually cussing YOU and your incompetence out...

I hope this helps someone else save some time in reinstalling the drum.

One additional pointer: you must remove the lower plate on the rear side of the dryer to wrap the belt around the tensioner pulley and motor drive. The belt wraps, from right to left, first around the motor pulley and then up and to the left around the tensioner pulley. Just place the belt around the motor pulley, and then pull the tensioner pulley toward you and leftward until it clears the belt, then push toward the front of the dryer - and let the tensioner contact the belt on the right side of the tensioner pulley.

And finally, the ribbed side of the belt makes contact with the drum and the motor pulley. The smooth side of the belt is in contact with the tensioner pulley. Good luck, and may the choice words I used during the process be unnecessary for you... for you... for you!

It was necessary to align the mounting holes in the drum, disk, and air shroud outside of the dryer itself and then to rivet them in place (making sure the smooth rivet head was INSIDE the drum as to avoid providing a rough edge where the clothes could catch during tumbling). Just press the 3 torx bolts through the holes to establish correct alignment. Be sure to install the rivets ouside of the contact area between the heat shroud and mounting plate. You should see an indented pattern on the heat shroud that you can use as a guide.

It was also helpful to make a black mark on one of the drum mounting holes (inside the drum) and its mate on the berring attachment plate - to help orient you when installing the drum with the 3 torx bolts. It only aligns one way - and making the marks will save you aggravation while your head is in the drum during reassembly. Loud swearing at this point only punishes your ears because, after all, your head is in an acoustically punishing echo chamber - and the echoes make it seem as if the dryer is actually cussing YOU and your incompetence out...

I hope this helps someone else save some time in reinstalling the drum.

One additional pointer: you must remove the lower plate on the rear side of the dryer to wrap the belt around the tensioner pulley and motor drive. The belt wraps, from right to left, first around the motor pulley and then up and to the left around the tensioner pulley. Just place the belt around the motor pulley, and then pull the tensioner pulley toward you and leftward until it clears the belt, then push toward the front of the dryer - and let the tensioner contact the belt on the right side of the tensioner pulley.

And finally, the ribbed side of the belt makes contact with the drum and the motor pulley. The smooth side of the belt is in contact with the tensioner pulley. Good luck, and may the choice words I used during the process be unnecessary for you... for you... for you!

Parts Used:

-

John from Windham, NH

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers, Socket set

18 of 25 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Door wouldn't stay shut

When I went home at Christmas, I saw that my Mom had been using a small bench to keep her dryer door shut. I wrote the make / model of the dryer down and found your website. I ordered the part, and my sister snapped it into place. My mom was so happy to have her dryer door stay shut again!

Parts Used:

-

Catherine from Windber, PA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers

18 of 25 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

broken belt

Belt and pulley both broke. Ordered parts; received 2 days later. Took off front and top, positioned belt, replaced pulley and nut. Parts fit perfectly. Reinstalled covers. Ran dryer. Easy fix.

Parts Used:

-

Joseph from Girard, OH

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Wrench set

20 of 32 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

squeeling dryer

pulled off door, front panel and rear access panel. unscrewed drum. cleaned every thing. removed and replaced front slides, belt idler pulley and rear bearing. Reassembled everything. Dryer is as quiet as a it was when brand new.

Parts Used:

-

Dean from Mahtomedi, MN

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Socket set

20 of 33 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer making incredibly loud squeaking noise as it heated up

Replaced drum bearings, adjusted screw levelers trying to find the source of the noise. It was hard tracking it down. Finally lubricated the drum slides with WD40 and it resolved the problem for a couple days. Decided to try replacing the drum slides. The old ones did not look worn out - still had teflon surfaces - it was not metal on metal like I suspected. But when I got the replacement parts, there were 2 tubes of lubricant with notes that only this specific lubricant needed to be used on these slides. The teflon slides have a fiber material under them, and soaks up the lubricant. Problem appears to be solved. Whether it would be possible to purchase the lubricant only (since the slides looked OK) might be a question, however, the replacement kit cost was reasonable given that it solved the problem.

Parts Used:

-

Kenneth L from Chesterland, OH

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver

14 of 16 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

latch on door broken, dryer could not function

I just pressed the latch with my thumb, the latch went in, and voila....job done. Thank you

Parts Used:

-

blanche from Delray Beach, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

19 of 36 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

old belt broke

my two twin boys Mike and Curtis age 14 did the repare they toke of the front of the dryer then the top put the belt around the drum then put the top and front back on then went to the back and removed the panel and put the belt on the pulley then set the tension wheel then put the back cover back on

the repair was easy I watched to make sure they did it right and did not have to tell them how I am very proud of them they do great work

finding the part was easy and it was here the next day after I ordered it and it was only sent 3 to 5 work days. You guys have a great web site and fast shipping thanks for the good work!

the repair was easy I watched to make sure they did it right and did not have to tell them how I am very proud of them they do great work

finding the part was easy and it was here the next day after I ordered it and it was only sent 3 to 5 work days. You guys have a great web site and fast shipping thanks for the good work!

Parts Used:

-

bob from shoemakersville, PA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set

12 of 15 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Clothes pinching between the drum and door opening.

The drum slides on my dryer had worn down to the point that an opening formed that allowed clothes to enter the gap and get pinched between the spinning drum and the door. This would leave a mark and sometimes a cut on the clothes. To repair: open the door and undo the screws above the door opening that hold the top on the dryer. It's hinged in the back so it swings up from the front once the screws are removed. Undo hex head screws on either side at the top that hold on the front of the dryer. Also loosened the same at the bottom of the front panel (includes the door). Pull the front off of the dryer. This exposes the drum slides on either side in the front of the drum. They're fastened to the frame of the dryer. Undo the hex head screws (2 each) and remove drum slide, then replace. I recommend one slide at a time so the other one helps hold the dryer in place. The kit includes both slides. Pretty easy once I discovered how worn the old slides were! The drum turns much easier and quieter now too!

Parts Used:

-

Curtis from Natchez, MS

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

11 of 14 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Broken Dryer belt

Easy as 1-2-3. I took off the top hinge screws in order to lift up the top of the dryer.

I then took off the front dryer piece with the door intact. The lint filter was in the front door section.

I released the wiring clips to the front of the dryer and lowered the front of the dryer down gently. there is enough slack with the wiring if you disconnect the wirre clips.

I removed the old broken belt. ThenI gently lifted thr dryer drum enough to slid in the new belt with the ridges down. Look for the old belt line (worn area on the drum) and slip the belt up on the drum to that point.

Then I replaced the wiring with clips and put the front of the dryer back together.

Going around to the lower back of the dryer, I unscrewed the back plate where the exhaust comes out. It was 8 screws with a socket.

Once the back was off, I pulled the dryer pully to the right and fed the reamider of the belt through both pulleys ensuring that the ridged side was on the correct side of the pulley. The pylleys match the ridges on the belt. I rleased the tension on the movavle pulley and it was done.

All I had to do was button the back up and do a "dry run" I quick have the drum a half roation from inside the drum with the door open. Then it was all gravy. I was done and saved myself a good deal of money. Look on the net for pics to make thing easier for you. There are people out ther who will NOT charge you for this info.

I then took off the front dryer piece with the door intact. The lint filter was in the front door section.

I released the wiring clips to the front of the dryer and lowered the front of the dryer down gently. there is enough slack with the wiring if you disconnect the wirre clips.

I removed the old broken belt. ThenI gently lifted thr dryer drum enough to slid in the new belt with the ridges down. Look for the old belt line (worn area on the drum) and slip the belt up on the drum to that point.

Then I replaced the wiring with clips and put the front of the dryer back together.

Going around to the lower back of the dryer, I unscrewed the back plate where the exhaust comes out. It was 8 screws with a socket.

Once the back was off, I pulled the dryer pully to the right and fed the reamider of the belt through both pulleys ensuring that the ridged side was on the correct side of the pulley. The pylleys match the ridges on the belt. I rleased the tension on the movavle pulley and it was done.

All I had to do was button the back up and do a "dry run" I quick have the drum a half roation from inside the drum with the door open. Then it was all gravy. I was done and saved myself a good deal of money. Look on the net for pics to make thing easier for you. There are people out ther who will NOT charge you for this info.

Parts Used:

-

Bruce from Taylor, PA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Socket set

9 of 9 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

broken dryer belt

First i removed the lower rear inspection plate to see what the problem was.

next i removed the screws in the front top panel.

next i lift the top back,the rear hinges held it in place.

next i removed the bolts that held the front panel in place,but before i removed the panel i removed the wires that were connected to the front elements and disconnected then,

next i removed the front panel,then i place the new dryer belt over the dryer drum,but first you have to rise the drum up a little to get the belt under it.

next i put all the front panels back in place,make sure you reconnect the wires that you removed earlier.

next i moved to the back panel, there i position the belt over the dryer drum,then i place the belt over the motor drive pulley, then i pull down the tension bar roller to the left and place the belt over it.Then i replace the rear panel in place.plug in the power core and turn it on. finished. After over 35 years this is the first time i had to replace the belt,matter of fact this is the first time i had to replace anything on this dryer, washers will that is a different story. but the dryer runs great maybe for another 30 +years LOL.

next i removed the screws in the front top panel.

next i lift the top back,the rear hinges held it in place.

next i removed the bolts that held the front panel in place,but before i removed the panel i removed the wires that were connected to the front elements and disconnected then,

next i removed the front panel,then i place the new dryer belt over the dryer drum,but first you have to rise the drum up a little to get the belt under it.

next i put all the front panels back in place,make sure you reconnect the wires that you removed earlier.

next i moved to the back panel, there i position the belt over the dryer drum,then i place the belt over the motor drive pulley, then i pull down the tension bar roller to the left and place the belt over it.Then i replace the rear panel in place.plug in the power core and turn it on. finished. After over 35 years this is the first time i had to replace the belt,matter of fact this is the first time i had to replace anything on this dryer, washers will that is a different story. but the dryer runs great maybe for another 30 +years LOL.

Parts Used:

-

alfred from copperas cove, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Socket set, Wrench set

11 of 15 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer Belt Broke

Removed the rear access panel (8 - 10 bolts), checked the pullys. Opened the dryer door, removed 4 allen screws at top and lifted the top of the dryer (like a hood on a car). Removed a screw (phillips) on each side (inside) pulled open the front and worked the belt around the drum. Placed belt onto pullys, plugged in checked for proper rotation of drum then unplugged and installed screws and bolts. - Fairly easy, saved a bunch from a service call. I also found 15+ years of lint inside the dryer. Vacumed and cleaned the inside -it even dries faster! Sorry Honey - No new dryer this year - Now can I go hunting?

Parts Used:

-

James from Sylacauga, AL

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver

9 of 10 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

extremely loud continous noise when drying laundry

watched the video on your website,this made repair to the dryer very easy.hardest step in the repair was getting the belt hooked up on motor and tensioner,but being old and persistent i finally won!

Parts Used:

-

wayne from waterloo, NY

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers, Socket set, Wrench (Adjustable)

9 of 10 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!